设计简介

摘 要

本次设计的主要内容是操纵杆支架加工工艺及夹具设计,操纵杆支架主要是与其它零件配对使用,其主要加工表面及控制位置为本文的研究重点在于通过对操纵杆支架的工艺性和力学性能分析,对加工工艺进行合理分析,选择确定合理的毛坯、加工方式、设计高效、省力的夹具,通过实践验证,最终加工出合格的操纵杆支架零件。

关键词:操纵杆支架;加工余量;工艺;夹具ABSTRACT

Enable producing the target in process of production raw materials, the blank , state of quality and quantity on part become always take place direct course of change ask craft course, if the blank is made, machining, heat treatment , assemble etc. and call it the craft course. In the course of making the craft , is it confirm every erector location and worker step that process need this of process to want, the locomotive of processing , this process , and the entering the giving amount of the lathe, cut depth , the rotational speed of the main shaft and speed of cutting, the jig of this process, the cutter and measuring tool, a one hundred sheets of number of times still leaves and a one hundred sheets of length leaves, calculate basic time of this process , auxiliary time and service time of place of working finally.

At present, part of the processing of domestic have begun to close to the machine tool, but also need to clamp the workpiece, that is to say, although the technology has been greatly improved but his nature has not changed much, on the flip side, because of his skill and precision is high, so a high quality tool holder of machine tools is an absolute necessity. As everyone knows, because our technology in the unceasing development, technical requirements for processing of the knife is also more and more high, before an ordinary lathe is clamped four tool, and now there is a large number of will not meet the work requirements, therefore, tool holder part can clamp the tool also needs our staff to develop.

KEYWORDS:fixture multi-function; Die forging links; Group technology;clipping tight

目录

摘要 IAt present, part of the processing of domestic have begun to close to the machine tool, but also need to clamp the workpiece, that is to say, although the technology has been greatly improved but his nature has not changed much, on the flip side, because of his skill and precision is high, so a high quality tool holder of machine tools is an absolute necessity. As everyone knows, because our technology in the unceasing development, technical requirements for processing of the knife is also more and more high, before an ordinary lathe is clamped four tool, and now there is a large number of will not meet the work requirements, therefore, tool holder part can clamp the tool also needs our staff to develop.

KEYWORDS:fixture multi-function; Die forging links; Group technology;clipping tight

目录

ABSTRACT II

第一章 绪论 1

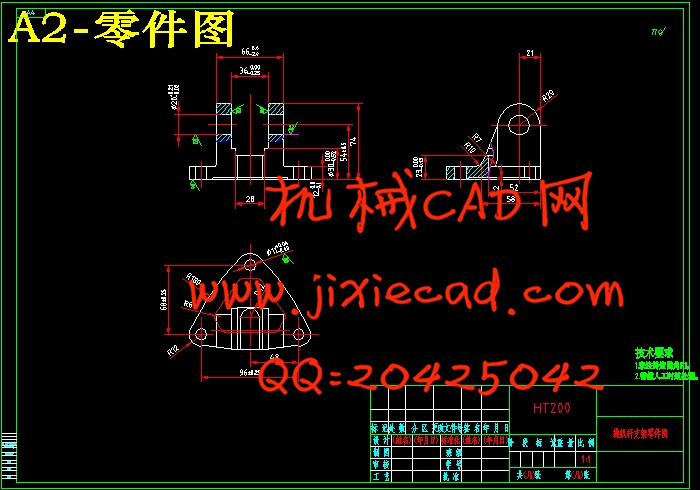

第二章 零件的分析 5

2.1零件的作用 5

2.2零件的工艺分析 5

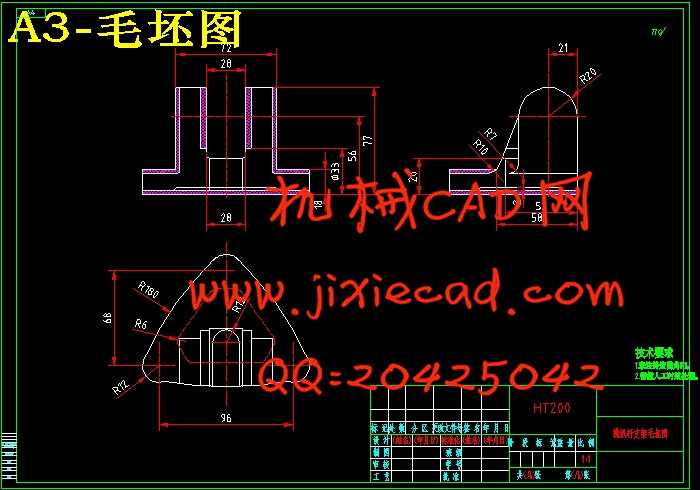

第三章 确定毛坯,绘制毛坯图、零件图 8

3.1确定毛坯的制造形式及材料 8

3.2机械加工余量、工序尺寸及毛坯尺寸的确定 8

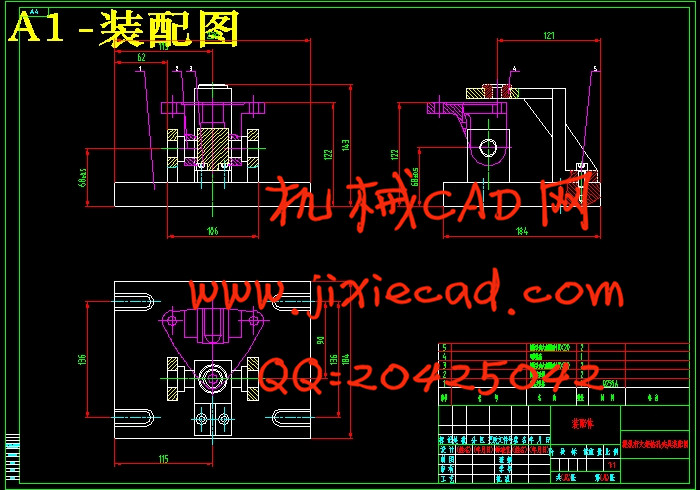

第四章 工艺规程设计 10

4.1定位基准的选择 10

4.2制定工艺路线 10

4.3选择加工设备及刀、夹、量具 14

4.4 确定切削用量及基本工时 16

4.4.1粗、精铣底部端面 17

4.4.2粗、精铣

4.4.3粗铣

4.4.4精铣

4.4.5粗铣

4.4.6精铣

4.4.7粗铣

4.4.8钻、绞

4.4.9 钻、绞

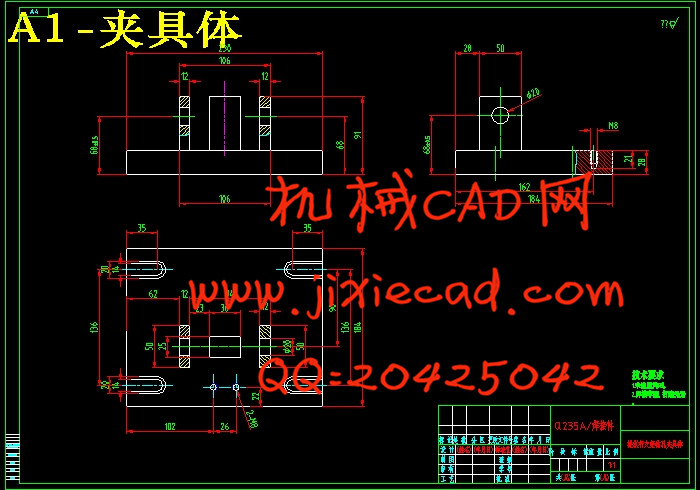

第五章 钻孔夹具设计 26

5.1定位基准的选择 26

5.2定位元件的设计 26

5.3切削力及夹紧力的计算 27

5.4钻套的设计 28

5.5夹紧装置的设计 29

小 结 28

致 谢 29

参考文献 30