设计简介

摘 要

随着机械制造技术不断发展,各制造商推出各种各样的先进的汽车零部件制造技术,换挡叉裂解技术就是20世纪90年代出现的一种先进的换挡叉加工新技术,和传统加工技术相比,该技术具有大幅度提高产品质量﹑提高生产率﹑降低生产成本等突出优点而备受业界关注。我们国家正在不断地改变换挡叉的传统加工方法,加快提高换挡叉的加工水平,不断缩小同先进汽车生产国家的差距,使生产厂与世界先进换挡叉生产水平的差距越来越小,不断加强了我国汽车整体的生产水平。

机械制造工艺学课程设计使我们学完了大学的全部基础课技术基础课以及大部分专业课之后进行的,这是我们在进行毕业设计之前对所学的各课程的一次深入的综合性的总复习,也是一次理论联系实际的训练,因此,它在我们四年的大学生活中占有重要的地位。

Abstract

The manufactory continuously releases the forerunner’s car of various cash kind zero parts manufacturing technique, stir the fork crack solution technique is the stir of a kind of forerunner fork which appears in 90’s for 20 centuries to process a new technique, compared with the traditional processing technology, that technique have significant product quality, raise rate of production and lower production cost etc.

We are just national at constantly the change stir fork of tradition process a method, speed an exaltation to stir process of fork level, continuously contract a together advanced car to produce a national margin, for example one an important position in we the university of the level more and more small, continuously strengthened our country the car whole production level

The machine manufacturing craft learns a course design to make us to carry on after finishing learn all foundation lessons, lesson and part of professional lessons of the technique foundation of university. This is that we are before carry on graduation design to once go deep into of each course learn of synthetic always review, is also an ories to contact actual training, therefore, it occupies an important position in we the university of four years the life.

目 录

四、进度安排... I

五、指导教师评语... I

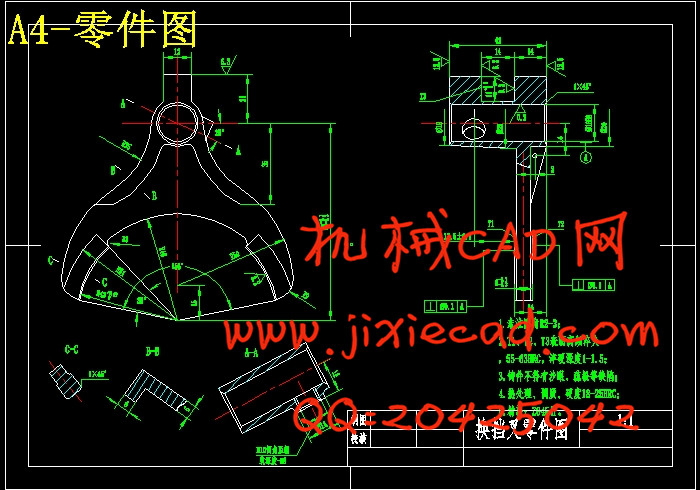

1零件工艺性分析... 1

1.1换挡叉的概述... 1

1.2换挡叉的技术要求... 1

1.3分析换挡叉的工艺性... 2

1.4确定换挡叉的工艺类型... 2

2换挡叉机械加工工艺规程设计... 2

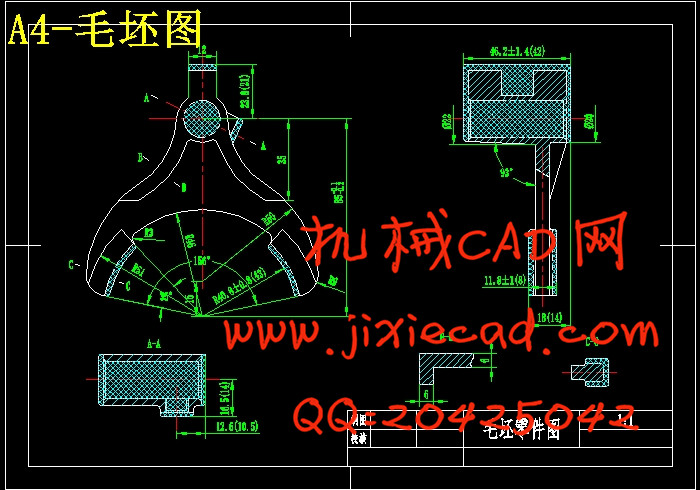

2.1换挡叉材料及毛坯制造方法... 2

2.2确定毛坯尺寸公差和加工余量... 3

2.3定位基准的选择... 3

2.4制订工艺路线... 4

2.5确定切削用量及基本工时... 6

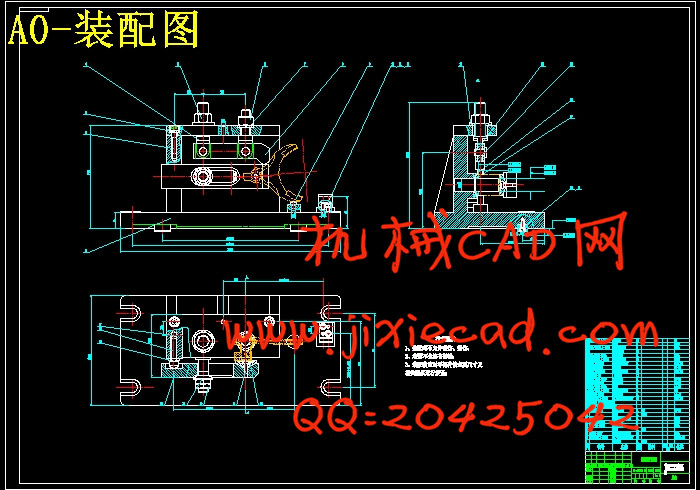

3 铣叉脚2面距离8mm夹具设计... 10

4体会与展望... 14

5参考文献... 14

随着机械制造技术不断发展,各制造商推出各种各样的先进的汽车零部件制造技术,换挡叉裂解技术就是20世纪90年代出现的一种先进的换挡叉加工新技术,和传统加工技术相比,该技术具有大幅度提高产品质量﹑提高生产率﹑降低生产成本等突出优点而备受业界关注。我们国家正在不断地改变换挡叉的传统加工方法,加快提高换挡叉的加工水平,不断缩小同先进汽车生产国家的差距,使生产厂与世界先进换挡叉生产水平的差距越来越小,不断加强了我国汽车整体的生产水平。

机械制造工艺学课程设计使我们学完了大学的全部基础课技术基础课以及大部分专业课之后进行的,这是我们在进行毕业设计之前对所学的各课程的一次深入的综合性的总复习,也是一次理论联系实际的训练,因此,它在我们四年的大学生活中占有重要的地位。

Abstract

The manufactory continuously releases the forerunner’s car of various cash kind zero parts manufacturing technique, stir the fork crack solution technique is the stir of a kind of forerunner fork which appears in 90’s for 20 centuries to process a new technique, compared with the traditional processing technology, that technique have significant product quality, raise rate of production and lower production cost etc.

We are just national at constantly the change stir fork of tradition process a method, speed an exaltation to stir process of fork level, continuously contract a together advanced car to produce a national margin, for example one an important position in we the university of the level more and more small, continuously strengthened our country the car whole production level

The machine manufacturing craft learns a course design to make us to carry on after finishing learn all foundation lessons, lesson and part of professional lessons of the technique foundation of university. This is that we are before carry on graduation design to once go deep into of each course learn of synthetic always review, is also an ories to contact actual training, therefore, it occupies an important position in we the university of four years the life.

目 录

四、进度安排... I

五、指导教师评语... I

1零件工艺性分析... 1

1.1换挡叉的概述... 1

1.2换挡叉的技术要求... 1

1.3分析换挡叉的工艺性... 2

1.4确定换挡叉的工艺类型... 2

2换挡叉机械加工工艺规程设计... 2

2.1换挡叉材料及毛坯制造方法... 2

2.2确定毛坯尺寸公差和加工余量... 3

2.3定位基准的选择... 3

2.4制订工艺路线... 4

2.5确定切削用量及基本工时... 6

3 铣叉脚2面距离8mm夹具设计... 10

4体会与展望... 14

5参考文献... 14