设计简介

摘 要

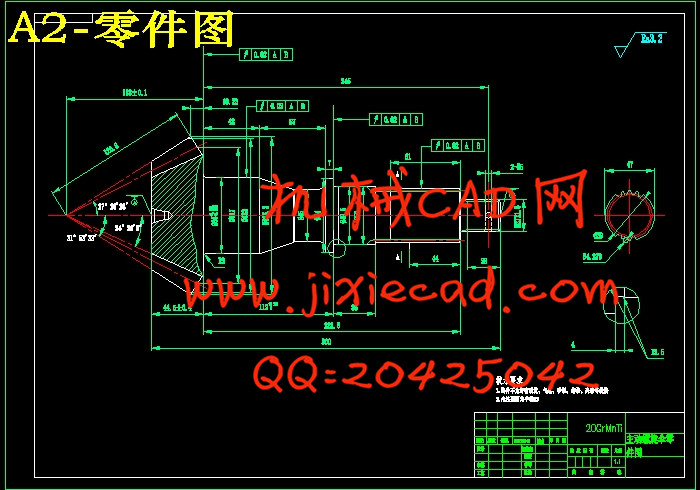

本设计是基于螺旋伞齿轮零件的加工工艺规程及一些工序的专用夹具设计。螺旋伞齿轮零件的主要加工表面是外圆及孔系。一般来说,保证平面的加工精度要比保证孔系的加工精度容易。因此,本设计遵循先面后槽的原则。并将孔与平面的加工明确划分成粗加工和精加工阶段以保证孔系加工精度。主要加工工序安排是先以支承孔系定位加工出顶平面,在后续工序中除个别工序外均用顶平面和工艺孔定位加工其他孔系与平面。夹具选用专用夹具,夹紧方式多选用手动夹紧,夹紧可靠,机构可以不必自锁。因此生产效率较高。适用于大批量、流水线上加工。能够满足设计要求。

关键词:螺旋伞齿轮零件;工艺;夹具;

本设计是基于螺旋伞齿轮零件的加工工艺规程及一些工序的专用夹具设计。螺旋伞齿轮零件的主要加工表面是外圆及孔系。一般来说,保证平面的加工精度要比保证孔系的加工精度容易。因此,本设计遵循先面后槽的原则。并将孔与平面的加工明确划分成粗加工和精加工阶段以保证孔系加工精度。主要加工工序安排是先以支承孔系定位加工出顶平面,在后续工序中除个别工序外均用顶平面和工艺孔定位加工其他孔系与平面。夹具选用专用夹具,夹紧方式多选用手动夹紧,夹紧可靠,机构可以不必自锁。因此生产效率较高。适用于大批量、流水线上加工。能够满足设计要求。

关键词:螺旋伞齿轮零件;工艺;夹具;

Abstract

The design of special fixture manufacturing process of spiral bevel gear parts and process design based on. The main processing surface of spiral bevel gear parts of the outer circle and holes. In general, ensure the machining accuracy of plane than to ensure the accuracy of the processing easily. Therefore, follow the groove surface after the first principle of the design. And the hole and the plane processing clearly divided into roughing and finishing stages to ensure machining precision. The main process of machining technology is first to support hole positioning processing the top plane, in addition to the follow-up processes are individual processes with the top plane positioning technology and other processing Kong and plane. The special fixture fixture, clamping means more choice of manual clamping, clamping reliable, agencies can not self-locking. Therefore, higher production efficiency. Suitable for large batch, the processing pipeline. Can meet the design requirements.

Keywords: spiral bevel gear parts; technology; fixture;

目 录

1螺旋伞齿轮加工工艺规程设计 1The design of special fixture manufacturing process of spiral bevel gear parts and process design based on. The main processing surface of spiral bevel gear parts of the outer circle and holes. In general, ensure the machining accuracy of plane than to ensure the accuracy of the processing easily. Therefore, follow the groove surface after the first principle of the design. And the hole and the plane processing clearly divided into roughing and finishing stages to ensure machining precision. The main process of machining technology is first to support hole positioning processing the top plane, in addition to the follow-up processes are individual processes with the top plane positioning technology and other processing Kong and plane. The special fixture fixture, clamping means more choice of manual clamping, clamping reliable, agencies can not self-locking. Therefore, higher production efficiency. Suitable for large batch, the processing pipeline. Can meet the design requirements.

Keywords: spiral bevel gear parts; technology; fixture;

目 录

1.1零件的作用 1

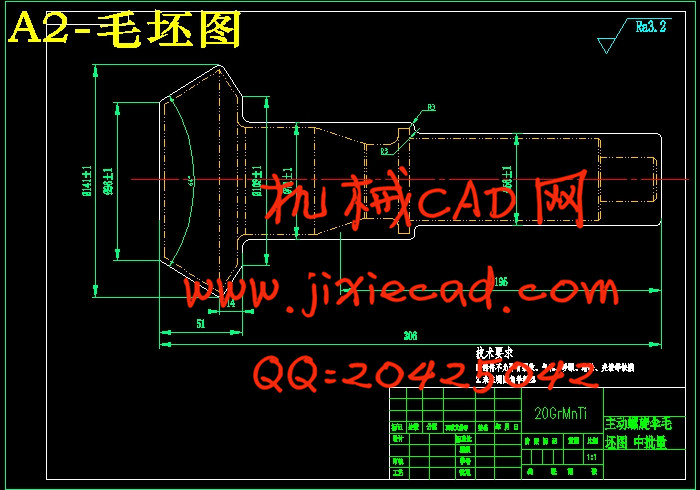

1.2毛坯的选择与尺寸的确定和精度确定 3

1.3螺旋伞齿轮加工的主要问题和工艺过程设计所应采取的相应措施 4

1.3.1孔和平面的加工顺序 4

1.3.2加工方案选择 4

1.4螺旋伞齿轮加工定位基准的选择 5

1.4.1粗基准的选择 5

1.4.2精基准的选择 5

1.5加工主要工序安排 6

1.6工艺路线的确定 6

1.7制订机械加工工艺路线 7

1.8确定各工序切削用量和加工余量 8

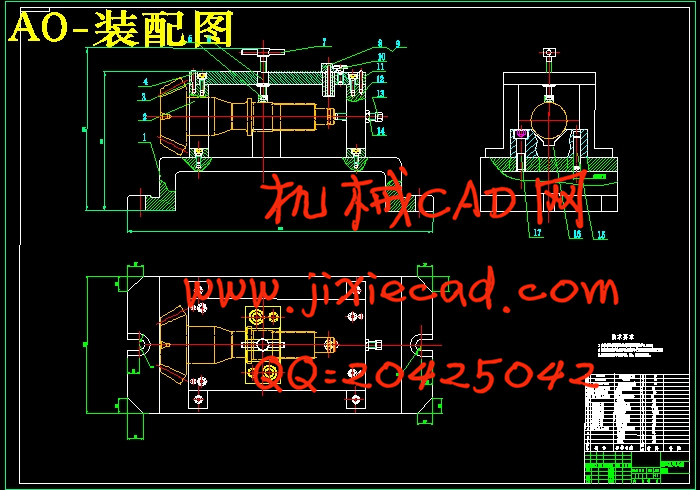

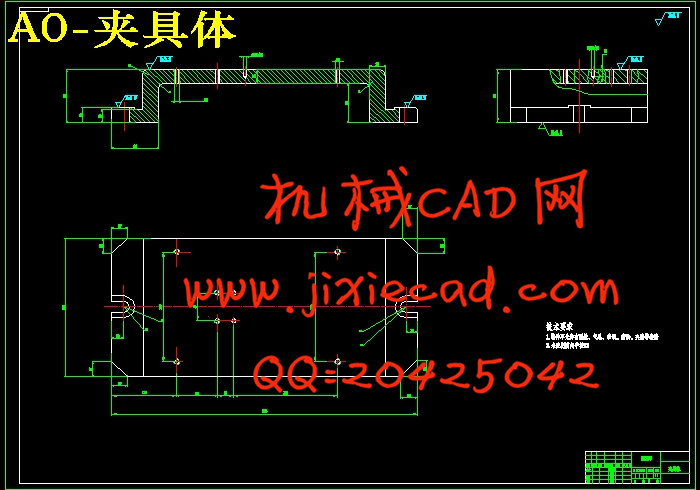

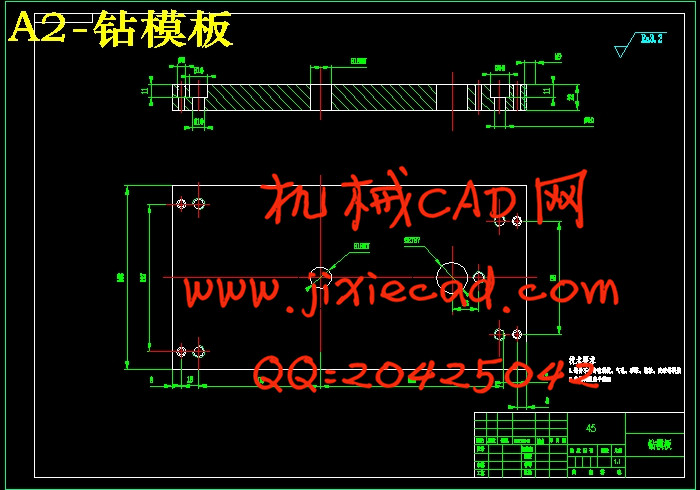

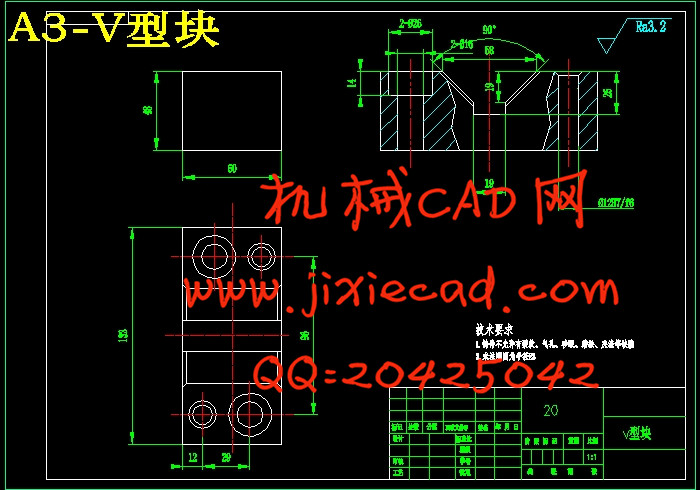

2钻φ5孔夹具设计 13

2.1设计要求 13

2.2夹具设计 13

2.2.1定位基准的选择 13

2.2.2切削力及夹紧力的计算 13

2.3定位误差的分析 17

2.4夹具设计及操作的简要说明 18

结 论 19

参考文献 20

致 谢 22