设计简介

摘 要

此次课程设计是学习完《机械制造技术基础》这一门课程后的一次实践学习。所以,他最突出的特点是很强的实践性。在设计过程中,主要完成了某零件的工艺卡片与工序卡片的制定,进一步熟悉了机械生产的全过程;同时针对某一指定工序设计夹具体,实现零件的大批量生产。

此次课程设计的主要意义有:

一. 进一步熟悉所学课程,并应用到实践,再从实践中反过来加强对所学知识的熟悉程度。

二. 增强知识的综合运用的能力。此次课程设计,不但设计到《机械制造技术基础》这一门课程,更是对《机械精度设计与检测》、《机械图学》与《机械设计》等课程的一次全面复习,与综合运用能力的锻炼。

三. 增强自主解决问题的能力与设计能力。

Abstract

The curriculum design is another learning after the learning of "Manufacturing Technology" course this time. Therefore, his most prominent feature is the strong practicalism. We have completed the main parts of the process of a card and the process of a development of the card, becoming more familiar with the machinery of the entire process of production; At the same time for a specific folder we design processes and achieve high-volume production parts.

The main significance of the curriculum design has the followings:

First. To further familiarize themselves with the course, and applied to practice, from practice, in turn, enhance the knowledge of the degree of familiarity with

Second. The curriculum design is not only a totally review of the such courses as "Machinery Manufacturing Technology"、"precision mechanical design and testing"、

"mechanical Graphics" and "mechanical design",but also a exercise comprehensive use of ability.

Third. Enhance the ability of independent problem-solving and design capability

1.2左摆动杠杆的技术要求 1

1.3左摆动杠杆的工艺分析 2

1.4确定生产类型 3

2确定毛坯、绘制毛坯简图 3

2.1选择毛坯 3

2.2确定毛坯的尺寸公差和机械加工余量 3

3拟定左摆动杠杆工艺路线 5

3.1定位基准的选择 5

3.2表面加工方法的确定 5

3.3加工阶段的划分 6

3.4工序的集中与分散 6

3.5工序顺序的安排 6

3.6确定工艺路线 7

5.1切削用量的计算 9

5.2时间定额的计算 10

6机床的夹具设计 12

6.1定位方案设计 12

6.2导向装置设计 12

6.3夹紧装置设计 13

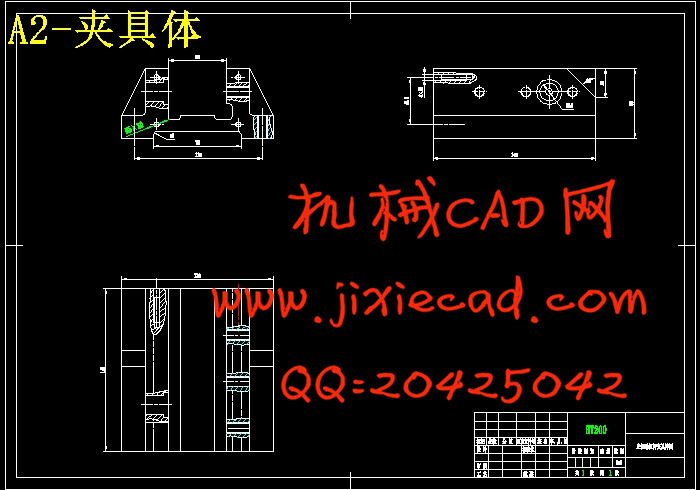

6.4夹具体设计 13

7方案综合评价与分析 13

8体会与展望 13

此次课程设计是学习完《机械制造技术基础》这一门课程后的一次实践学习。所以,他最突出的特点是很强的实践性。在设计过程中,主要完成了某零件的工艺卡片与工序卡片的制定,进一步熟悉了机械生产的全过程;同时针对某一指定工序设计夹具体,实现零件的大批量生产。

此次课程设计的主要意义有:

一. 进一步熟悉所学课程,并应用到实践,再从实践中反过来加强对所学知识的熟悉程度。

二. 增强知识的综合运用的能力。此次课程设计,不但设计到《机械制造技术基础》这一门课程,更是对《机械精度设计与检测》、《机械图学》与《机械设计》等课程的一次全面复习,与综合运用能力的锻炼。

三. 增强自主解决问题的能力与设计能力。

Abstract

The curriculum design is another learning after the learning of "Manufacturing Technology" course this time. Therefore, his most prominent feature is the strong practicalism. We have completed the main parts of the process of a card and the process of a development of the card, becoming more familiar with the machinery of the entire process of production; At the same time for a specific folder we design processes and achieve high-volume production parts.

The main significance of the curriculum design has the followings:

First. To further familiarize themselves with the course, and applied to practice, from practice, in turn, enhance the knowledge of the degree of familiarity with

Second. The curriculum design is not only a totally review of the such courses as "Machinery Manufacturing Technology"、"precision mechanical design and testing"、

"mechanical Graphics" and "mechanical design",but also a exercise comprehensive use of ability.

Third. Enhance the ability of independent problem-solving and design capability

目录

1左摆动杠杆的工艺分析

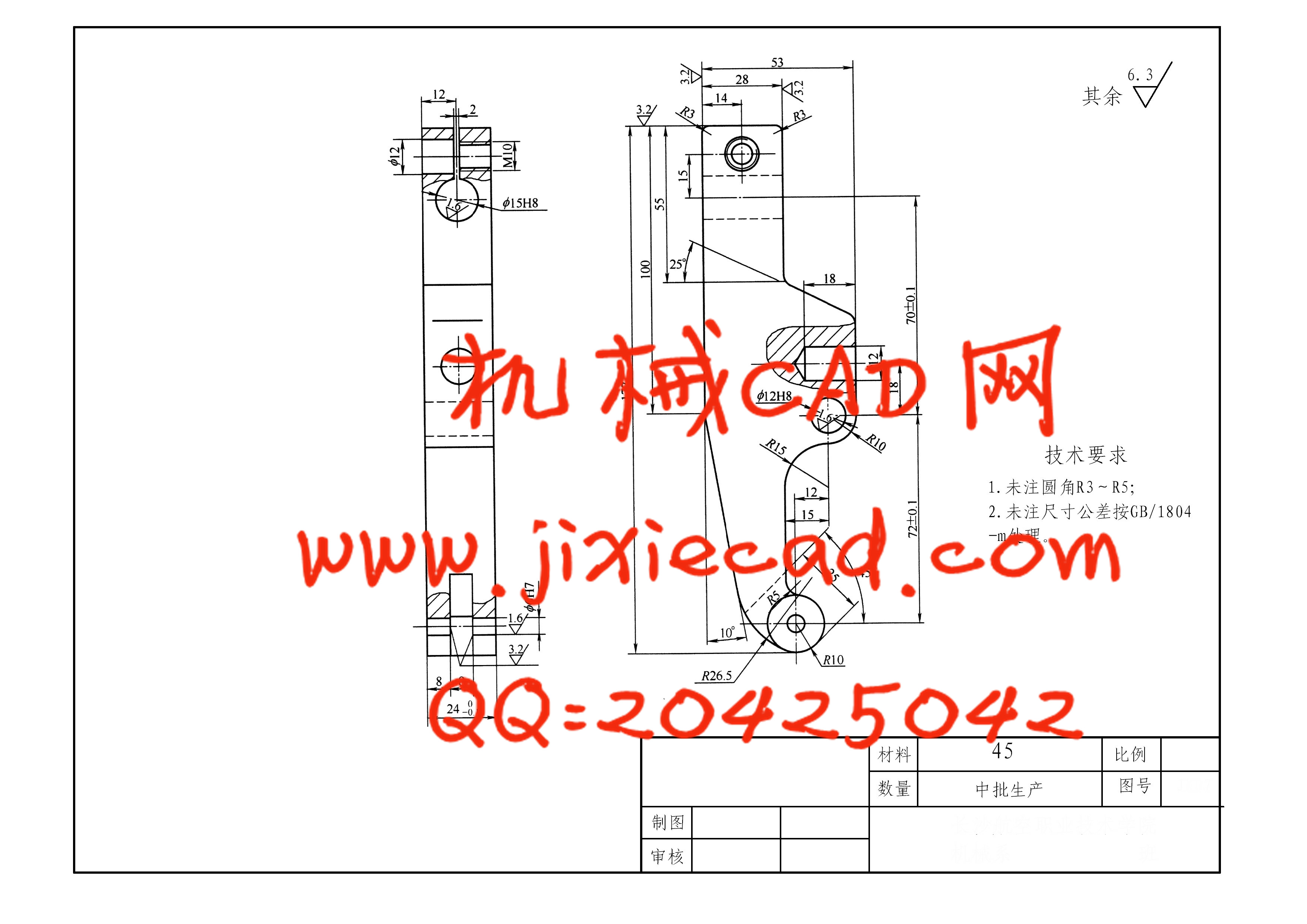

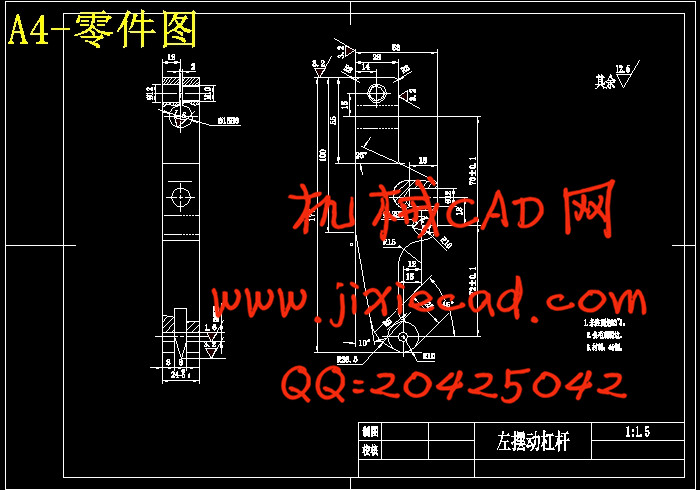

1.1左摆动杠杆的用途 11.2左摆动杠杆的技术要求 1

1.3左摆动杠杆的工艺分析 2

1.4确定生产类型 3

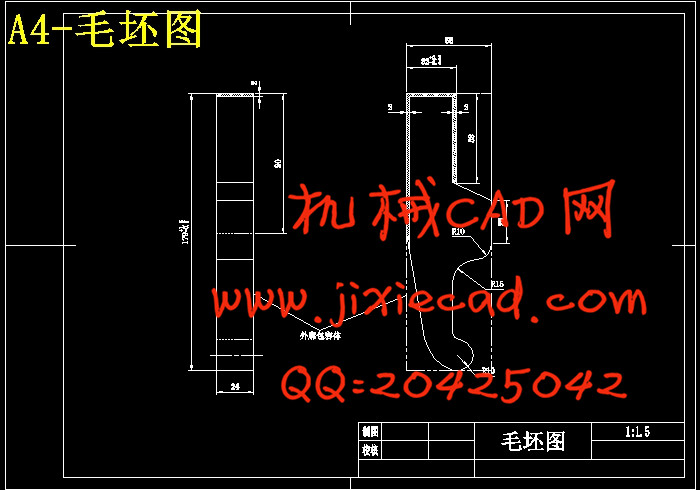

2确定毛坯、绘制毛坯简图 3

2.1选择毛坯 3

2.2确定毛坯的尺寸公差和机械加工余量 3

3拟定左摆动杠杆工艺路线 5

3.1定位基准的选择 5

3.2表面加工方法的确定 5

3.3加工阶段的划分 6

3.4工序的集中与分散 6

3.5工序顺序的安排 6

3.6确定工艺路线 7

5.1切削用量的计算 9

5.2时间定额的计算 10

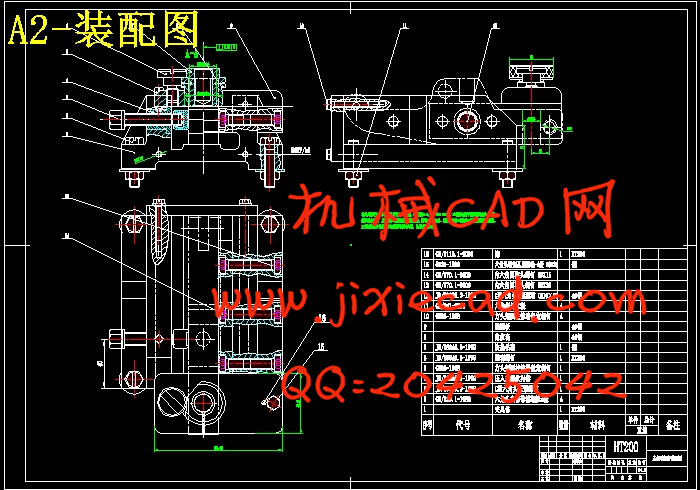

6机床的夹具设计 12

6.1定位方案设计 12

6.2导向装置设计 12

6.3夹紧装置设计 13

6.4夹具体设计 13

7方案综合评价与分析 13

8体会与展望 13