设计简介

摘 要

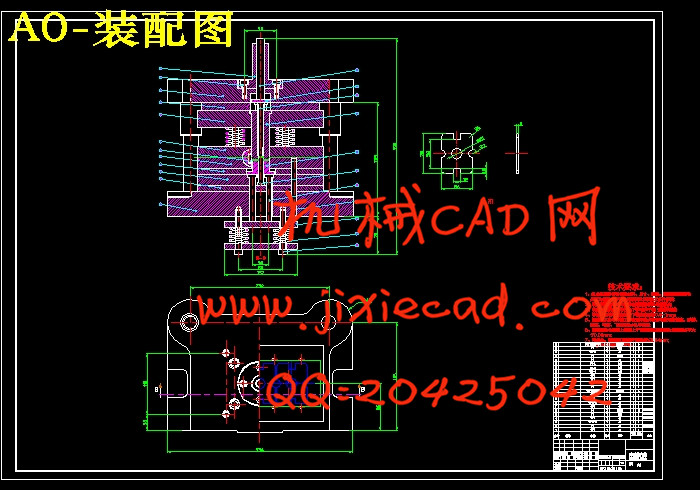

模具是现代工业的重要工艺设备,随着科学技术的不断进步,它在国民经济中占有越来越重要的地位,发展前景十分广阔。装备制造业在2007年的迅速发展,尤其是汽车和电子电器产品的高速增异形,为模具工业的发展营造了良好的市场环境。本次综合实训设计垫片的复合冲压模具,从零件的工艺性分析到模具结构的设计再到工艺计算,一直到最后的模具装配图。同时,模具也是机械制造业中技术先进、影响深远的重要工艺装备,具有生产效率高、材料利用率高、制件质量优良、工艺适应性好等特点,被广泛应用于汽车、机械、航天、航空、轻工、电子、电器、仪表等行业。随着我国汽车工业的迅猛发展,汽车性能不断提高,汽车零部件中对高精度、形状复杂锻件的需求量越来越大,锻造新工艺、省材、节能工艺等技术的开发对于新型汽车零件的生产尤为重要。我国冲压模具无论在数量上,还是在质量、技术和能力等方面都已有了很大发展,但与国民经济需求和世界先进水平相比,差距仍很大,一些大型、精密、复杂、异形寿命的高档模具每年仍大量 进口,特别是中高档轿车的覆盖件模具,目前仍主要依靠进口。

本文主要是以异形垫片为例,设计和制定异形垫片的工艺设计和工艺设备的选择以及冲压模具设计。

关键词:异形垫片;工艺设计;冲压模具;模具设计

ABSTRACT

Mold is mechanical manufacturing technology advanced, profoundly important technical equipment,High production efficiency, material with high efficiency and good quality, technology parts good adaptability etc. Characteristics. Widely used in motor vehicles, machinery, aerospace, aviation, light industry, electronics, electric appliances, instruments and other industries. With the rapid development of China's automobile industry, The car's performance to improve, Auto parts of high precision, complicated shape of forging an increasing demand for, Forging new craft, material, energy saving technology province technology development for new type of car parts production is especially important. Our country stamping die in the number no matter, or in quality, technology and ability are already has great development, But with the national economy needs and the advanced world level, compared to a gap still, Some large, sophisticated, complex, the long life of high-grade die every year in the importation of large still, Especially in high-grade car covering mould, at present still mainly rely on imports.

The paper is an inert round of forging production, Processing techniques, Design and manufacturing, some mould, including, fall round of forgings upsetting, eventually forging, and trimming punching production processing mould.Introduced again, trimming punching the design of the composite film.

Key words: Mould ;Finally bore;Flash tank;Clamp mouth

目 录

第一章 绪轮........................................1模具是现代工业的重要工艺设备,随着科学技术的不断进步,它在国民经济中占有越来越重要的地位,发展前景十分广阔。装备制造业在2007年的迅速发展,尤其是汽车和电子电器产品的高速增异形,为模具工业的发展营造了良好的市场环境。本次综合实训设计垫片的复合冲压模具,从零件的工艺性分析到模具结构的设计再到工艺计算,一直到最后的模具装配图。同时,模具也是机械制造业中技术先进、影响深远的重要工艺装备,具有生产效率高、材料利用率高、制件质量优良、工艺适应性好等特点,被广泛应用于汽车、机械、航天、航空、轻工、电子、电器、仪表等行业。随着我国汽车工业的迅猛发展,汽车性能不断提高,汽车零部件中对高精度、形状复杂锻件的需求量越来越大,锻造新工艺、省材、节能工艺等技术的开发对于新型汽车零件的生产尤为重要。我国冲压模具无论在数量上,还是在质量、技术和能力等方面都已有了很大发展,但与国民经济需求和世界先进水平相比,差距仍很大,一些大型、精密、复杂、异形寿命的高档模具每年仍大量 进口,特别是中高档轿车的覆盖件模具,目前仍主要依靠进口。

本文主要是以异形垫片为例,设计和制定异形垫片的工艺设计和工艺设备的选择以及冲压模具设计。

关键词:异形垫片;工艺设计;冲压模具;模具设计

ABSTRACT

Mold is mechanical manufacturing technology advanced, profoundly important technical equipment,High production efficiency, material with high efficiency and good quality, technology parts good adaptability etc. Characteristics. Widely used in motor vehicles, machinery, aerospace, aviation, light industry, electronics, electric appliances, instruments and other industries. With the rapid development of China's automobile industry, The car's performance to improve, Auto parts of high precision, complicated shape of forging an increasing demand for, Forging new craft, material, energy saving technology province technology development for new type of car parts production is especially important. Our country stamping die in the number no matter, or in quality, technology and ability are already has great development, But with the national economy needs and the advanced world level, compared to a gap still, Some large, sophisticated, complex, the long life of high-grade die every year in the importation of large still, Especially in high-grade car covering mould, at present still mainly rely on imports.

The paper is an inert round of forging production, Processing techniques, Design and manufacturing, some mould, including, fall round of forgings upsetting, eventually forging, and trimming punching production processing mould.Introduced again, trimming punching the design of the composite film.

Key words: Mould ;Finally bore;Flash tank;Clamp mouth

目 录

1.1 模具工业简介.................................1

1.2 模具分类.....................................3

1.3 冲压模具简介..................................3

1.4 我国冲压模具发展现状和趋.......................5

第二章 零件的工艺分析拟定..........................7

2.1冲裁件的工艺性分析.............................8

2.2确定冲压工艺方................................10

2.3选择模具结构形式..............................15

2.3.1 模具的形式.................................16

2.3.2 定位装置...................................16

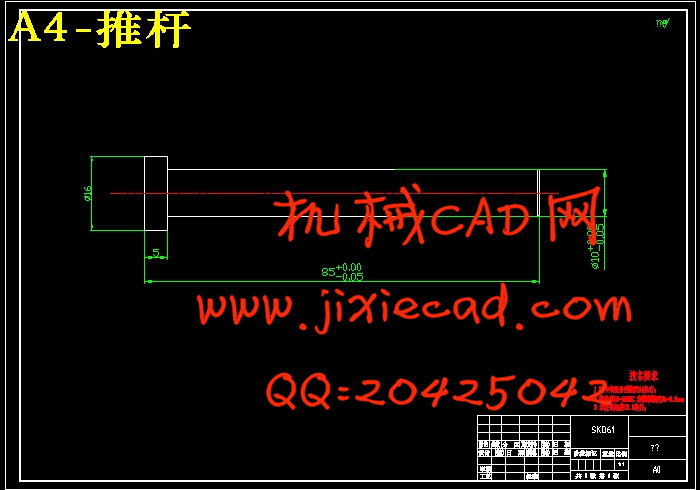

2.3.3 卸料装置...................................17

2.3.4 导向零件...................................18

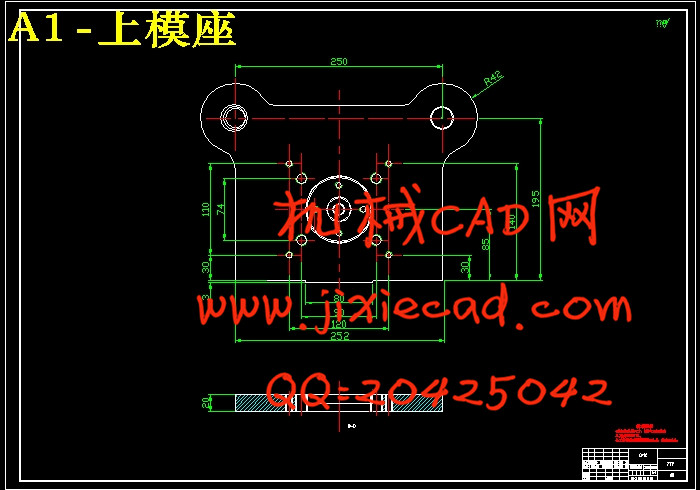

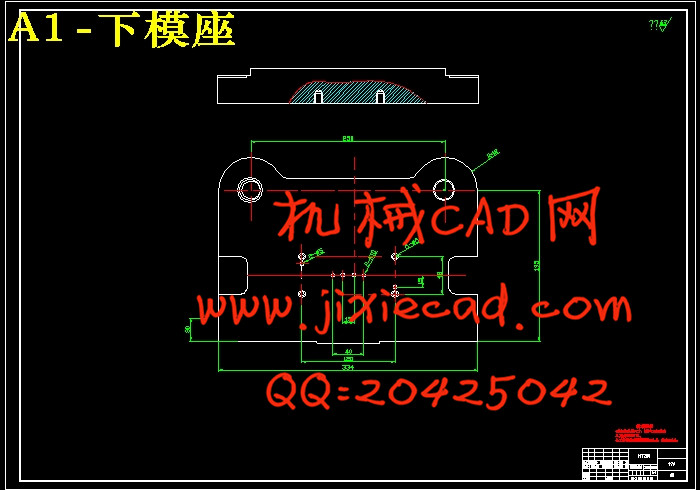

2.3.5 模架......................................19

第三章 必要的工艺计算..............................19

3.1排样设计与计算................................19

3.2计算冲压力....................................20

3.3计算模具压力中心..............................24

3.4计算模具刃口尺寸..............................22

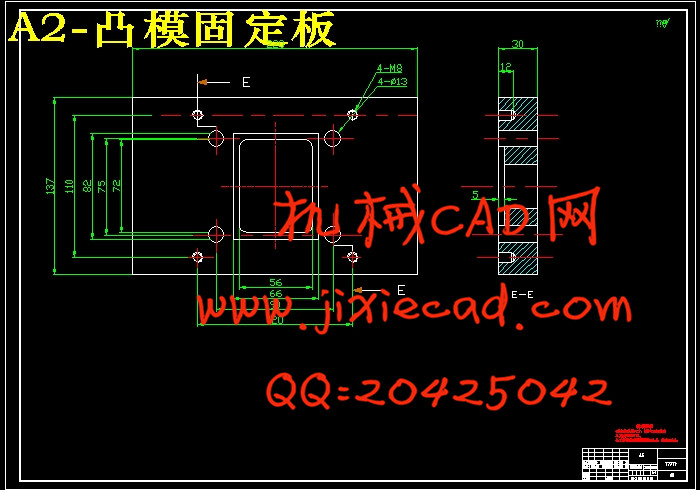

第四章 垫片复合模主要零件的设计计算...............22

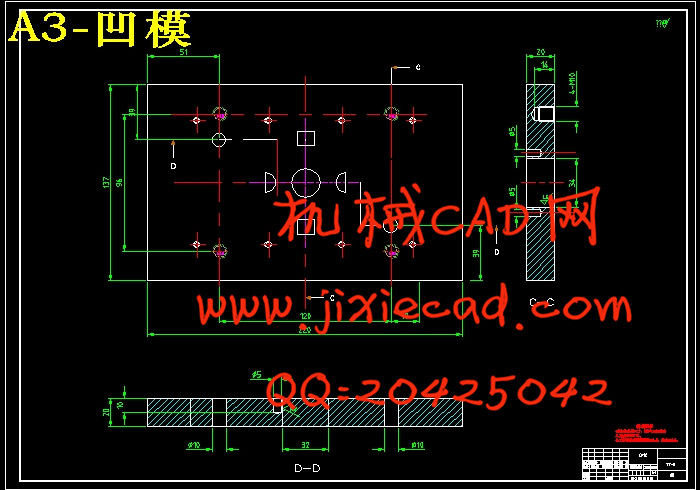

4.1落料凹模......................................23

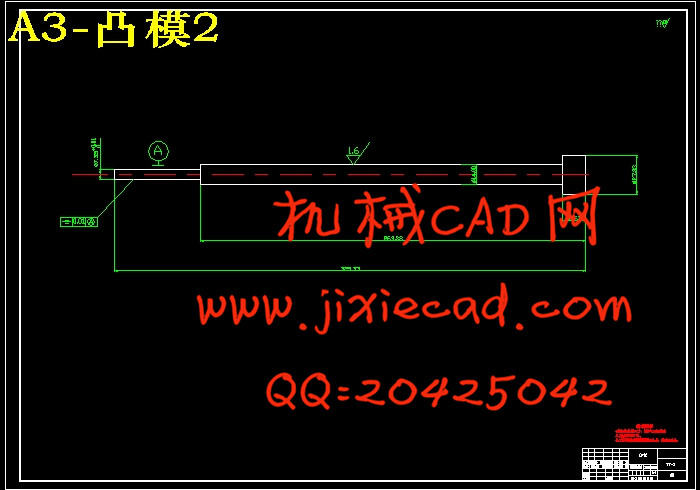

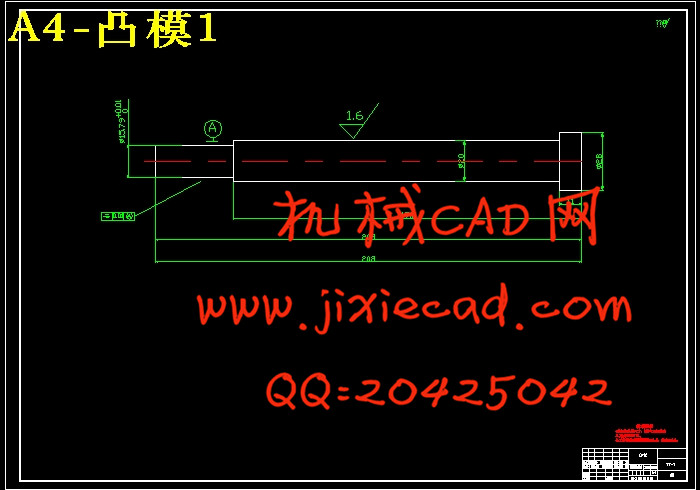

4.2冲孔凸模异形度及强度校核.......................23

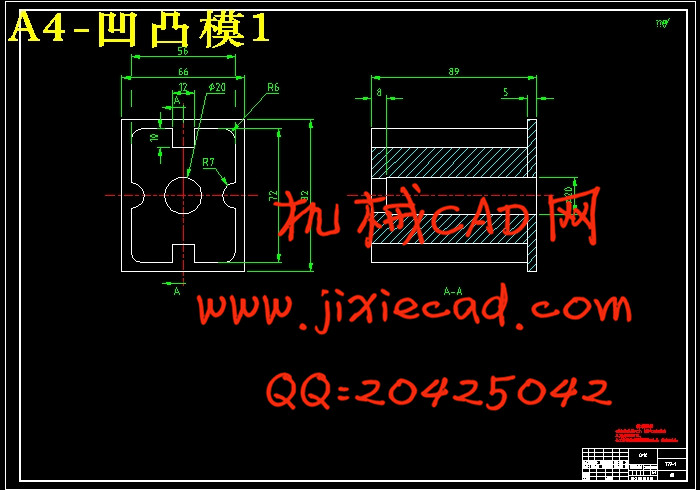

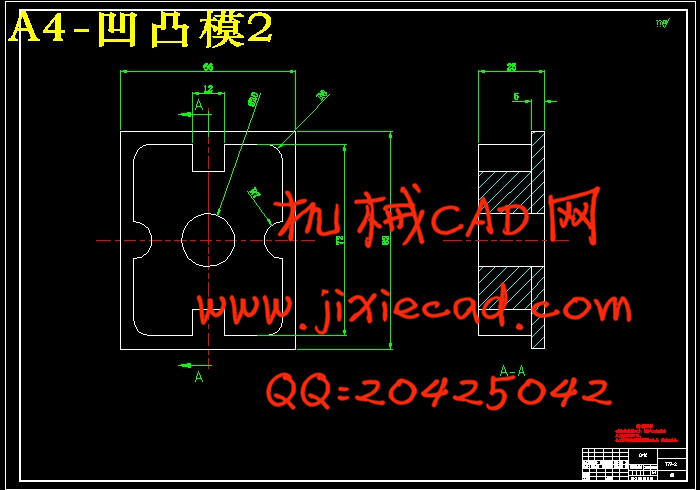

4.3凸凹模异形度确定及壁厚校核.....................24

4.4凸凹模固定板尺寸..............................24

4.5垫板结构与设计................................25

4.6卸料板的设计..................................26

第六章 压力机校核.................................26

5.1模柄孔的校核..............................27

5.2模具闭合高度的校核........................28

5.3压力机工作台尺寸的校核....................29

5.4冲裁力校核...............................29

注释...........................................26

参考文献.......................................27

附录...........................................28