设计简介

摘要

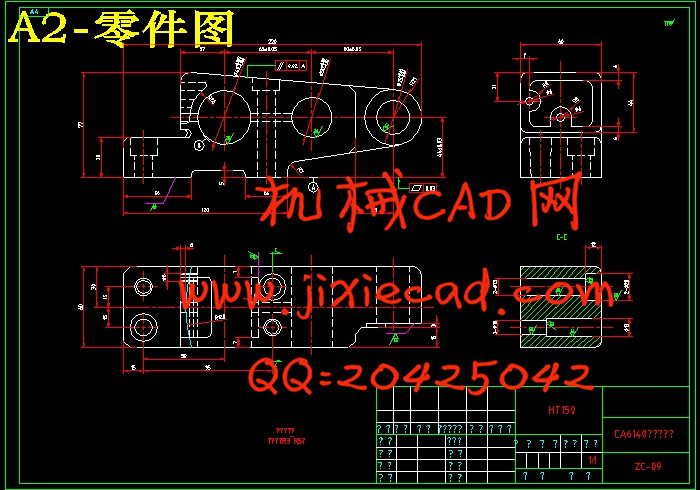

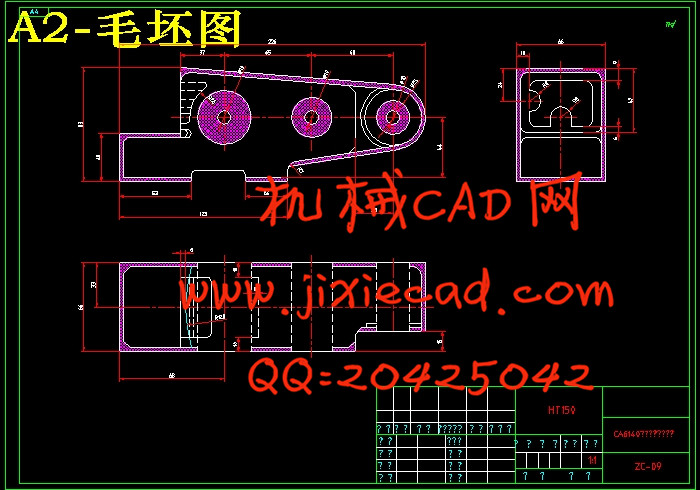

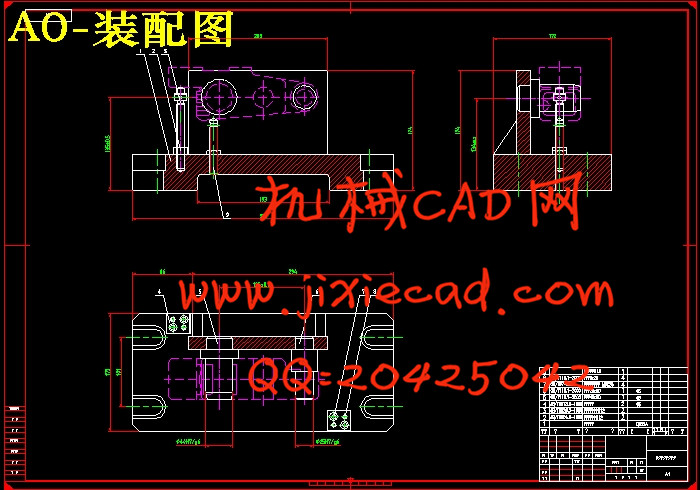

本篇设计是基于ca6140车床后托架零件的加工工艺规程和关于铣底面的专用夹具设计。ca6140车床后托架零件的主要加工表面是下底面及文章的重点在于对ca6140车床后托架的工艺性和力学性能分析,对加工工艺进行合理分析,选择确定合理的毛坯、加工方式、高效设计、省力的夹具,经过实践证明,最终加工出合格的ca6140车床后托架零件。

关键词:ca6140车床后托架类零件;工艺;夹具

Abstract

This design is based on the CA6140 lathe after the bracket parts of the processing procedures and the design of the special fixture on the bottom surface. The main processing surface of the rear bracket parts of the CA6140 lathe is the bottom surface and the machining of the hole. Generally speaking, the machining accuracy of the plane is guaranteed to ensure the machining accuracy of the plane is relatively easy compared with the machining precision of the hole. Aperture processing is the use of special drilling jig or boring jig, the general use of the clamping method of flexible clamping, clamping reliable. The bottom surface of the design and processing of the design choice of milling fixture, the milling fixture positioning reliable, so the production efficiency is high, can meet the design requirements.

The focus of the article is analysis of bracket, the processing and mechanical properties of CA6140 lathe, the processing technology of rational analysis, to determine the reasonable blank, processing, efficient design, labor saving fixture. Through practice proved that ultimately produce a qualified CA6140 lathe bracket parts.

Key words: The CA6140 lathe after the bracket;Milling fixture; Boring jig

ca6140机床后托架机械加工工艺及铣底面夹具设计

目录

第一章 绪论 1

第二章 加工工艺规程设计 1

2.1 零件的分析 1

2.1.1 零件的作用 2

2.1.2 零件的工艺分析 3

2.2 ca6140车床后托架的加工顺序和加工方案的选择 5

2.2.1 孔和平面的加工顺序 6

2.2.2 加工方案选择 7

2.3 ca6140车床后托架加工定位基准的选择 8

2.3.1 粗基准的选择 11

2.3.2 精基准的选择 12

2.4 ca6140车床后托架加工主要工序安排 13

2.5 机械加工余量、工序尺寸及毛坯尺寸的确定 14

2.6 选择加工设备及刀、量具 15

2.7 确定切削用量及基本工时(机动时间) 16

第三章 时间定额计算及生产安排 17

第四章 ca6140车床后托架钻孔夹具设计 18

4.1 设计要求 20

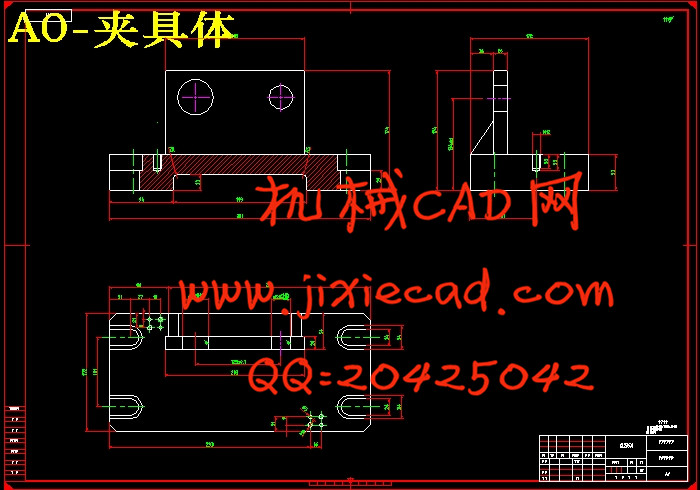

4.2 夹具设计 21

4.2.1 定位基准的选择 22

4.2.2 切削力及夹紧力的计算 24

4.3 定位误差的分析 26

4.4 夹具设计及操作的简要说明 27

结 论 28

参考文献 29

致 谢 30