设计简介

三四速轮锻模和切边冲孔复合模设计

摘要

在模锻设备上,利用高强度锻模,使金属坯料在模膛内受压产生塑性变形,而获得所需形状、尺寸以及内部质量锻件的加工方法称为模锻。模锻是金属材料加工方法之一,在现代制造业中占有重要的地位。在变形过程中由于模膛对金属坯料流动的限制,因而锻造终了时可获得与模膛形状相符的模锻件。根据锻造工艺的不同,热模锻可以分为单工序热模锻和多工位热模锻。单工序热模锻一般采用摩擦压力机、机械压力机、锤、油压机等压力加工设备进行锻造,以人工方式取放工件;多工位热模锻一般是采用热模锻压力机进行锻造,送料一般采用步进梁机械手以提高生产效率和送料精度。此外,根据有无飞边的不同,还可以分为闭式热模锻和开式热模锻

关键词:锻模;热锻锻;锻造工艺;锤压机。

Clapboard Flange Forging Die and Trimming Punching Compound Mould Design

Abstract

In die forging equipment, use high strength forging die, the metal blank mould in the chamber pressure produce plastic deformation, and have the shape, size and internal quality forgings processing method called die forging. Die forging is the metal material processing methods in one of the modern manufacturing occupies an important position. In the process of deformation due to die of metal flow bore blank restrictions, and at the end of the forging can obtain and mode shape of the chamber is forged pieces. According to the different forging process, hot die forging process can be divided into single hot die forging and progressive hot die forging. Single hot die forging process usually adopts the friction press, mechanical press, hammer, hydraulic press pressure on forging processing equipment, to artificially way take a problem; Progressive hot die forging is generally used for hot die-forging press forging, feed general use of the walking beam manipulator to increase production efficiency and precision feeding. In addition, according to the different without flash, can also be divided into closed hot die forging and open type hot die forging.

Key words: Forging die; Hot forging forging; Forging process; Hammer pressure machine.

目 录

1.绪论……………………………………………………………….............................1

1.1课题背景及目的…………………………………………………………………1

1.2国内外锻造模具的发展现状……………………………………………………1

1.3国内锻造模具的发展方向………………………………………………………3

2 课题分析拟定 4

2.1零件工艺性分析…………………………………………………………………4

2.2确定工艺方案……………………………………………………………………5

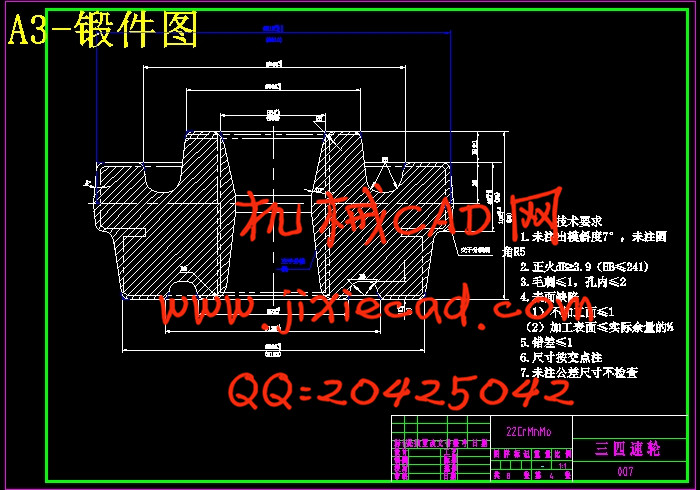

3 根据零件图制定锻件图 6

3.1 确定分型面…………………………………………………………………...6

3.2 加工余量及公差……………………………………………………………...6

3.3 技术条件……………………………………………………………………...8

3.4 模锻斜度……………………………………………………………………...8

3.2 圆角半径……………………………………………………………………...9

4冲孔连皮设计 10

5.设计终端模膛 11

5.1绘制齿轮热锻件图……………………………………………………………...11

5.2计算设计飞边槽的尺寸………………………………………………………. .11

5.3钳口的确定……………………………………………………………………..13

6.确定终锻模设备吨位 14

6.1 热模锻曲柄压力机的确定…………………………………………………….14

6.2 公称吨位的确定……………………………………………………………….14

6.3 压力吨位的计算……………………………………………………………….14

6.4 锻锤吨位的确定……………………………………………………………….15

7.设计制坯模锻 16

7.1拔长模膛………………………………………………………………………..16

7.2滚挤模膛………………………………………………………………………..16

7.3弯曲模膛………………………………………………………………………..16

7.4切断模膛………………………………………………………………………..17

7.5制坯工步的确定………………………………………………………………..17

8.确定坯料长度 18

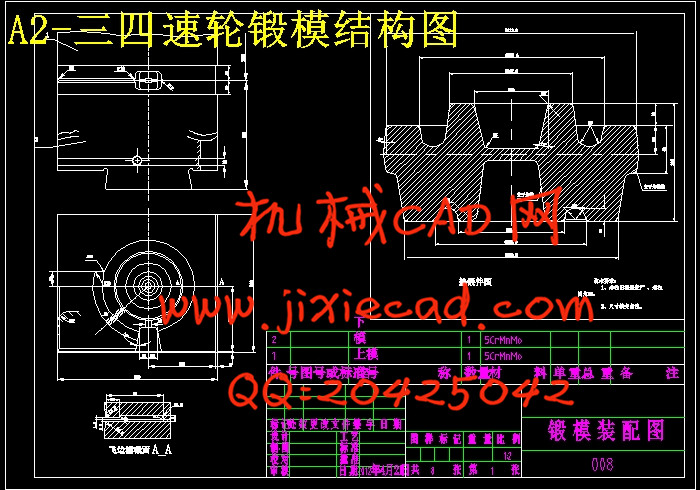

9.锻模结构设计 19

9.1模膛布置………………………………………………………………………..19

9.2镦粗台的设计…………………………………………………………………..19

9.3模块尺寸及要求………………………………………………………………..19

9.4模块材料………………………………………………………………………..20

9.5燕尾槽尺寸……………………………………………………………………..20

10.模锻工艺流程 21

11.模锻后续工序 22

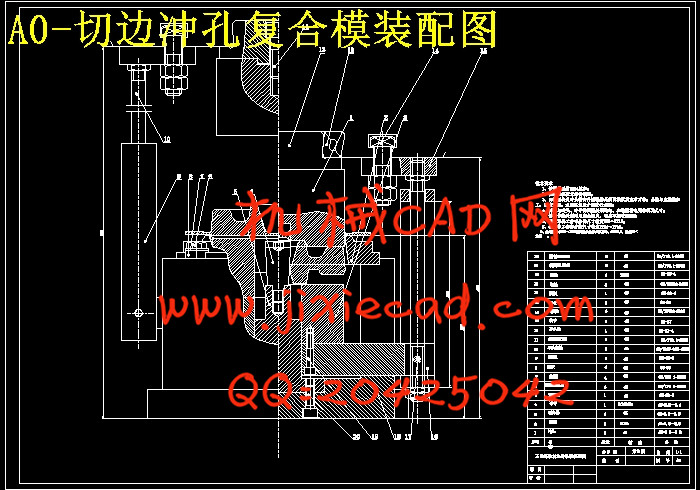

11.1切边与冲孔…………………………………………………………………….22

11.1.1切边和冲孔的方式及模具类型 22

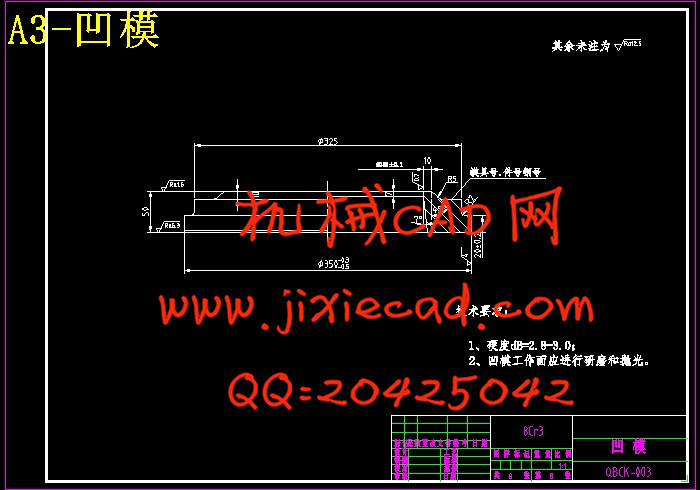

11.1.2切边模 23

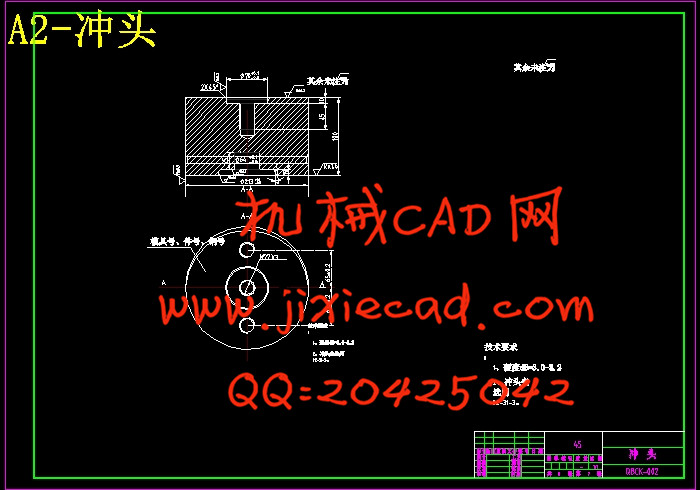

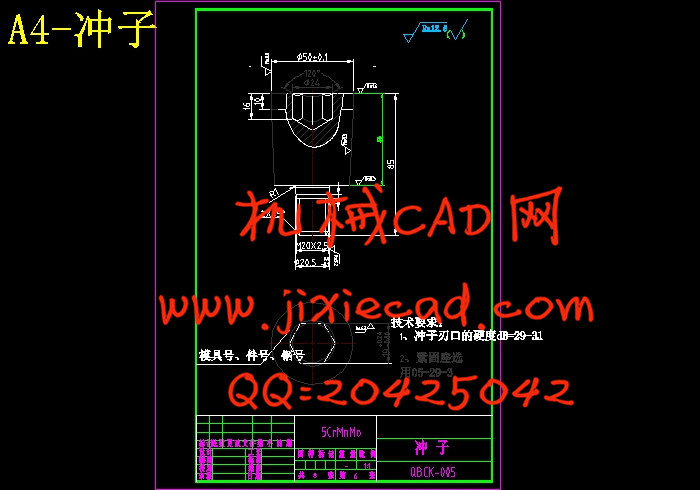

11.1.3切边冲头的设计和固定方法 25

11.2切边冲孔复合膜……………………………………………………………….26

12.锻模使用时必须注意的问题 28

结论 29

致谢 30

参考文献 31

摘要

在模锻设备上,利用高强度锻模,使金属坯料在模膛内受压产生塑性变形,而获得所需形状、尺寸以及内部质量锻件的加工方法称为模锻。模锻是金属材料加工方法之一,在现代制造业中占有重要的地位。在变形过程中由于模膛对金属坯料流动的限制,因而锻造终了时可获得与模膛形状相符的模锻件。根据锻造工艺的不同,热模锻可以分为单工序热模锻和多工位热模锻。单工序热模锻一般采用摩擦压力机、机械压力机、锤、油压机等压力加工设备进行锻造,以人工方式取放工件;多工位热模锻一般是采用热模锻压力机进行锻造,送料一般采用步进梁机械手以提高生产效率和送料精度。此外,根据有无飞边的不同,还可以分为闭式热模锻和开式热模锻

关键词:锻模;热锻锻;锻造工艺;锤压机。

Clapboard Flange Forging Die and Trimming Punching Compound Mould Design

Abstract

In die forging equipment, use high strength forging die, the metal blank mould in the chamber pressure produce plastic deformation, and have the shape, size and internal quality forgings processing method called die forging. Die forging is the metal material processing methods in one of the modern manufacturing occupies an important position. In the process of deformation due to die of metal flow bore blank restrictions, and at the end of the forging can obtain and mode shape of the chamber is forged pieces. According to the different forging process, hot die forging process can be divided into single hot die forging and progressive hot die forging. Single hot die forging process usually adopts the friction press, mechanical press, hammer, hydraulic press pressure on forging processing equipment, to artificially way take a problem; Progressive hot die forging is generally used for hot die-forging press forging, feed general use of the walking beam manipulator to increase production efficiency and precision feeding. In addition, according to the different without flash, can also be divided into closed hot die forging and open type hot die forging.

Key words: Forging die; Hot forging forging; Forging process; Hammer pressure machine.

目 录

1.绪论……………………………………………………………….............................1

1.1课题背景及目的…………………………………………………………………1

1.2国内外锻造模具的发展现状……………………………………………………1

1.3国内锻造模具的发展方向………………………………………………………3

2 课题分析拟定 4

2.1零件工艺性分析…………………………………………………………………4

2.2确定工艺方案……………………………………………………………………5

3 根据零件图制定锻件图 6

3.1 确定分型面…………………………………………………………………...6

3.2 加工余量及公差……………………………………………………………...6

3.3 技术条件……………………………………………………………………...8

3.4 模锻斜度……………………………………………………………………...8

3.2 圆角半径……………………………………………………………………...9

4冲孔连皮设计 10

5.设计终端模膛 11

5.1绘制齿轮热锻件图……………………………………………………………...11

5.2计算设计飞边槽的尺寸………………………………………………………. .11

5.3钳口的确定……………………………………………………………………..13

6.确定终锻模设备吨位 14

6.1 热模锻曲柄压力机的确定…………………………………………………….14

6.2 公称吨位的确定……………………………………………………………….14

6.3 压力吨位的计算……………………………………………………………….14

6.4 锻锤吨位的确定……………………………………………………………….15

7.设计制坯模锻 16

7.1拔长模膛………………………………………………………………………..16

7.2滚挤模膛………………………………………………………………………..16

7.3弯曲模膛………………………………………………………………………..16

7.4切断模膛………………………………………………………………………..17

7.5制坯工步的确定………………………………………………………………..17

8.确定坯料长度 18

9.锻模结构设计 19

9.1模膛布置………………………………………………………………………..19

9.2镦粗台的设计…………………………………………………………………..19

9.3模块尺寸及要求………………………………………………………………..19

9.4模块材料………………………………………………………………………..20

9.5燕尾槽尺寸……………………………………………………………………..20

10.模锻工艺流程 21

11.模锻后续工序 22

11.1切边与冲孔…………………………………………………………………….22

11.1.1切边和冲孔的方式及模具类型 22

11.1.2切边模 23

11.1.3切边冲头的设计和固定方法 25

11.2切边冲孔复合膜……………………………………………………………….26

12.锻模使用时必须注意的问题 28

结论 29

致谢 30

参考文献 31