设计简介

摘 要

本文首先对钻机转筒零件进行分析,通过对钻机转筒进行的研究和分析,描述了它的毛坯制造形式、机械加工余量、基准选择、工序尺寸和毛坯尺寸的确定,以及切削用量和工时的计算等相关内容。为了提高劳动生产率,降低劳动强度,保证加工质量,与指导老协商后,觉得用夹具比较合适。

在这次毕业设计中,根据课题所给的零件图、技术要求,通过查阅相关资料和书籍,了解和掌握了的机械加工工艺的一般方法和步骤,并运用这些方法和步骤进行了钻机转筒的机械加工工艺及夹具设计。整个设计的指导思想“简便、高效、经济”。力求生产处符合要求的产品。

关键词:钻机转筒;加工工艺;夹紧;夹具

ABSTRACT

本文首先对钻机转筒零件进行分析,通过对钻机转筒进行的研究和分析,描述了它的毛坯制造形式、机械加工余量、基准选择、工序尺寸和毛坯尺寸的确定,以及切削用量和工时的计算等相关内容。为了提高劳动生产率,降低劳动强度,保证加工质量,与指导老协商后,觉得用夹具比较合适。

在这次毕业设计中,根据课题所给的零件图、技术要求,通过查阅相关资料和书籍,了解和掌握了的机械加工工艺的一般方法和步骤,并运用这些方法和步骤进行了钻机转筒的机械加工工艺及夹具设计。整个设计的指导思想“简便、高效、经济”。力求生产处符合要求的产品。

关键词:钻机转筒;加工工艺;夹紧;夹具

ABSTRACT

This design is a lather to become soon an appropriation for inside pulling out fork spare parts processing craft rules distance and some work prefaces tongs design.This pull out the construction of the fork spare parts than for complicacy, its the place that process is a peaceful in bore primarily.This design processes after processing first the bore.Process with flat surface the clear and definite dividing the line the bore the coarseness processes to process with the nicety the stage to guarantee their process the precise degree.The basis choice to pull out rough basis of conduct and actions of the biggest flat surface of the right in fork, process the in the

This paper is describe processing primarily work preface arrangement is first to process a flat surface with the center bore fixed position with the right side flat surface and below big bore of two flat surface, again with center bore the fixed position processes the big bore that carry down.While processing is to use the boring machine boring bore.Regard these two bores as the basis finally, process the right-hand slot respectively with the thread bottom bore of the a.Whole processes the process chose to use to the drill machine, miller with the boring machine .The tongs chooses to use the appropriation tongs.

KEY WORDS : Process the craft;Fixed position;turede tapd;Appropriation tongs

目录

摘要 IThis paper is describe processing primarily work preface arrangement is first to process a flat surface with the center bore fixed position with the right side flat surface and below big bore of two flat surface, again with center bore the fixed position processes the big bore that carry down.While processing is to use the boring machine boring bore.Regard these two bores as the basis finally, process the right-hand slot respectively with the thread bottom bore of the a.Whole processes the process chose to use to the drill machine, miller with the boring machine .The tongs chooses to use the appropriation tongs.

KEY WORDS : Process the craft;Fixed position;turede tapd;Appropriation tongs

目录

ABSTRACT II

第一章 绪论 1

1.1课题背景 1

1.2夹具的发展史 1

第二章 钻机转筒的加工工艺规程设计 2

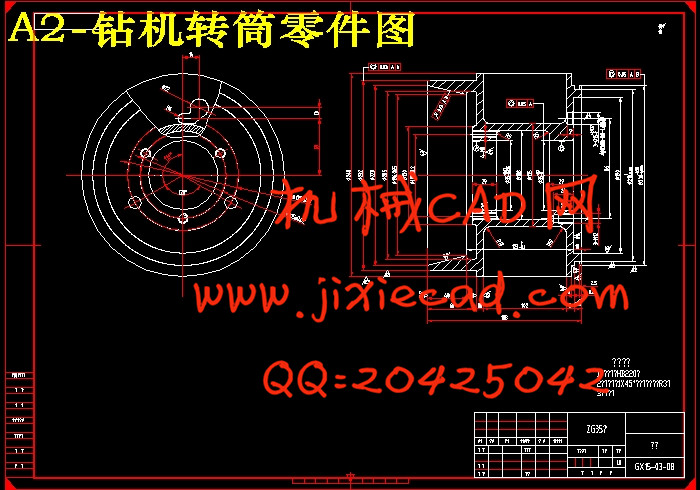

2.1零件的分析 2

2.1.1零件的作用 3

2.1.2零件的工艺分析 4

2.2确定生产类型 8

2.3确定毛坯 12

2.3.1确定毛坯种类 13

2.3.2确定铸件加工余量及形状 15

2.3.3绘制铸件毛坯图 17

2.4工艺规程设计 18

2.4.1选择定位基准 18

2.4.2制定工艺路线 18

2.4.3选择加工设备和工艺设备 19

2.4.4机械加工余量、工序尺寸及公差的确定 19

2.5确定切削用量及基本工时 19

2.5.1工序30:粗车

2.5.2工序40:调头装夹,粗车

2.5.3工序50:粗车

2.5.4工序60:粗车,半精车

2.5.5工序70:粗、精镗左端内孔

2.5.6工序80:粗、精镗右端内孔

2.5.7工序90:铣

2.5.8工序100:钻、攻左端面上4-M8螺纹孔 25

2.5.9工序110:钻、绞右端面

第三章 专用夹具设计 27

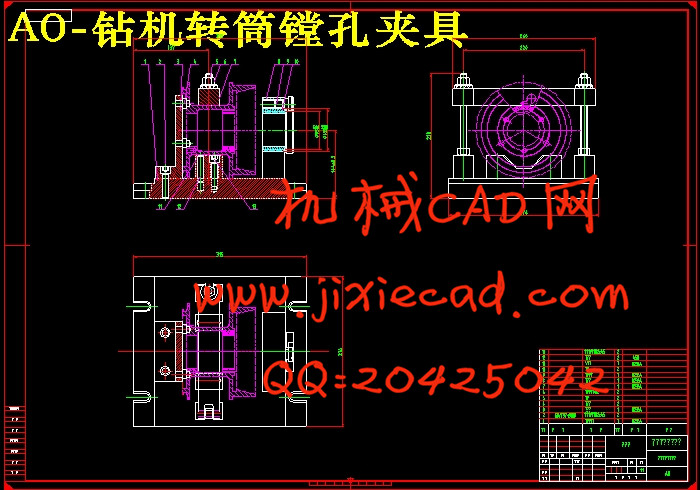

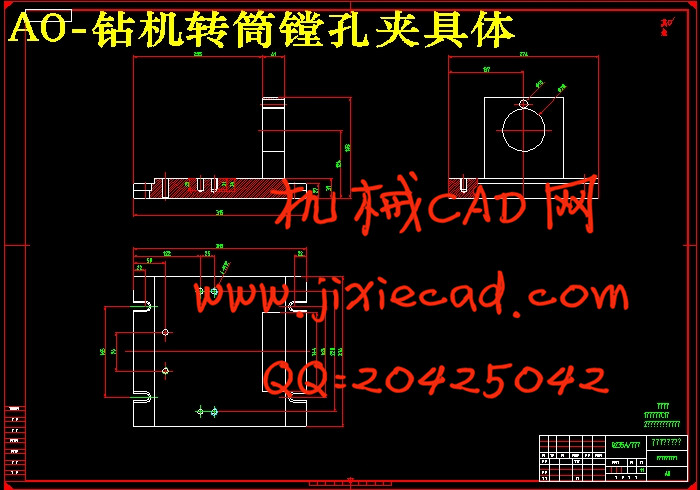

3.1镗孔夹具设计 27

3.1.1问题的提出 28

3.1.2夹具的设计 29

3.2钻孔夹具设计 30

3.2.1问题的提出 31

3.2.2夹具的设计 32

结论 33

参考文献 34

致谢 3