设计简介

摘要

在现代生产中,机床夹具作为机床的一部分已成为机械加工中不可缺少的工艺装备。在工件生产批量较大时,除了考虑工件加工精度外我们还需要考虑到生产率和经济性问题,所以常常采用专门为某一零件的某一工序而设计的专用夹具进行工件的装夹。这时不需划线和找正,只需将工件放到夹具中,即可确定工件与机床及刀具之间的位置,并将工件夹紧。专用夹具是针对某一工件的某一工序的加工要求而专门设计和制造的夹具。其特点是针对性极强,没有通用性。在产品相对稳定、批量较大的生产中,常用各种专用夹具,可获得较高的生产率和加工精度。

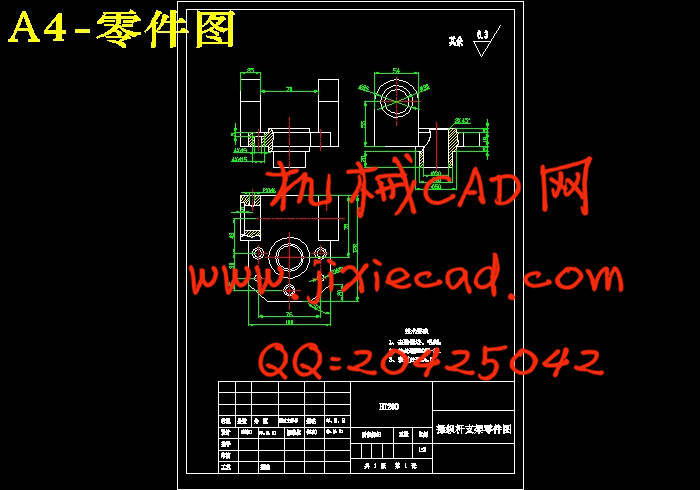

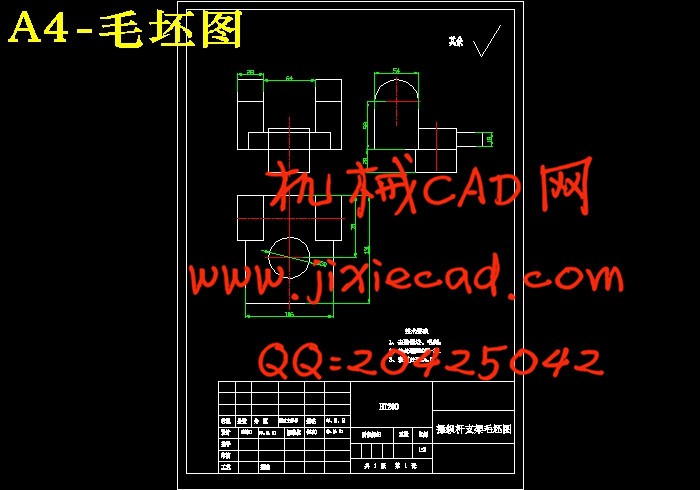

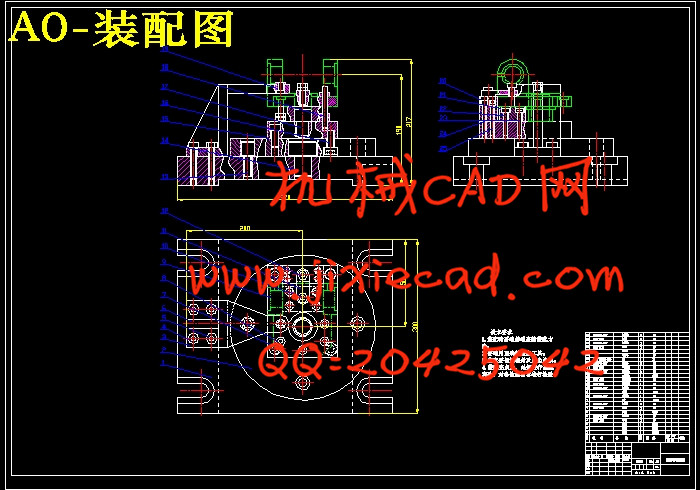

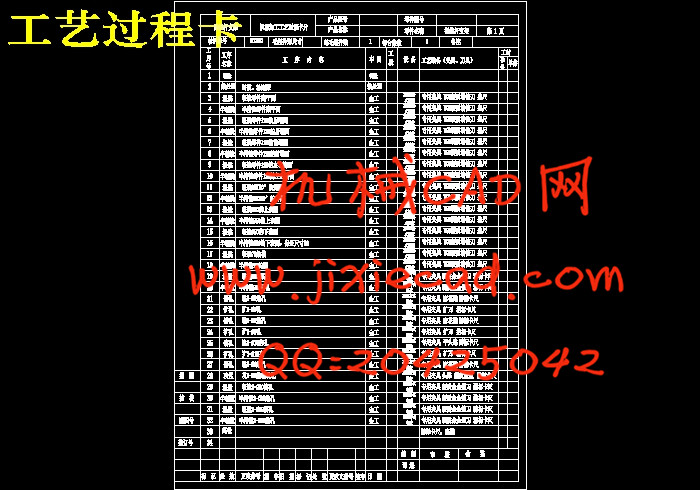

本设计给定的设计零件是操纵杆支架,它的主要作用是固定操纵杆,使其在行驶过程中牢固可靠。零件上的3-Φ15孔用螺栓固定在底座上,操纵杆用Φ30的定位销固定在支架上,并且在换挡时依靠利用70槽轨迹不会引起偏差。在充分分析零件的基础上,确定加工各工序的基准,编制出了加工工艺过程卡、加工工序卡,绘制装配图及主要零件图。本次设计共设计出了2套夹具加工工件,设计合理,操作简便,为零件的加工提供钱有力的保障。

关键词:机床夹具、专用夹具、操纵杆支架、基准、加工工艺过程、加工工序

ABSTRACT

In modern production, jigs and fixtures, as part of the machining tool has become an indispensable technology and equipment. Workpiece production volume is large, in addition to considering the accuracy of the workpiece outside, we also need to take into account productivity and economic issues, so often using special fixtures designed specifically for a particular part of a process designed to make clamping workpieces. Then without scoring and alignment, simply place the workpiece fixture, you can determine the position of the workpiece and the cutting tool and the machine between the clamp and the workpiece.Special fixture for a workpiece machining process requires a specially designed and manufactured fixtures. Its characteristics are highly targeted, no versatility. The product is relatively stable, large-volume production, the common variety of special fixtures, obtain higher productivity and precision.

The design of a given design parts joystick support, its main role is fixed joystick, making it solid and reliable in the process of moving. 3-Φ15 bolt holes on the part fixed to the base, with Φ30 lever positioning pins fixed to the bracket, and rely on the use of the track grooves 70 without causing deviation by the shift. In the full analysis of the parts based on the benchmarking process each step, the preparation of the machining process card, card manufacturing processes, assembly drawing and major parts diagram. The design of the two sets were designed clamp the workpiece, reasonable design, easy to operate, provide strong protection money for machined parts.

Keywords: jigs, special fixtures, joystick support, benchmarks, machining process, manufacturing processes

目 录

摘要 I

ABSTRACT II

第1章 绪论 1

1.1 机床夹具的功能和作用 1

1.1.1 机床夹具的功能 1

1.1.2 机床夹具的作用 1

1.2 机床夹具的组成 2

1.3 机床夹具的分类及设计要求 3

1.3.1 机床夹具的分类 3

1.3.2 机床夹具的设计要求 4

1.4 机床夹具的现状及发展方向 4

1.5 课题设计的价值 5

第2章 操纵杆支架机械加工工艺规程设计 7

2.1 零件的工艺分析及生产类型的确定 7

2.1.1 零件的作用 7

2.1.2 零件的工艺性能 7

2.1.3 零件的加工表面分析 8

2.1.4 零件生产类型的确定 8

2.2 零件工艺规程设计 8

2.2.1 零件制造形式的确定 8

2.2.2 基准的选择 9

2.3 制定加工工艺路线 10

2.4 选择加工设备及刀具、夹具、量具 11

2.5 机械加工余量,工序尺寸及毛坯尺寸的确定 11

2.6 确定切削用量及基本工时 13

第3章 专用夹具的设计 19

3.1 问题的提出 19

3.2 夹具的设计要求 19

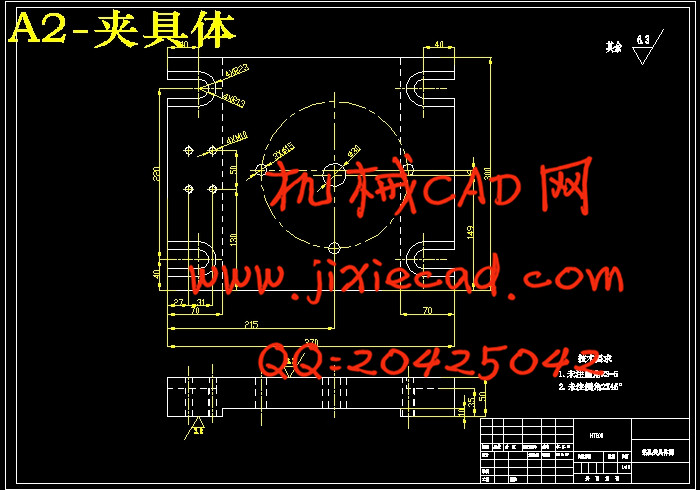

3.3 钻3-Ф9孔的钻床夹具设计 19

3.3.1 定位方案的确定 19

3.3.2 定位元件的确定 20

3.3.3 夹紧装置的确定 21

3.3.4 夹具体的确定 21

3.3.5 钻削力的确定 22

3.2.6 定位误差分析 22

第4章 结论 23

参考文献 24