设计简介

摘 要

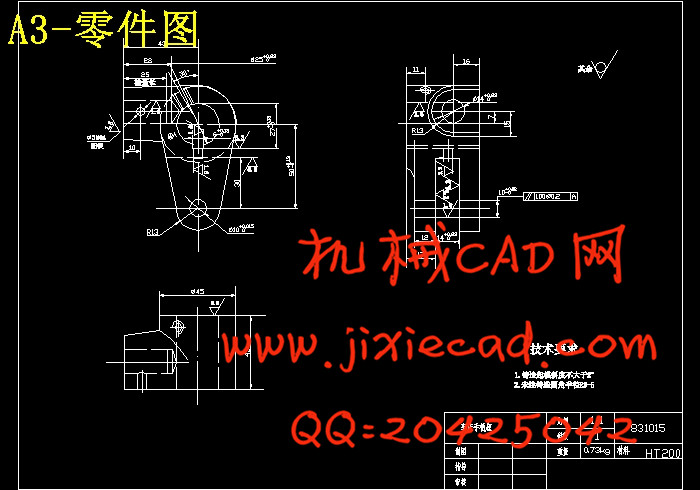

本设计是基于手柄座零件的加工工艺规程及一些工序的专用夹具设计。手柄座零件的主要加工表面是平面及孔系。一般来说,保证平面的加工精度要比保证孔系的加工精度容易。因此,本设计遵循先面后孔的原则。并将孔与平面的加工明确划分成粗加工和精加工阶段以保证孔系加工精度。基准选择以手柄座的孔作为粗基准,以结合面与两个工艺孔作为精基准。主要加工工序安排是系定位加工出工艺孔。在后续工序中除个别工序外均用顶平面和工艺孔定位加工其他孔系与平面。夹具选用专用夹具,夹紧方式多选用液压夹紧,夹紧可靠,机构可以不必自锁。因此生产效率较高。适用于大批量、流水线上加工。能够满足设计要求。

关键词:手柄座类零件;工艺;夹具;

ABSTRACT

The design of special fixture processing procedures handle seat parts and process design based on. The main processing surface of the handle seat is the plane and a series of hole. In general, to ensure the processing accuracy of plane than to guarantee the machining accuracy of the series of hole. Therefore, the design follows the principle of the surface after the first hole. And the hole and the plane processing clearly divided into rough machining stage and finish machining stage in order to guarantee the working accuracy of the series of hole. The basis choice to handle seat hole as a rough benchmark, to combine with two holes as a precision technology base. The main processing arrangement is positioning processing out of holes. In the follow-up working procedure all working procedures except several special ones by using the top plane and hole positioning processing other series of hole and plane. Choose special fixture fixture, clamping means more choice of hydraulic clamping, clamping reliable, agencies can not self-locking. Therefore the production efficiency is higher. Suitable for large batch processing, assembly line. To meet the design requirements.

Keywords: handle seat parts; technology; fixture;

目 录

摘 要·········································································································· II

ABSTRACT·································································································· III

第1章 绪论··································································································· 1

1.1 机械加工工艺概述··········································································· 1

1.2机械加工工艺流程············································································ 1

1.3夹具概述························································································· 2

1.4机床夹具的功能··············································································· 3

1.5机床夹具的发展趋势········································································· 3

1.5.1机床夹具的现状·········································································· 3

1.5.2现代机床夹具的发展方向····························································· 4

第2章 加工工艺规程设计················································································ 5

2.1 零件的分析····················································································· 5

2.1.1 零件的作用··············································································· 5

2.1.2 零件的工艺分析········································································· 5

2.2 手柄座加工的主要问题和工艺过程设计所应采取的相应措施·················· 6

2.2.1 孔和平面的加工顺序··································································· 6

2.2.2加工方案选择············································································· 7

2.3 手柄座加工定位基准的选择······························································· 7

2.3.1 粗基准的选择············································································ 7

2.3.2 精基准的选择············································································ 7

2.4 手柄座加工主要工序安排·································································· 8

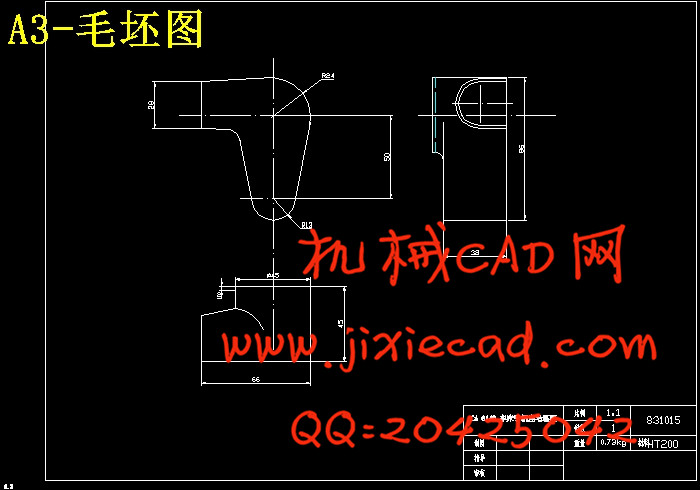

2.5 机械加工余量、工序尺寸及毛坯尺寸的确定······································· 10

2.6确定切削用量及基本工时(机动时间)·············································· 11

2.7 时间定额计算及生产安排································································ 19

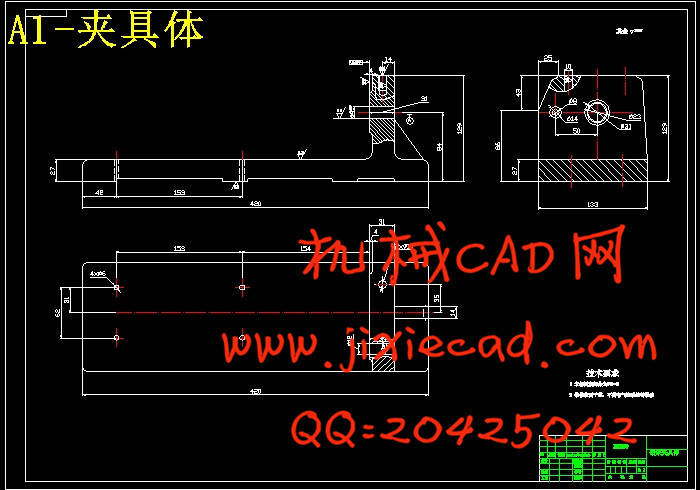

第3章 铣14槽夹具设计················································································ 21

3.1设计要求······················································································· 21

3.2夹具设计······················································································· 21

3.2.1 定位基准的选择······································································ 21

3.2.2 切削力及夹紧力的计算···························································· 21

3.3定位误差的分析·············································································· 23

3.4 确定夹具体结构和总体结构····························································· 24

3.5夹具设计及操作的简要说明······························································ 25

第4章 钻¢14孔夹具设计············································································ 27

4.1设计要求······················································································· 27

4.2夹具设计······················································································· 30

4.2.1 定位基准的选择······································································ 30

4.2.2 切削力及夹紧力的计算···························································· 30

4.3定位误差的分析·············································································· 34

4.4 钻套、衬套、钻模板设计与选用······················································· 34

4.5 确定夹具体结构和总体结构····························································· 36

4.6夹具设计及操作的简要说明······························································ 37

总 结········································································································ 38

致 谢········································································································ 39

参 考 文 献································································································· 41

本设计是基于手柄座零件的加工工艺规程及一些工序的专用夹具设计。手柄座零件的主要加工表面是平面及孔系。一般来说,保证平面的加工精度要比保证孔系的加工精度容易。因此,本设计遵循先面后孔的原则。并将孔与平面的加工明确划分成粗加工和精加工阶段以保证孔系加工精度。基准选择以手柄座的孔作为粗基准,以结合面与两个工艺孔作为精基准。主要加工工序安排是系定位加工出工艺孔。在后续工序中除个别工序外均用顶平面和工艺孔定位加工其他孔系与平面。夹具选用专用夹具,夹紧方式多选用液压夹紧,夹紧可靠,机构可以不必自锁。因此生产效率较高。适用于大批量、流水线上加工。能够满足设计要求。

关键词:手柄座类零件;工艺;夹具;

ABSTRACT

The design of special fixture processing procedures handle seat parts and process design based on. The main processing surface of the handle seat is the plane and a series of hole. In general, to ensure the processing accuracy of plane than to guarantee the machining accuracy of the series of hole. Therefore, the design follows the principle of the surface after the first hole. And the hole and the plane processing clearly divided into rough machining stage and finish machining stage in order to guarantee the working accuracy of the series of hole. The basis choice to handle seat hole as a rough benchmark, to combine with two holes as a precision technology base. The main processing arrangement is positioning processing out of holes. In the follow-up working procedure all working procedures except several special ones by using the top plane and hole positioning processing other series of hole and plane. Choose special fixture fixture, clamping means more choice of hydraulic clamping, clamping reliable, agencies can not self-locking. Therefore the production efficiency is higher. Suitable for large batch processing, assembly line. To meet the design requirements.

Keywords: handle seat parts; technology; fixture;

目 录

摘 要·········································································································· II

ABSTRACT·································································································· III

第1章 绪论··································································································· 1

1.1 机械加工工艺概述··········································································· 1

1.2机械加工工艺流程············································································ 1

1.3夹具概述························································································· 2

1.4机床夹具的功能··············································································· 3

1.5机床夹具的发展趋势········································································· 3

1.5.1机床夹具的现状·········································································· 3

1.5.2现代机床夹具的发展方向····························································· 4

第2章 加工工艺规程设计················································································ 5

2.1 零件的分析····················································································· 5

2.1.1 零件的作用··············································································· 5

2.1.2 零件的工艺分析········································································· 5

2.2 手柄座加工的主要问题和工艺过程设计所应采取的相应措施·················· 6

2.2.1 孔和平面的加工顺序··································································· 6

2.2.2加工方案选择············································································· 7

2.3 手柄座加工定位基准的选择······························································· 7

2.3.1 粗基准的选择············································································ 7

2.3.2 精基准的选择············································································ 7

2.4 手柄座加工主要工序安排·································································· 8

2.5 机械加工余量、工序尺寸及毛坯尺寸的确定······································· 10

2.6确定切削用量及基本工时(机动时间)·············································· 11

2.7 时间定额计算及生产安排································································ 19

第3章 铣14槽夹具设计················································································ 21

3.1设计要求······················································································· 21

3.2夹具设计······················································································· 21

3.2.1 定位基准的选择······································································ 21

3.2.2 切削力及夹紧力的计算···························································· 21

3.3定位误差的分析·············································································· 23

3.4 确定夹具体结构和总体结构····························································· 24

3.5夹具设计及操作的简要说明······························································ 25

第4章 钻¢14孔夹具设计············································································ 27

4.1设计要求······················································································· 27

4.2夹具设计······················································································· 30

4.2.1 定位基准的选择······································································ 30

4.2.2 切削力及夹紧力的计算···························································· 30

4.3定位误差的分析·············································································· 34

4.4 钻套、衬套、钻模板设计与选用······················································· 34

4.5 确定夹具体结构和总体结构····························································· 36

4.6夹具设计及操作的简要说明······························································ 37

总 结········································································································ 38

致 谢········································································································ 39

参 考 文 献································································································· 41