设计简介

摘要

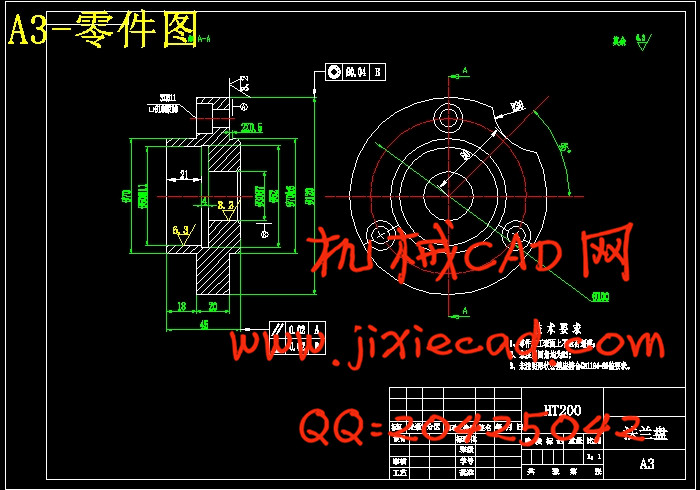

本设计是基于法兰盘零件的加工工艺规程及一些工序的专用夹具设计。法兰盘零件的主要加工表面是外圆及孔系。一般来说,保证平面的加工精度要比保证孔系的加工精度容易。因此,本设计遵循先面后槽的原则。并将孔与平面的加工明确划分成粗加工和精加工阶段以保证孔系加工精度。主要加工工序安排是先以支承孔系定位加工出顶平面,在后续工序中除个别工序外均用顶平面和工艺孔定位加工其他孔系与平面。夹具选用专用夹具,夹紧方式多选用手动夹紧,夹紧可靠,机构可以不必自锁。因此生产效率较高。适用于大批量、流水线上加工。能够满足设计要求。

关键词 法兰盘类零件,加工工艺,专用夹具,设计

目 录

1 加工工艺规程设计···················································································· 4

1.1 零件的分析·············································································································· 4

1.1.1 零件的作用······································································································· 4

1.1.2 零件的工艺分析································································································ 4

1.2 法兰盘加工的主要问题和工艺过程设计所应采取的相应措施···································· 5

1.3 法兰盘加工定位基准的选择····················································································· 5

1.3.1 粗基准的选择···································································································· 5

1.3.2 精基准的选择···································································································· 5

1.4 法兰盘加工主要工序安排························································································· 5

1.5 机械加工余量、工序尺寸及毛坯尺寸的确定····························································· 8

1.6选择加工设备及刀、量具·························································································· 8

1.7确定切削用量及基本工时(机动时间)····································································· 8

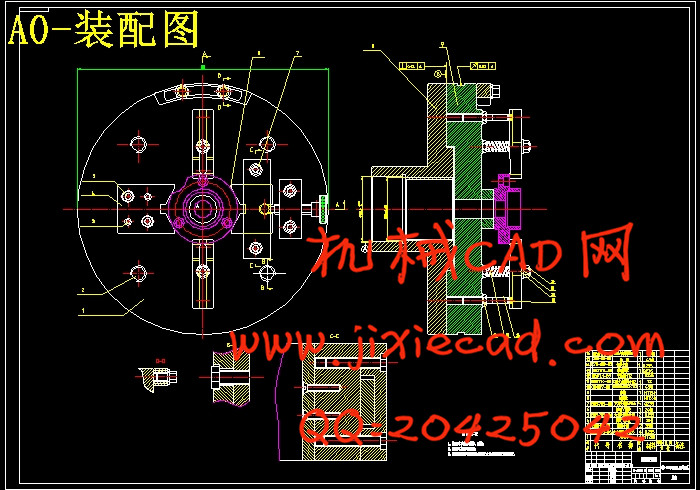

第2章 加工Φ60H11内孔孔夹具设计························································· 21

2.1 车床夹具设计要求说明······························································································ 21

2.2车床夹具的设计要点·································································································· 22

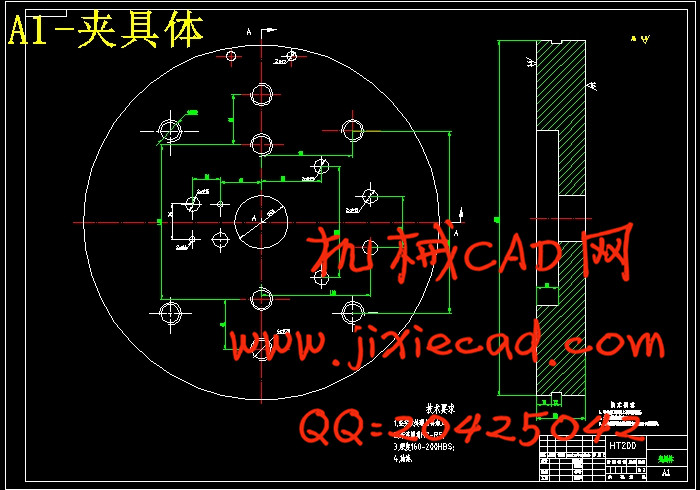

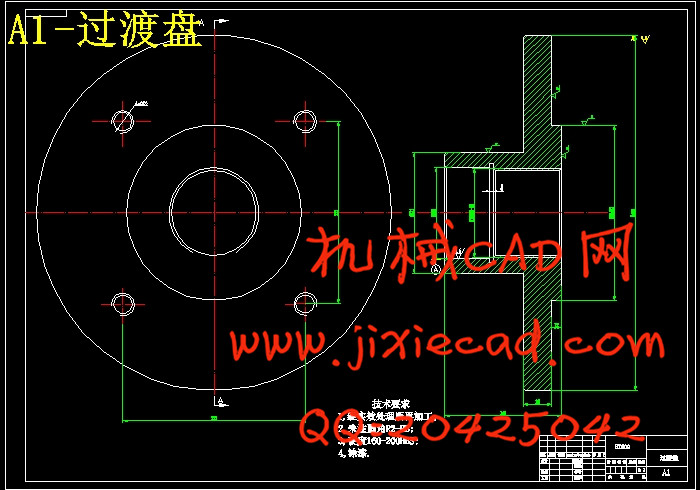

2.3 定位机构·················································································································· 23

2.4夹紧机构·················································································································· 24

2.5零件的车床夹具的加工误差分析·················································································· 25

2.6 确定夹具体结构尺寸和总体结构·················································································· 26

2.6 零件的车床专用夹具简单使用说明·············································································· 27

结 论··········································································································· 28

参考文献····································································································· 29

致 谢····································································································· 31

本设计是基于法兰盘零件的加工工艺规程及一些工序的专用夹具设计。法兰盘零件的主要加工表面是外圆及孔系。一般来说,保证平面的加工精度要比保证孔系的加工精度容易。因此,本设计遵循先面后槽的原则。并将孔与平面的加工明确划分成粗加工和精加工阶段以保证孔系加工精度。主要加工工序安排是先以支承孔系定位加工出顶平面,在后续工序中除个别工序外均用顶平面和工艺孔定位加工其他孔系与平面。夹具选用专用夹具,夹紧方式多选用手动夹紧,夹紧可靠,机构可以不必自锁。因此生产效率较高。适用于大批量、流水线上加工。能够满足设计要求。

关键词 法兰盘类零件,加工工艺,专用夹具,设计

目 录

1 加工工艺规程设计···················································································· 4

1.1 零件的分析·············································································································· 4

1.1.1 零件的作用······································································································· 4

1.1.2 零件的工艺分析································································································ 4

1.2 法兰盘加工的主要问题和工艺过程设计所应采取的相应措施···································· 5

1.3 法兰盘加工定位基准的选择····················································································· 5

1.3.1 粗基准的选择···································································································· 5

1.3.2 精基准的选择···································································································· 5

1.4 法兰盘加工主要工序安排························································································· 5

1.5 机械加工余量、工序尺寸及毛坯尺寸的确定····························································· 8

1.6选择加工设备及刀、量具·························································································· 8

1.7确定切削用量及基本工时(机动时间)····································································· 8

第2章 加工Φ60H11内孔孔夹具设计························································· 21

2.1 车床夹具设计要求说明······························································································ 21

2.2车床夹具的设计要点·································································································· 22

2.3 定位机构·················································································································· 23

2.4夹紧机构·················································································································· 24

2.5零件的车床夹具的加工误差分析·················································································· 25

2.6 确定夹具体结构尺寸和总体结构·················································································· 26

2.6 零件的车床专用夹具简单使用说明·············································································· 27

结 论··········································································································· 28

参考文献····································································································· 29

致 谢····································································································· 31