设计简介

齿轮设计及齿轮工艺设计

摘 要: 齿轮加工机床是加工各种圆柱齿轮、锥齿轮和其他带齿零件齿部的机床。齿轮加工机床的品种规格繁多,有加工几毫米直径齿轮的小型机床,加工十几米直径齿轮的大型机床,还有大量生产用的高效机床和加工精密齿轮的高精度机床。齿轮加工机床广泛应用在汽车、拖拉机、机床、工程机械、矿山机械、冶金机械、石油、仪表、飞机和航天器等各种机械制造业中。

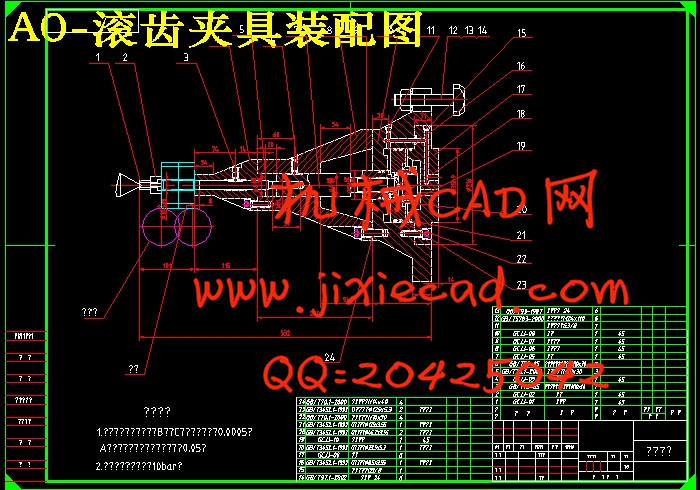

本次设计的题目是齿轮的设计及齿轮加工工艺设计。首先根据工况要求设计齿轮,再对齿轮进行工艺设计,进而确定设计的总体布局,随后,对滚齿夹具进行设计。

关键词:齿轮,滚齿机,加工工艺,滚齿夹具。

Gear gear design and process design

Abstract: Processing a variety of gear cutting machines are cylindrical gears, bevel gears and other parts with teeth teeth of the machine. Variety of gear cutting machines of many specifications, there are a few millimeters in diameter gear of the small processing machine tools, processing ten meters of large diameter gear machine tools, there are a large number of production and processing of high-precision gear machine precision machine tools. Gear cutting machines are widely used in automobiles, tractors, machine tools, construction machinery, mining machinery, metallurgical machinery, petroleum, instrumentation, aircraft and spacecraft and other machinery manufacturing.

The subject is designed to gear design and gear machining process design. First, to design the gear according to conditions, then the gear design process, and to determine the overall layout design, then, for hobbing fixture design

Keywords: Gear hobbing machine, processing technology, gear hobbing fixture

目 录

1、绪论………………………………………………………4

1.1齿轮发展历史………………………………………………..4

1.2我国齿轮发展现状………………………………………..….4

1.3齿轮制造技术现状…………………………………………...5

2、齿轮设计与计算…………………………………………9

2.1齿轮参数确定……………………………………………………9

2.2齿面接触疲劳强度计算………………………………………..11

2.3齿根弯曲疲劳强度计算………………………………………13

3、齿轮毛坯与计算……………………………………….15

3.1毛坯的选择………………………………………………………15

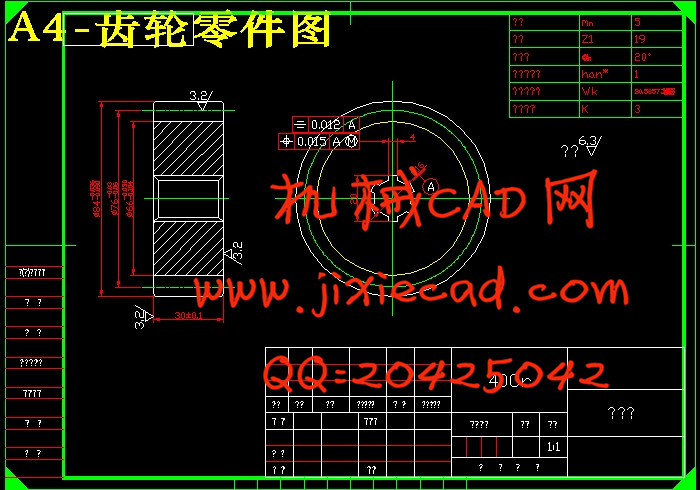

3.2齿轮的计算…………………………………………….................15

4、齿轮加工工艺分析……………………………………17

4.1圆柱齿轮加工工艺程的内容和要求……………………………17

5、滚齿夹具的设计………………………………………..20

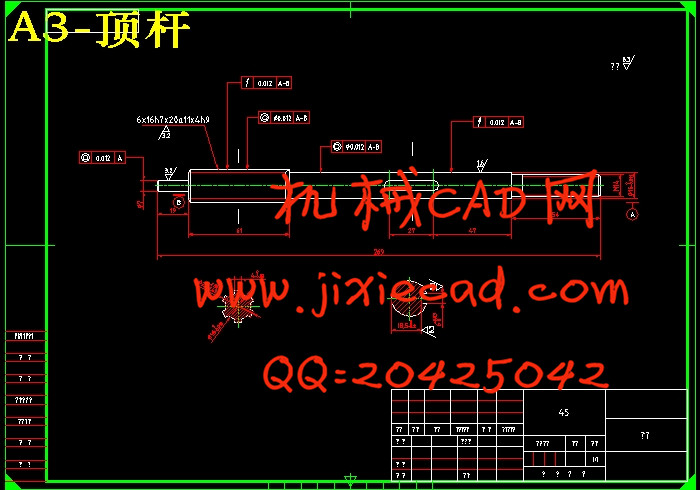

5.1顶针芯轴…………………………………………………………20

5.2花档芯轴…………………………………………………………20

6、结论……………………………………………………...21

参考文献…………………………………………………24

致谢………………………………………………………25