设计简介

摘要:冲压模具是模具工业的重要组成部分,它是工业生产中的重要工艺装备。冲压模具主要包括冲裁模具、弯曲模具、拉深模具、多工位级进模、简单模具等等。

随着模具工业的发展,冲压技术在机械、航空、汽车、摩托车等行业中应用十分广泛,是现代工业生产的重要手段和发展方向。冲压工艺具有生产率高、生产成本低、材料利用率高、能成形复杂零件、适合大批量生产等优点,在某些领域已取代机械加工,并正逐步扩大其工艺范围。因此,冲压技术对发展生产、增强效益、更新产品等方面具有重要作用。

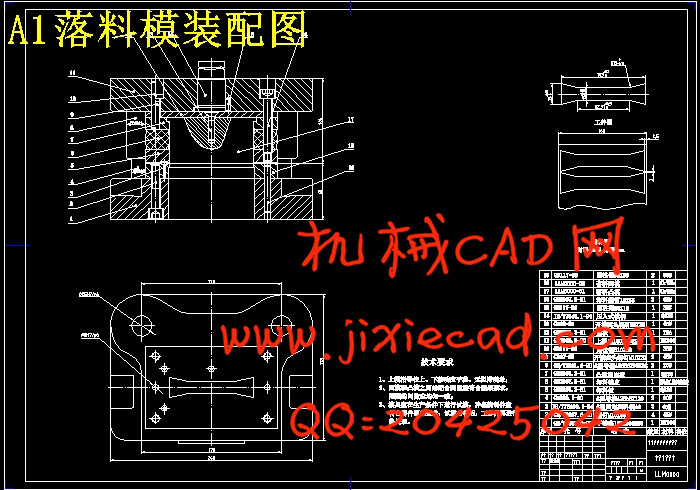

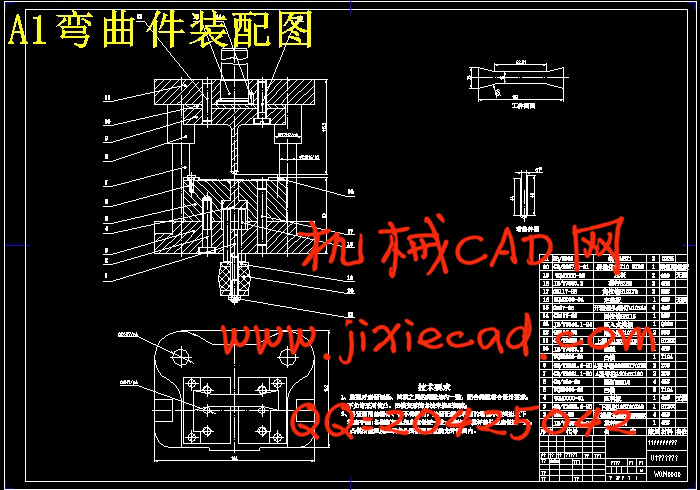

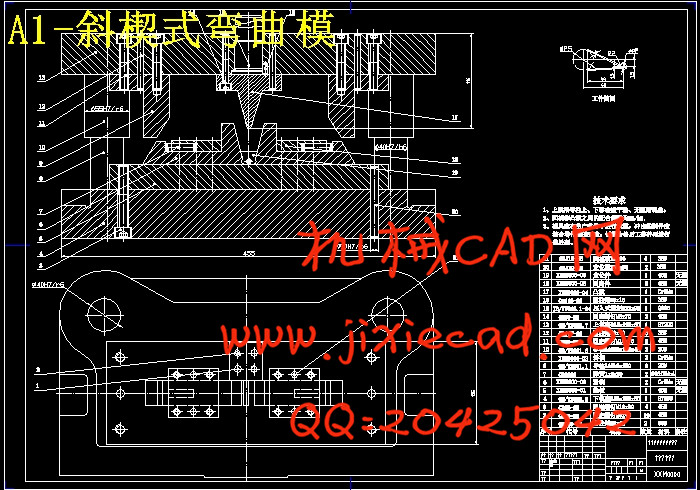

本课题的生产实践性非常强,所以在设计时要考虑实际生产条件。此论文的主要特点是通过设计一套模具使其同时满足两个零件的加工。首先对零件进行冲裁和弯曲工艺分析,由于零件结构简单、工艺性较好,所以属于中批量的生产采用单工序模比较好。然后确定工艺方案为落料、弯曲、最后成形,计算冲压力确定模具工作部分尺寸及公差来选取模具的结构。最后绘制落料模和弯曲模的装配图,并且拆绘一些主要零件图。本课题的关键是合理选择模具间隙和在弯曲时考虑弯曲件的回弹,这些因素对零件的质量有重要影响。

关键词:冲压模 弯曲模 冲压模具标准件 工艺分析 冲压模间隙

Abstract: Stamping die plays a very important part in die industry, it is one of the significant process equipment industry process. The principal stamping dies are blanking die, bending die, multiple station progressive die, simple die and other die, etc.

With the development of mould industry, stamping technology is very applied extensively in the professions, such as machinery, aviation, automobile and motorcycle. It is the important means of modem industrial production and develops direction. The advantages of stamping technology such as productivity high, cost lowly, utilization high, become complex element and suit a large quantity of productive. In some fields, it has replaced machining, the technology scope is enlarging step by step. Therefore stamping technology has important role for developing production, strengthening benefit and update the product, etc.

The production practicality of this program is very strong, so you should consider actual production condition when designing. The major characteristic of this paper is to make it at the same time satisfy the processing of two elements through designing a set of mould. First you should rush to cut and bend technology analysis for the element. Since the element structure is simple and technology better, so belong to only process mould in the production of batch. Then, the technology scheme is falling to expect, bending and becoming shape finally, and calculate the stamping force structure that determines mould working partial size and tolerance to select mould. finally the assembly drawing of stamping die and bending die, and takes apart to paint some major part drawings. The key of this program selects reasonably mould gap, and when bending, consider the spring back of curved, these factors have influence for the quality of element.

Keywords: stamping die bending die standard units of stamping die technical analysis clearance of punching mould

目 录

1 绪论

1.1课题背景与研究意义……………………………………………………………… 1

1.2模具行业现状与发展趋势………………………………………………………… 1

1.3课题研究的主要内容和目标……………………………………………………… 2

1.3.1课题研究的主要内容…………………………………………………………… 2

1.3.2课题研究的主要目标…………………………………………………………… 2

2 工艺方案设计

2.1零件的工艺性分析………………………………………………………………… 3

2.2加工工艺方案的确定……………………………………………………………… 4

3 冲裁模设计

3.1毛坯尺寸计算与冲裁工艺分析…………………………………………………… 5

3.1.1毛坯尺寸计算…………………………………………………………………… 5

3.1.2冲裁工艺分析…………………………………………………………………… 6

3.2工件排样与搭边…………………………………………………………………… 6

3.2.1排样……………………………………………………………………………… 6

3.2.2搭边……………………………………………………………………………… 7

3.3冲裁间隙…………………………………………………………………………… 8

3.4冲裁力计算………………………………………………………………………… 9

3.5模具压力中心计算………………………………………………………………… 11

3.6凸、凹模刃口尺寸计算…………………………………………………………… 12

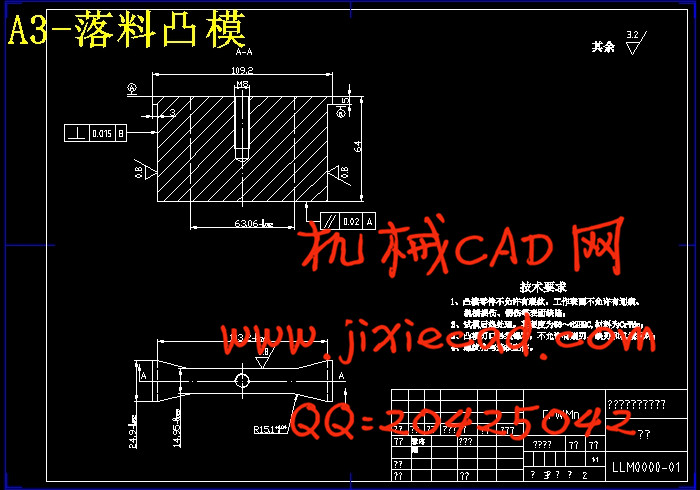

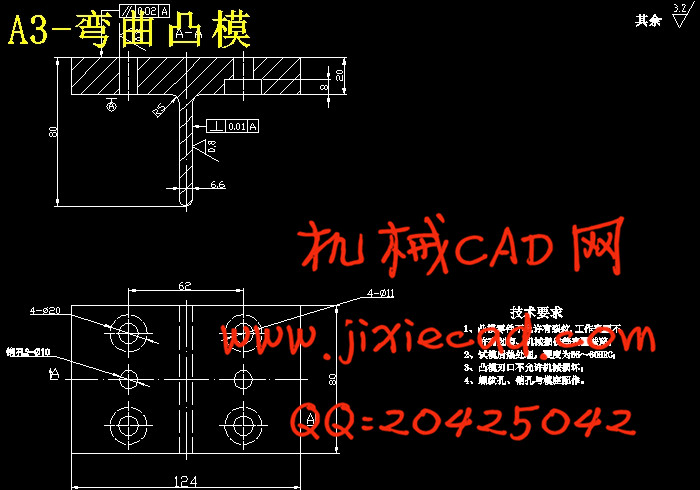

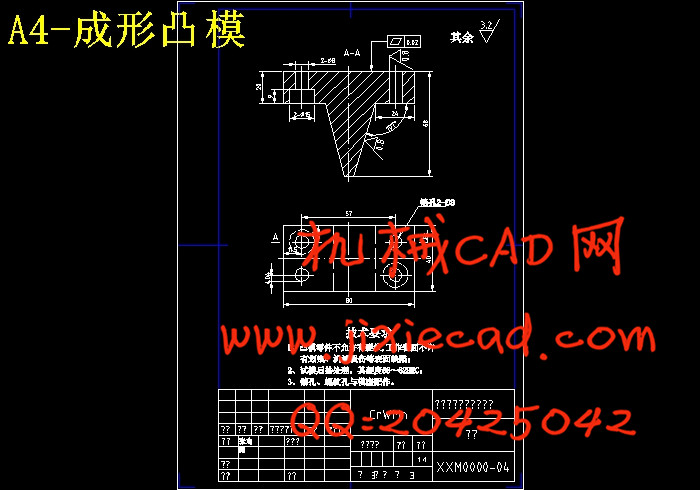

3.7凸、凹模结构设计………………………………………………………………… 15

3.7.1凸模结构设计…………………………………………………………………… 15

3.7.2凹模结构设计…………………………………………………………………… 17

3.8冲模的闭合高度…………………………………………………………………… 18

3.9结构件与标准件选用……………………………………………………………… 19

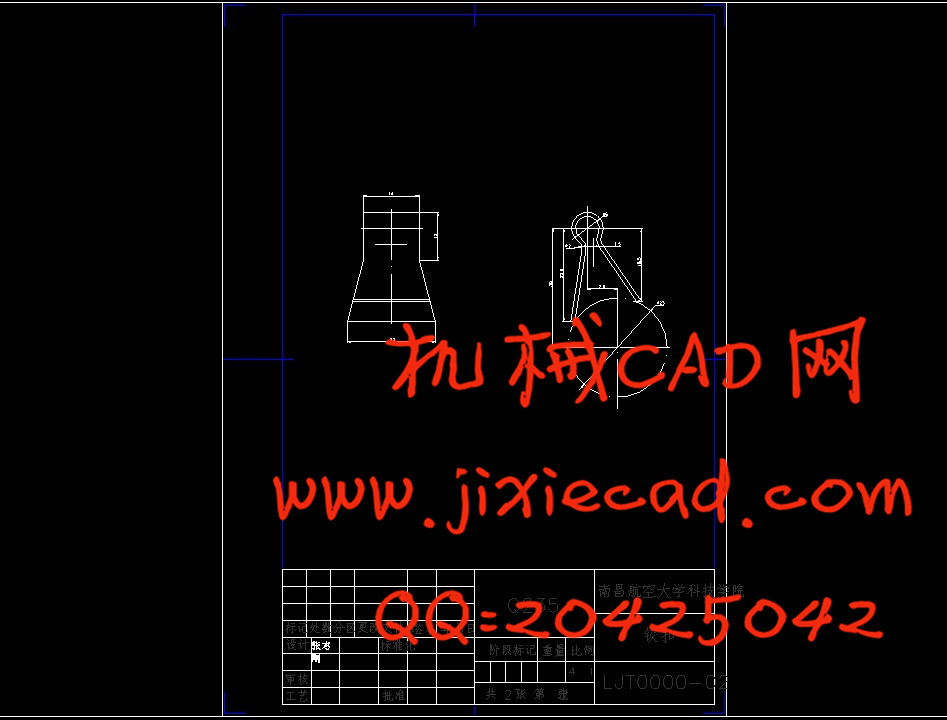

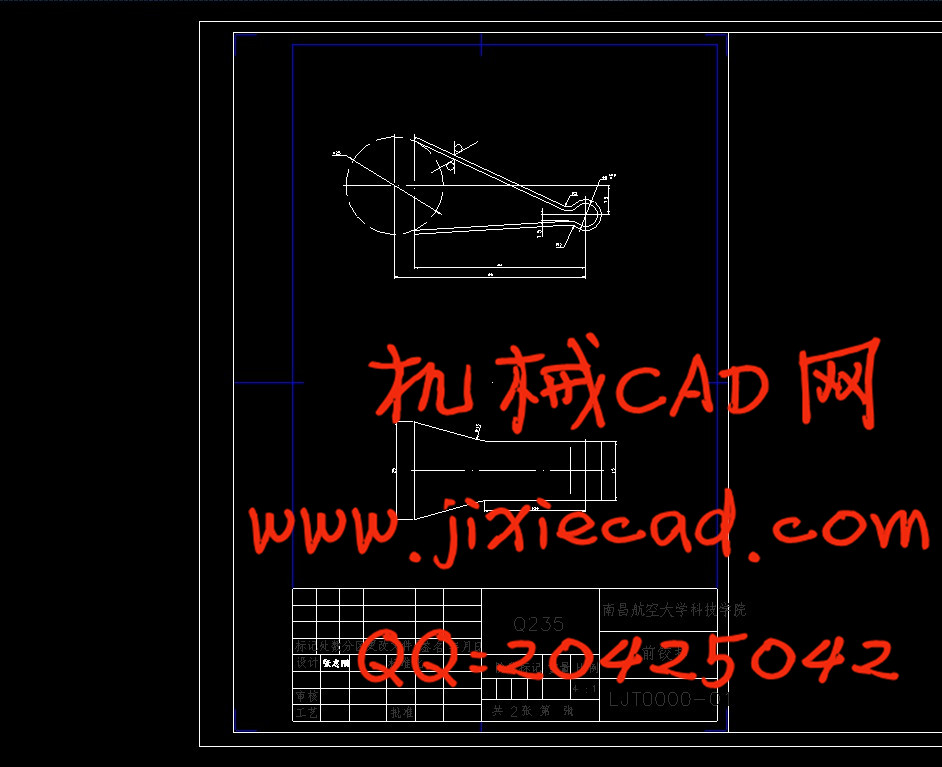

3.9.1模架……………………………………………………………………………… 19

3.9.2模座……………………………………………………………………………… 19

3.9.3模柄……………………………………………………………………………… 20

3.9.4导向装置………………………………………………………………………… 20

3.9.5卸料装置………………………………………………………………………… 21

3.9.6定位装置………………………………………………………………………… 23

3.10冲裁设备选择…………………………………………………………………… 25

3.10.1冲裁设备类型的选择………………………………………………………… 25

3.10.2压力机选用原则……………………………………………………………… 25

第四章 弯曲模设计

4.1弯曲工艺性分析与工序安排……………………………………………………… 27

4.2弯曲回弹…………………………………………………………………………… 27

4.2.1影响回弹量的因素……………………………………………………………… 27

4.2.2减少回弹量的措施……………………………………………………………… 27

4.3弯曲工艺计算……………………………………………………………………… 28

4.3.1弯曲件展开长度的确定………………………………………………………… 28

4.3.2弯曲力和顶件力计算…………………………………………………………… 29

4.3.3弯曲模工作部分尺寸计算……………………………………………………… 30

4.4弯曲模总体设计与标准件选用…………………………………………………… 34

4.4.1 U形弯曲模……………………………………………………………………… 34

4.2.2斜楔式弯曲模…………………………………………………………………… 35

4.5压力机选用………………………………………………………………………… 36

结 论……………………………………………………………………………… 37

参考文献……………………………………………………………………………… 38

致 谢……………………………………………………………………………… 39

附录A冷冲压工艺规程卡………………………………………………………………40

随着模具工业的发展,冲压技术在机械、航空、汽车、摩托车等行业中应用十分广泛,是现代工业生产的重要手段和发展方向。冲压工艺具有生产率高、生产成本低、材料利用率高、能成形复杂零件、适合大批量生产等优点,在某些领域已取代机械加工,并正逐步扩大其工艺范围。因此,冲压技术对发展生产、增强效益、更新产品等方面具有重要作用。

本课题的生产实践性非常强,所以在设计时要考虑实际生产条件。此论文的主要特点是通过设计一套模具使其同时满足两个零件的加工。首先对零件进行冲裁和弯曲工艺分析,由于零件结构简单、工艺性较好,所以属于中批量的生产采用单工序模比较好。然后确定工艺方案为落料、弯曲、最后成形,计算冲压力确定模具工作部分尺寸及公差来选取模具的结构。最后绘制落料模和弯曲模的装配图,并且拆绘一些主要零件图。本课题的关键是合理选择模具间隙和在弯曲时考虑弯曲件的回弹,这些因素对零件的质量有重要影响。

关键词:冲压模 弯曲模 冲压模具标准件 工艺分析 冲压模间隙

Abstract: Stamping die plays a very important part in die industry, it is one of the significant process equipment industry process. The principal stamping dies are blanking die, bending die, multiple station progressive die, simple die and other die, etc.

With the development of mould industry, stamping technology is very applied extensively in the professions, such as machinery, aviation, automobile and motorcycle. It is the important means of modem industrial production and develops direction. The advantages of stamping technology such as productivity high, cost lowly, utilization high, become complex element and suit a large quantity of productive. In some fields, it has replaced machining, the technology scope is enlarging step by step. Therefore stamping technology has important role for developing production, strengthening benefit and update the product, etc.

The production practicality of this program is very strong, so you should consider actual production condition when designing. The major characteristic of this paper is to make it at the same time satisfy the processing of two elements through designing a set of mould. First you should rush to cut and bend technology analysis for the element. Since the element structure is simple and technology better, so belong to only process mould in the production of batch. Then, the technology scheme is falling to expect, bending and becoming shape finally, and calculate the stamping force structure that determines mould working partial size and tolerance to select mould. finally the assembly drawing of stamping die and bending die, and takes apart to paint some major part drawings. The key of this program selects reasonably mould gap, and when bending, consider the spring back of curved, these factors have influence for the quality of element.

Keywords: stamping die bending die standard units of stamping die technical analysis clearance of punching mould

目 录

1 绪论

1.1课题背景与研究意义……………………………………………………………… 1

1.2模具行业现状与发展趋势………………………………………………………… 1

1.3课题研究的主要内容和目标……………………………………………………… 2

1.3.1课题研究的主要内容…………………………………………………………… 2

1.3.2课题研究的主要目标…………………………………………………………… 2

2 工艺方案设计

2.1零件的工艺性分析………………………………………………………………… 3

2.2加工工艺方案的确定……………………………………………………………… 4

3 冲裁模设计

3.1毛坯尺寸计算与冲裁工艺分析…………………………………………………… 5

3.1.1毛坯尺寸计算…………………………………………………………………… 5

3.1.2冲裁工艺分析…………………………………………………………………… 6

3.2工件排样与搭边…………………………………………………………………… 6

3.2.1排样……………………………………………………………………………… 6

3.2.2搭边……………………………………………………………………………… 7

3.3冲裁间隙…………………………………………………………………………… 8

3.4冲裁力计算………………………………………………………………………… 9

3.5模具压力中心计算………………………………………………………………… 11

3.6凸、凹模刃口尺寸计算…………………………………………………………… 12

3.7凸、凹模结构设计………………………………………………………………… 15

3.7.1凸模结构设计…………………………………………………………………… 15

3.7.2凹模结构设计…………………………………………………………………… 17

3.8冲模的闭合高度…………………………………………………………………… 18

3.9结构件与标准件选用……………………………………………………………… 19

3.9.1模架……………………………………………………………………………… 19

3.9.2模座……………………………………………………………………………… 19

3.9.3模柄……………………………………………………………………………… 20

3.9.4导向装置………………………………………………………………………… 20

3.9.5卸料装置………………………………………………………………………… 21

3.9.6定位装置………………………………………………………………………… 23

3.10冲裁设备选择…………………………………………………………………… 25

3.10.1冲裁设备类型的选择………………………………………………………… 25

3.10.2压力机选用原则……………………………………………………………… 25

第四章 弯曲模设计

4.1弯曲工艺性分析与工序安排……………………………………………………… 27

4.2弯曲回弹…………………………………………………………………………… 27

4.2.1影响回弹量的因素……………………………………………………………… 27

4.2.2减少回弹量的措施……………………………………………………………… 27

4.3弯曲工艺计算……………………………………………………………………… 28

4.3.1弯曲件展开长度的确定………………………………………………………… 28

4.3.2弯曲力和顶件力计算…………………………………………………………… 29

4.3.3弯曲模工作部分尺寸计算……………………………………………………… 30

4.4弯曲模总体设计与标准件选用…………………………………………………… 34

4.4.1 U形弯曲模……………………………………………………………………… 34

4.2.2斜楔式弯曲模…………………………………………………………………… 35

4.5压力机选用………………………………………………………………………… 36

结 论……………………………………………………………………………… 37

参考文献……………………………………………………………………………… 38

致 谢……………………………………………………………………………… 39

附录A冷冲压工艺规程卡………………………………………………………………40