设计简介

摘要

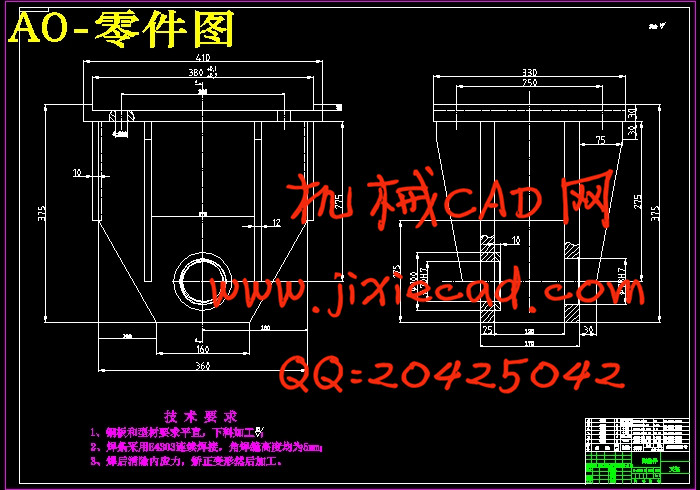

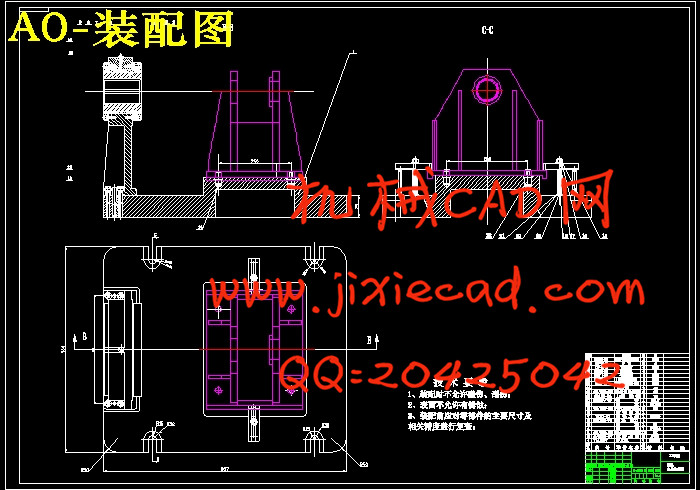

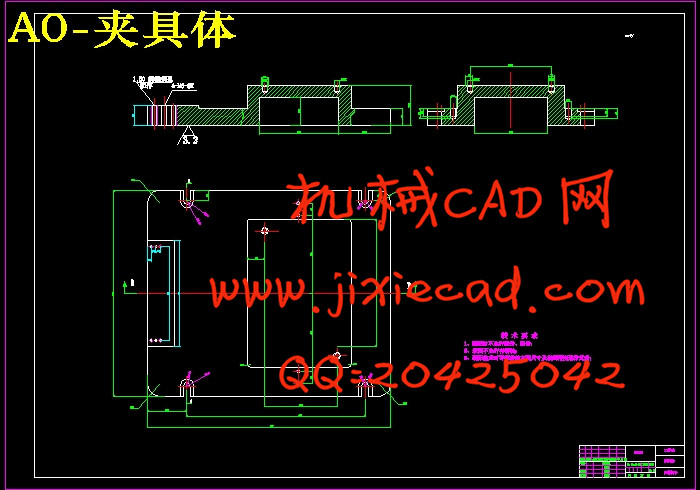

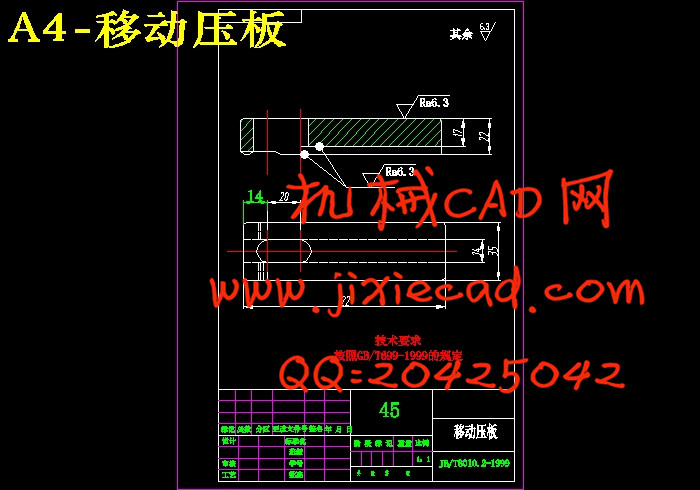

本文主要讲述叉架零件的加工工艺,通过开篇对其零件图纸进行工艺分析,然后设计出毛坯,制定出加工工艺路线,分析工序尺寸与确定公差,选择加工设备,再到夹具、刀具、量具的设计,设计的重点是选定零件钻孔夹具,通过CAD设计软件对钻床夹具进行绘制设计,然后将各零件进行装配,完成设计,以及利用对夹具进行虚拟制造。因此本文要全面的多方位的介绍cad软件,并详细对各个零件的设计与绘制的过程。进行专 用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、叉架与机床的连接部件以及其它部件;计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。关键词:工艺分析;加工方案;切削用量;孔夹具

ABSTRACT

The processing technology of this paper describes the main crotch parts, through the opening on the drawing process are analyzed, and then design a blank, formulate the process route, process dimension and tolerance analysis to determine, selection of machining equipment, and then to the design of fixture, cutting tool, measuring tool, the design focuses on selected parts of drilling fixture, drilling fixture drawing design through the CAD design software, and then the part assembly, complete the design, and the use of virtual manufacturing fixture. This paper introduces the multidimensional should fully CAD software, and the detailed design of each part and drawing process. Special fixture design, fixture for the various components of the design, such as the connecting part positioning device, clamping device, a guide element, clamp and the machine tool and other components; calculate fixture positioning errors when positioning, reasonableness and shortcomings of fixture structure, pay attention to improving and will design in.

Keywords: process analysis; process plan; cutting parameters; drilling fixture

目 录

摘 要 1

1绪论 1

2 零件的图样分析 3

2.1 零件的结构特点分析 3

2.2 零件的技术要求分析 3

3 零件的工艺规程设计 4

3.1 毛坯的选择 4

3.2 定位基准的选择 4

3.3 装夹方式的选择 5

3.4 加工顺序的安排 5

4 设备及其工艺装备的确定 6

4.1 机床的选择 6

4.2 刀具的选择 7

5确定切削用量 9

6 工时计算 15

7 镗φ70H7、φ78H7的中心大孔夹具设计 17

7.1 研究原始质料 17

7.2 设计要求 17

7.3 夹具的组成 18

7.4 夹具的分类和作用 18

7.5 定位、夹紧方案的选择 20

7.6 夹具的导向 21

7.7孔与工件之间的切屑间隙 22

7.8 镗模板 23

7.9定位误差的分析 23

7.10 确定叉架结构和总体结构 24

7.11 夹具设计及操作的简要说明 25

总 结 26

致 谢 27

参 考 文 献 28