设计简介

上端盖冲压模具设计与制造

摘 要

本设计题目为上端盖零件冲压成形工艺与模具设计,含有落料、弯曲、拉伸等工序,此设计体现了这类零件的设计要求、内容及方向,具有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者冲裁模设计的基础知识,为设计更复杂的冲裁模具做好了铺垫和吸取了更深刻的经验。

本设计运用冲压工艺及模具设计的基础知识,首先分析了工件的工艺要求,为选取排样的类型做好了准备;然后估算了板料的选取,便于导尺的宽度及确定排样的方法;最后分析了工件的特征,确定模具的设计参数、设计要点及卸料装置。

本工件为薄板的落料、拉深件,但是工件的毛坯直径较大,所以在选取压力机时应该注意,且钢材料的屈服强度也较大。

关键词:冲裁模具 ;模具设计;落料;拉深;屈服强度;压力机

上端盖冲压模具设计与制造

Abstract

This design of the maze is last hold cover parts stamping and die design process, containing Blanking, Bending, Drawing processes, This design reflects such parts design, content and direction, with a certain sense of design. Through parts mold design, further strengthening the designers Die basis for the design of knowledge, for the design of more complex stamping die has laid a good groundwork and learned a more profound experience.

This design and use of die stamping process designed on the basis of knowledge, the first analysis of the technological requirements of the workpiece, To select the type of layout well prepared; then estimate the sheet metal selection, facilitate I. foot width and determine the layout; Finally, the workpiece characteristics, and the mold design parameters, Design and unloading devices.

The workpiece for the blanking plate, drawing 'punch pieces, but the rough workpiece diameter larger, Therefore, in selecting press should pay attention to when and steel material yield strength is greater.

Key words : Blanking die ;mold designing ;Drawing; yield strength; Press machine

目 录

绪 论 1

1 国内模具的现状和发展趋势 1

2 国外模具的现状和发展趋势 3

3 落料、弯曲、拉伸模具设计与制造方面 4

1 零件冲压工艺分析 5

1.1制件图及要求 5

1.2 零件工艺分析 5

1.3 冲压工艺方案选择 5

1.4 排样工艺计算 5

2 工作零件刃口尺寸的计算 11

2.1落料加工工序 11

2.2 卸料橡皮的设计 12

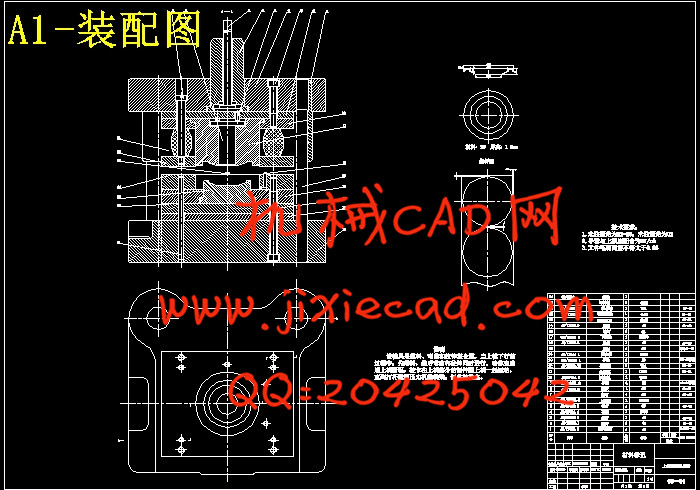

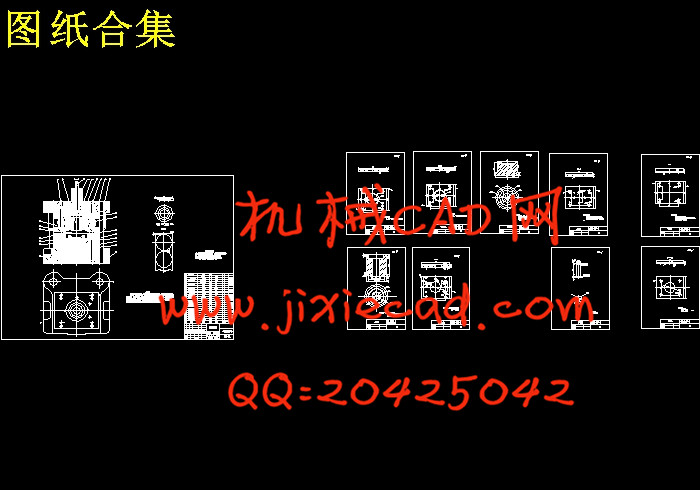

3 模具的总体设计 15

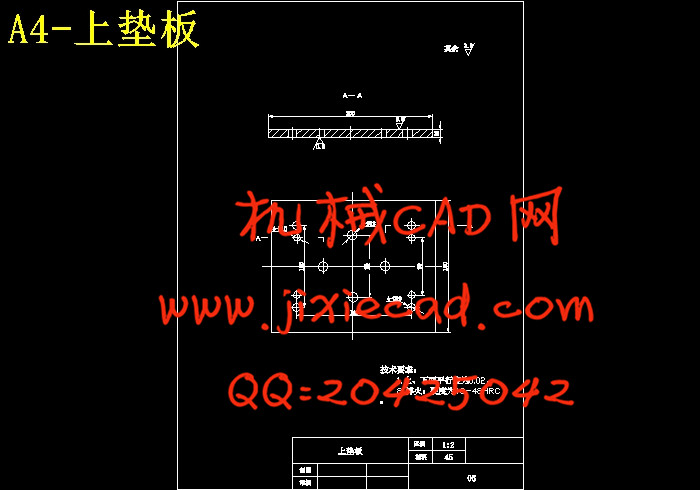

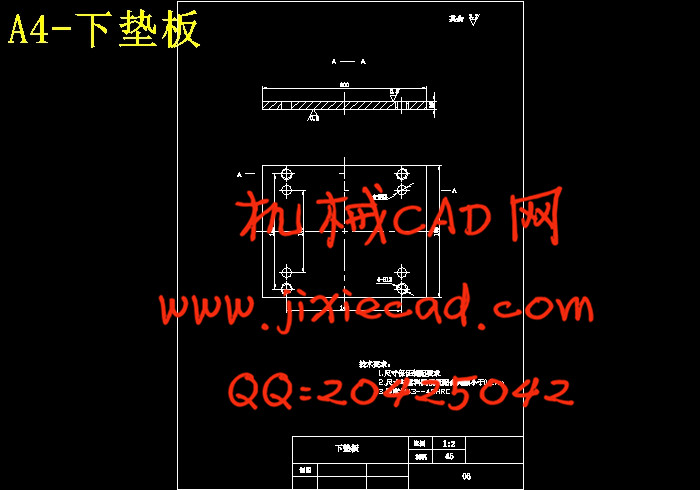

3.1主要零部件的设计 15

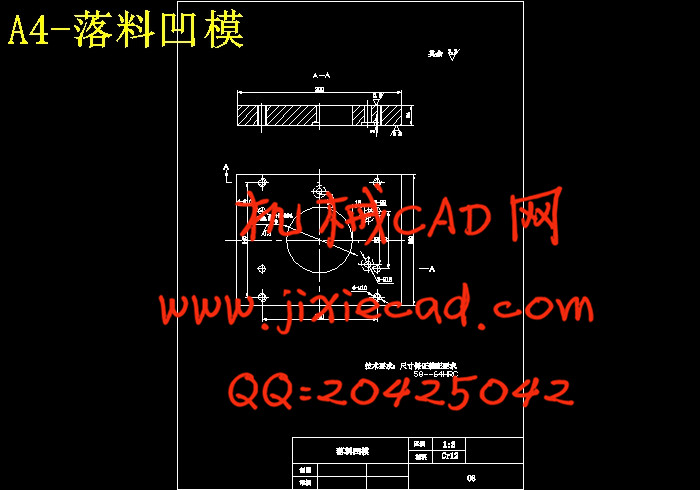

3.2 落料凹模的设计 16

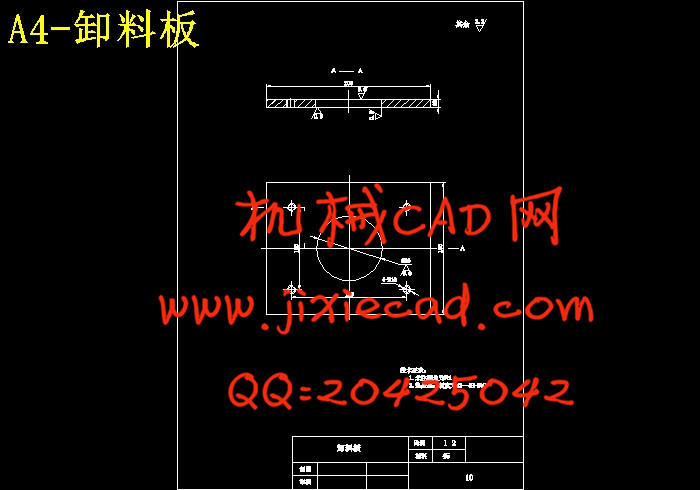

3.3卸料板的设计 17

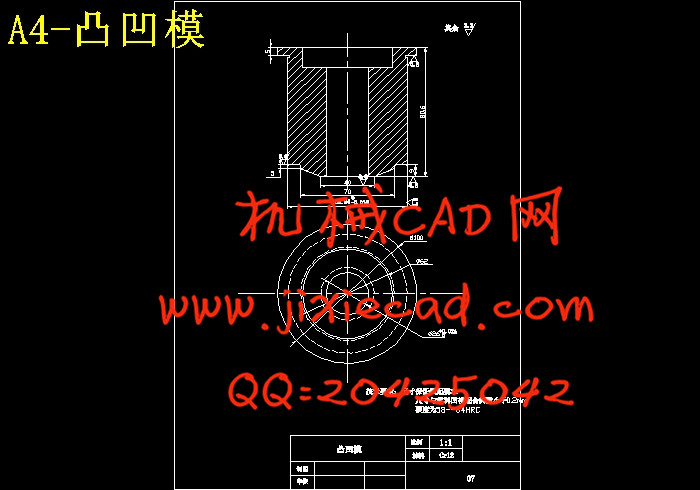

3.4凸凹模的设计 18

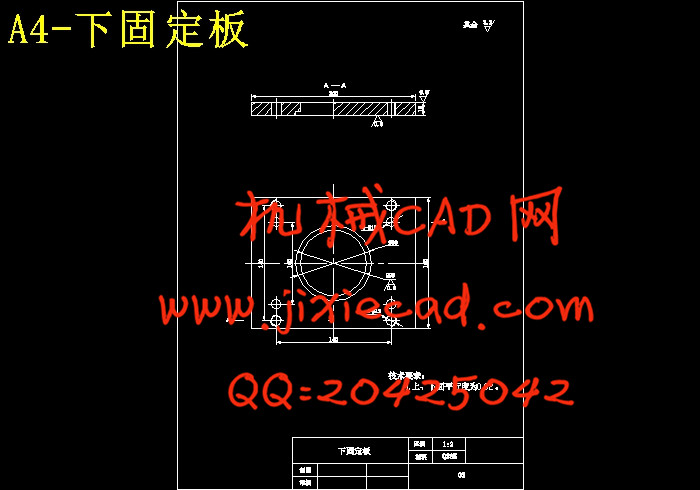

3.5定位零件的设计 20

3.6模架及其他零件设计 21

总结 23

结束语 24

致谢 25

参考文献 26

摘 要

本设计题目为上端盖零件冲压成形工艺与模具设计,含有落料、弯曲、拉伸等工序,此设计体现了这类零件的设计要求、内容及方向,具有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者冲裁模设计的基础知识,为设计更复杂的冲裁模具做好了铺垫和吸取了更深刻的经验。

本设计运用冲压工艺及模具设计的基础知识,首先分析了工件的工艺要求,为选取排样的类型做好了准备;然后估算了板料的选取,便于导尺的宽度及确定排样的方法;最后分析了工件的特征,确定模具的设计参数、设计要点及卸料装置。

本工件为薄板的落料、拉深件,但是工件的毛坯直径较大,所以在选取压力机时应该注意,且钢材料的屈服强度也较大。

关键词:冲裁模具 ;模具设计;落料;拉深;屈服强度;压力机

上端盖冲压模具设计与制造

Abstract

This design of the maze is last hold cover parts stamping and die design process, containing Blanking, Bending, Drawing processes, This design reflects such parts design, content and direction, with a certain sense of design. Through parts mold design, further strengthening the designers Die basis for the design of knowledge, for the design of more complex stamping die has laid a good groundwork and learned a more profound experience.

This design and use of die stamping process designed on the basis of knowledge, the first analysis of the technological requirements of the workpiece, To select the type of layout well prepared; then estimate the sheet metal selection, facilitate I. foot width and determine the layout; Finally, the workpiece characteristics, and the mold design parameters, Design and unloading devices.

The workpiece for the blanking plate, drawing 'punch pieces, but the rough workpiece diameter larger, Therefore, in selecting press should pay attention to when and steel material yield strength is greater.

Key words : Blanking die ;mold designing ;Drawing; yield strength; Press machine

目 录

绪 论 1

1 国内模具的现状和发展趋势 1

2 国外模具的现状和发展趋势 3

3 落料、弯曲、拉伸模具设计与制造方面 4

1 零件冲压工艺分析 5

1.1制件图及要求 5

1.2 零件工艺分析 5

1.3 冲压工艺方案选择 5

1.4 排样工艺计算 5

2 工作零件刃口尺寸的计算 11

2.1落料加工工序 11

2.2 卸料橡皮的设计 12

3 模具的总体设计 15

3.1主要零部件的设计 15

3.2 落料凹模的设计 16

3.3卸料板的设计 17

3.4凸凹模的设计 18

3.5定位零件的设计 20

3.6模架及其他零件设计 21

总结 23

结束语 24

致谢 25

参考文献 26