设计简介

摘 要

在制定工艺过程中,要确定各工序的安装工位和该工序需要的工步,加工该工序的机车及机床的进给量,切削深度,主轴转速和切削速度,该工序的夹具,刀具及量具,还有走刀次数和走刀长度,最后计算该工序的基本时间,辅助时间和工作地服务时间。

本次设计的主要内容是泵体加工工艺规程及

关键词: 工序;工艺;工步;加工余量

ABSTRACT

Enable producing the target in process of production (raw materials, the blank , state of quality and quantity on part become always ) take place direct course of change ask craft course, if the blank is made, machining, heat treatment t can replace the heavy labor in order to achieve the production mechanization and automation, and can work in dangerous working environments to protect the personal safety, Therefore widely used in machine building, metallurgy, electronics, light industry and atomic energy sectors.of the direction, and only one direction 48 hole feed.This paper introduces the basic principle and the classification of interpolation, principle of point by point comparison method, the visual of development environment and drawing function introduction. Using the top framework of visual in of, based on the 12 hole developed a parabolic interpolation of point by point comparison method, which can further the understanding to the characteristics of point by point comparison method and the further understanding of the development tools, for the further numerical fields.Under the global economic development environment,China's various industries in other countries by the advanced technology of impact at the same time.

Keywords: The process, worker one, worker, the surplus of processing

目录

Abstract IV

1 绪 论 1

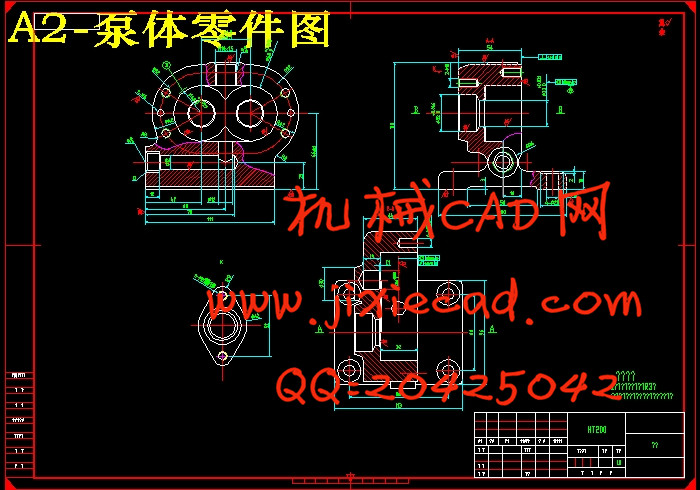

2 零件的分析 1

2.1 零件的作用 2

2.2 零件的工艺分析 5

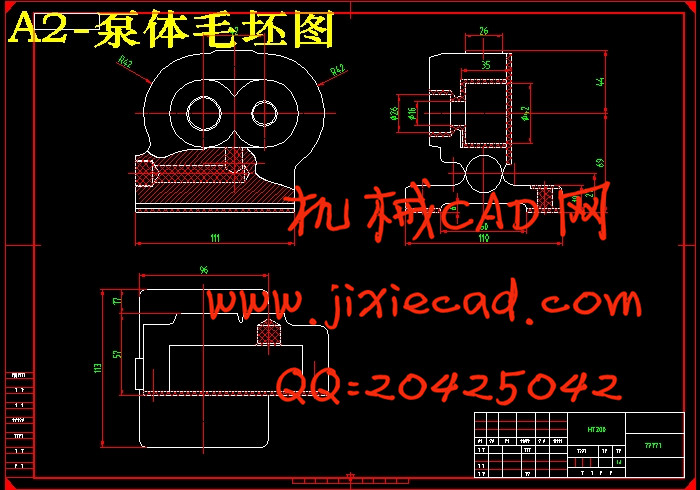

3 毛坯的确定以及毛坯图和零件图的绘出 8

3.1 分析毛坯的制作以及其组成 10

3.2 加工余量和工序、毛坯尺寸的确定 16

4 泵体的工艺规程的设计 19

4.1 定位基准的选择 22

4.2 制订工艺路线 24

4.3 选择加工设备及刀具、夹具、量具 26

4.4 加工工序设计 27

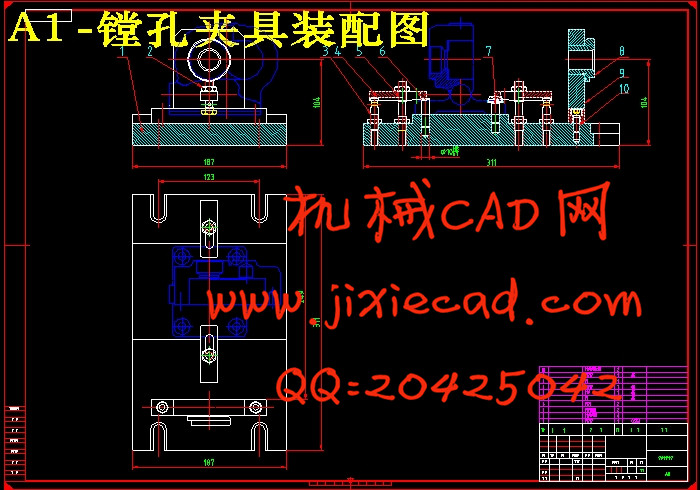

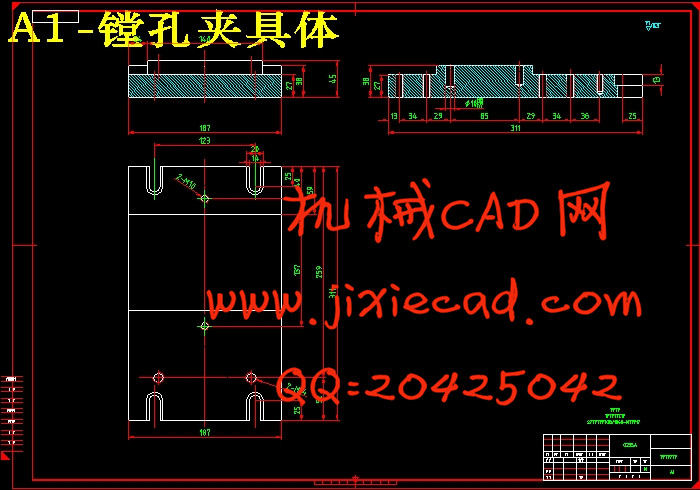

5 设计泵体镗孔夹具 28

5.1 定位基准的选择 29

5.2 分析误差 32

5.3 夹具的夹紧力和切削力的计算 33

5.4 镗套与衬套的设计 35

5.5 夹紧元件及动力装置确定 36

5.6 夹具设计及操作的简要说明 38

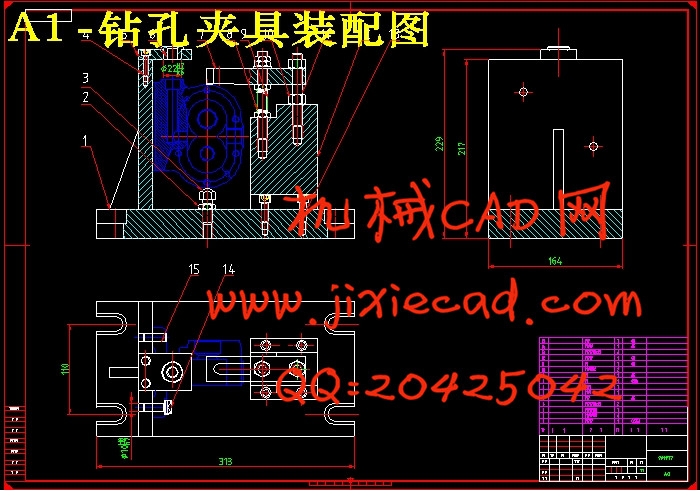

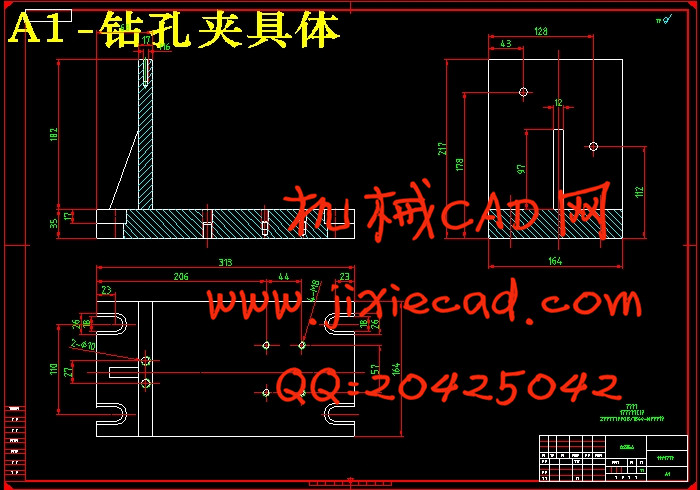

6 设计泵体钻孔夹具 38

结轮 40

致 谢 41

参考文献 42