设计简介

保持架冲压模具设计

摘要:本设计题目为保持架前半部分设计,落料拉深冲孔复合模设计,体现了拉深件冲压零件的设计要求、内容及方向,有一定的设计意义。通过对该零件的模具设计,进一步加强了我的冲压模具设计的基础知识,为设计更复杂的冲压件做好了铺垫和吸取了更深刻的经验

本设计运用冲压成型工艺及模具设计的基础知识,首先分析了该零件的材料和各方面的要求和拉深原理分析、拉深工艺方案的选择、冲孔和落料工艺方案的选择、模具结构设计计算为冲压工艺做好了准备;查资料材料的各力学性能,便于选取压力机,计算了各主要工作零件的尺寸,查资料选取的各零件的选用和安装方法。

本制件与其他拉深件不同,工序复杂,在这我做的是落料、拉深、冲预孔工序。冲压该零件时,普遍采用落料、拉深、冲孔、三道工序,生产效率低,成本也高。为此设计了该零件的落料、拉深、冲孔复合模具,是原三道工序合为一,大大提高了生产效率。

关键词:模具 拉深 冲孔

Stamping dies design

Abstract: This design topic is frame before half part design, design of compound die of blanking drawing piercing, reflects the design of deep drawing stamping parts requirements, content and direction, the design of a certain significance. Through the die design of the parts, to further strengthen the basic knowledge of stamping die design I, paving the way and draw a more profound experience of stamping design more complex parts.

This design using the basic knowledge of stamping forming process and die design, analyses, the parts of the materials and the requirements and the drawing principle drawing scheme selection, punching and blanking process scheme selection, die structure design calculation ready for stamping process; the mechanical properties to check information materials, to select the press, the main working parts size calculation, selection of various parts of the check data selection and installation method.

This product is different, and other drawing of complex processes, blanking, drawing, punching hole process in this I do is. The parts stamping, blanking, drawing, punching, three processes widely used, the production efficiency is low, the cost is high. For the design of the blanking, drawing, punching compound die of the part, is the original three processes are combined into one, greatly improving the efficiency of production.

Keywords:Punching die drawing

目录

1 绪论……………………………………………………………………1

1.1冲压模具的分类…………………………………………………………………1

1.2冲压模具零件的分类……………………………………………………………2

1.3本课题主要研究的内容及意义………………………………………………3

1.4保持架模具设计的设计思路…………………………………………………4

2 保持架冲压工艺分析…………………………………5

2.1 保持架的工艺性分析……………………………………………………………5

2.2 拉深工艺计算和工艺方案………………………………………………………6

2.2.1保持架工艺方案的确定……………………………………………………………7

2.2.2计算毛坯尺寸……………………………………………………………………………7

2.2.3冲预孔尺寸计算…………………………………………………………………………9

2.2.4排样…………………………………………………………………………………………10

2.2.5工序压力计算……………………………………………………………………………10

2.2.6落料韧口尺寸计算……………………………………………………………………12

2.2.7韧口尺寸计算……………………………………………………………………………13

3 复合模具主要零件…………………………………… 14

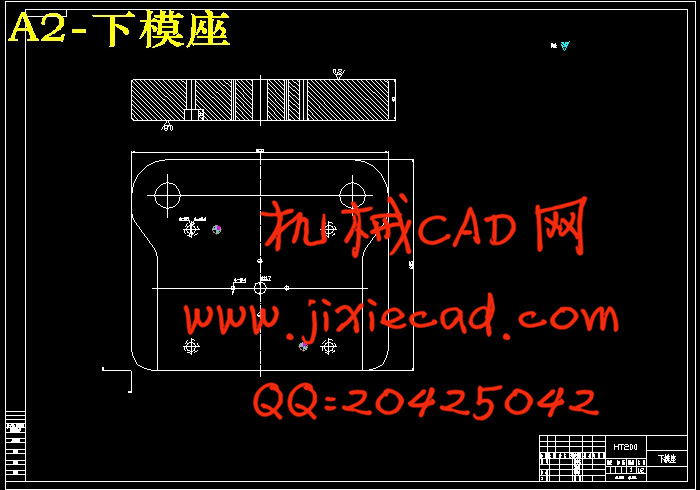

3.1复合模具主要零件设计…………………………………………………………14

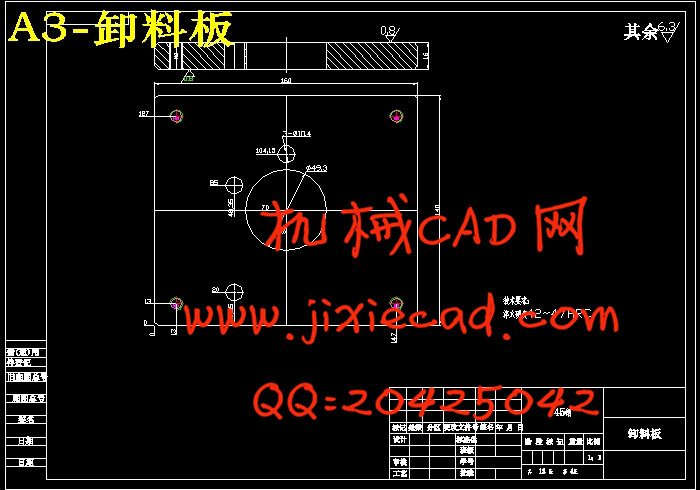

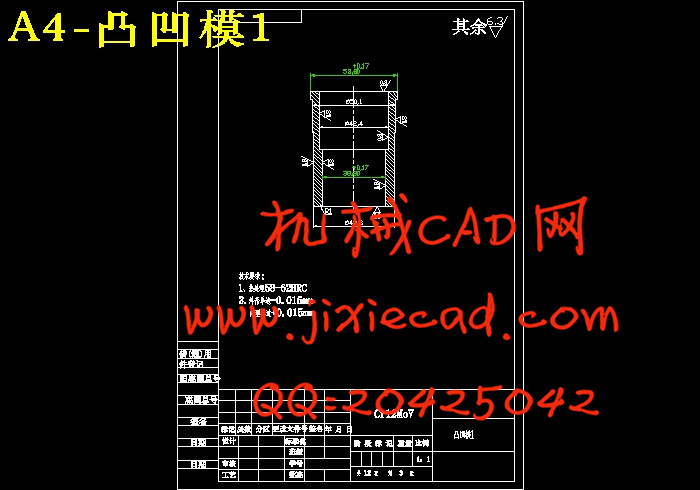

3.1.1凹凸模设计………………………………………………………………………………14

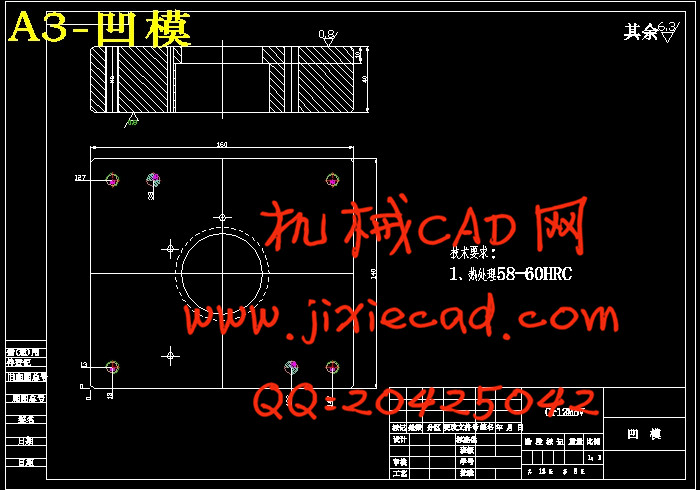

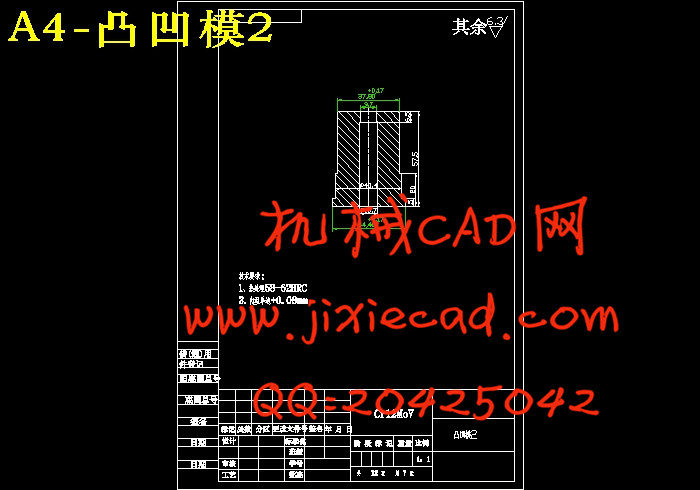

3.1.2凸凹模设计………………………………………………………………………………14

3.1.3落料凹模设计……………………………………………………………………………15

3.1.4模柄的选用………………………………………………………………………………15

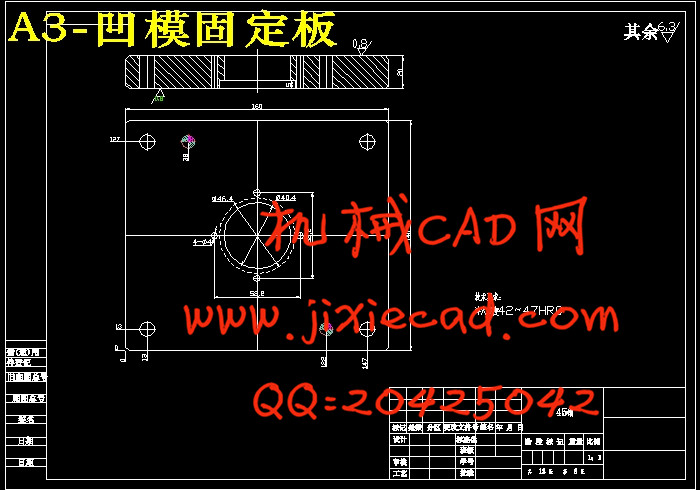

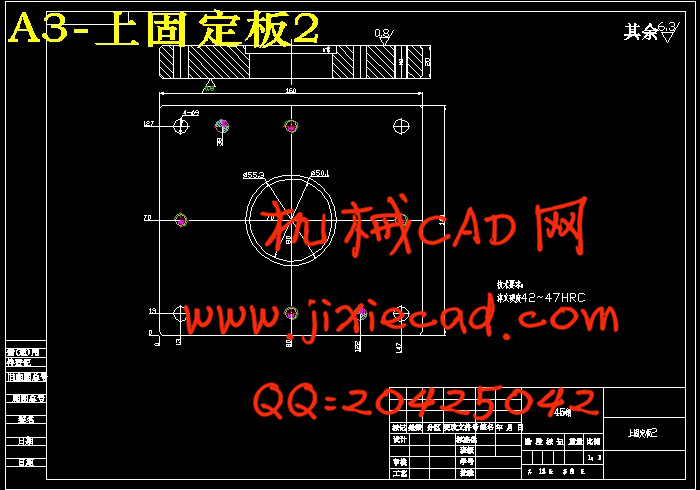

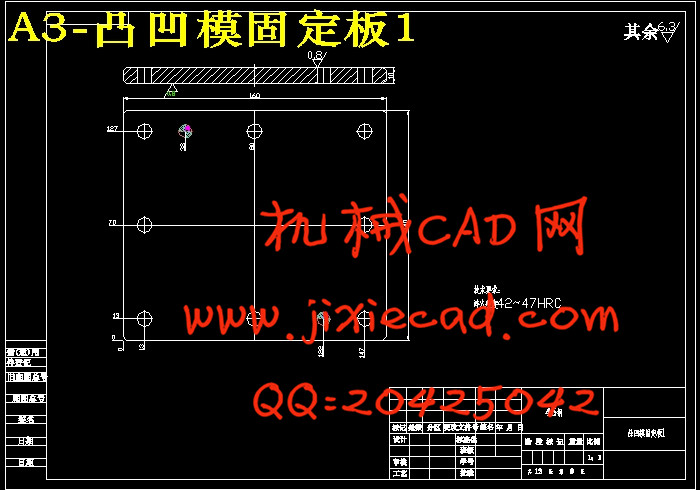

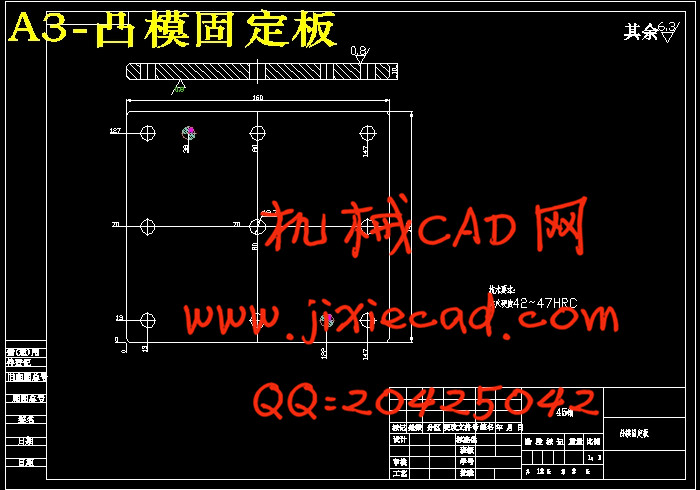

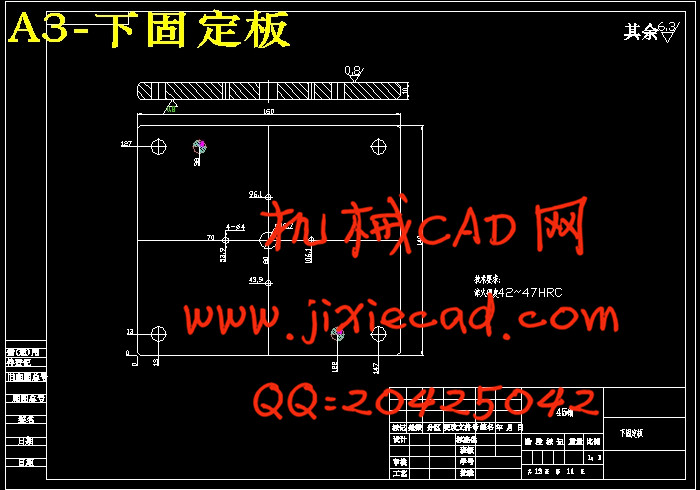

3.1.5固定板的设计……………………………………………………………………………15

3.2压力中心计算及压力机的选用………………………………………………17

4 模具装配和具体要求……………………………… 19

4.1模具装配…………………………………………………………………………19

4.2冲压模具具体要求………………………………………………………………19

4.3落料拉深复合模具装配特点…………………………………………………20

4.4复合模具零部件尺寸……………………………………………………………20

4.5复合模具总装配…………………………………………………………………21

4.6模具运动过程……………………………………………………………………21

4.7模具的调试要点…………………………………………………………………22

4.8调整方法…………………………………………………………………………23

5 结束语…………………………………………………………… 25

致谢 …………………………………………………………………… 26

参考文献…………………………………………………………… 27

摘要:本设计题目为保持架前半部分设计,落料拉深冲孔复合模设计,体现了拉深件冲压零件的设计要求、内容及方向,有一定的设计意义。通过对该零件的模具设计,进一步加强了我的冲压模具设计的基础知识,为设计更复杂的冲压件做好了铺垫和吸取了更深刻的经验

本设计运用冲压成型工艺及模具设计的基础知识,首先分析了该零件的材料和各方面的要求和拉深原理分析、拉深工艺方案的选择、冲孔和落料工艺方案的选择、模具结构设计计算为冲压工艺做好了准备;查资料材料的各力学性能,便于选取压力机,计算了各主要工作零件的尺寸,查资料选取的各零件的选用和安装方法。

本制件与其他拉深件不同,工序复杂,在这我做的是落料、拉深、冲预孔工序。冲压该零件时,普遍采用落料、拉深、冲孔、三道工序,生产效率低,成本也高。为此设计了该零件的落料、拉深、冲孔复合模具,是原三道工序合为一,大大提高了生产效率。

关键词:模具 拉深 冲孔

Stamping dies design

Abstract: This design topic is frame before half part design, design of compound die of blanking drawing piercing, reflects the design of deep drawing stamping parts requirements, content and direction, the design of a certain significance. Through the die design of the parts, to further strengthen the basic knowledge of stamping die design I, paving the way and draw a more profound experience of stamping design more complex parts.

This design using the basic knowledge of stamping forming process and die design, analyses, the parts of the materials and the requirements and the drawing principle drawing scheme selection, punching and blanking process scheme selection, die structure design calculation ready for stamping process; the mechanical properties to check information materials, to select the press, the main working parts size calculation, selection of various parts of the check data selection and installation method.

This product is different, and other drawing of complex processes, blanking, drawing, punching hole process in this I do is. The parts stamping, blanking, drawing, punching, three processes widely used, the production efficiency is low, the cost is high. For the design of the blanking, drawing, punching compound die of the part, is the original three processes are combined into one, greatly improving the efficiency of production.

Keywords:Punching die drawing

目录

1 绪论……………………………………………………………………1

1.1冲压模具的分类…………………………………………………………………1

1.2冲压模具零件的分类……………………………………………………………2

1.3本课题主要研究的内容及意义………………………………………………3

1.4保持架模具设计的设计思路…………………………………………………4

2 保持架冲压工艺分析…………………………………5

2.1 保持架的工艺性分析……………………………………………………………5

2.2 拉深工艺计算和工艺方案………………………………………………………6

2.2.1保持架工艺方案的确定……………………………………………………………7

2.2.2计算毛坯尺寸……………………………………………………………………………7

2.2.3冲预孔尺寸计算…………………………………………………………………………9

2.2.4排样…………………………………………………………………………………………10

2.2.5工序压力计算……………………………………………………………………………10

2.2.6落料韧口尺寸计算……………………………………………………………………12

2.2.7韧口尺寸计算……………………………………………………………………………13

3 复合模具主要零件…………………………………… 14

3.1复合模具主要零件设计…………………………………………………………14

3.1.1凹凸模设计………………………………………………………………………………14

3.1.2凸凹模设计………………………………………………………………………………14

3.1.3落料凹模设计……………………………………………………………………………15

3.1.4模柄的选用………………………………………………………………………………15

3.1.5固定板的设计……………………………………………………………………………15

3.2压力中心计算及压力机的选用………………………………………………17

4 模具装配和具体要求……………………………… 19

4.1模具装配…………………………………………………………………………19

4.2冲压模具具体要求………………………………………………………………19

4.3落料拉深复合模具装配特点…………………………………………………20

4.4复合模具零部件尺寸……………………………………………………………20

4.5复合模具总装配…………………………………………………………………21

4.6模具运动过程……………………………………………………………………21

4.7模具的调试要点…………………………………………………………………22

4.8调整方法…………………………………………………………………………23

5 结束语…………………………………………………………… 25

致谢 …………………………………………………………………… 26

参考文献…………………………………………………………… 27