设计简介

摘要

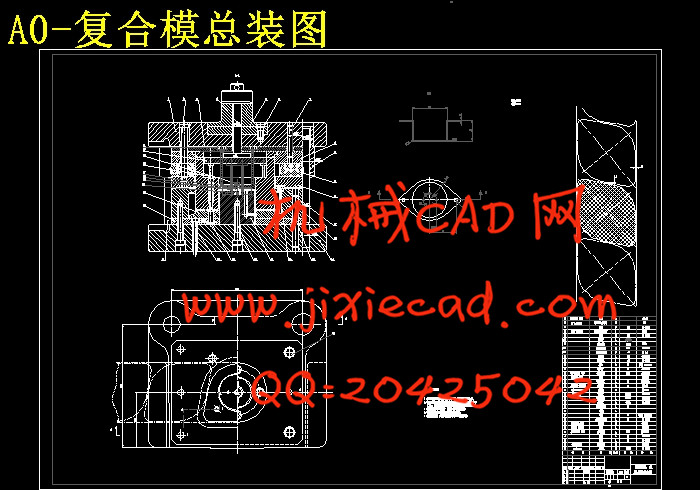

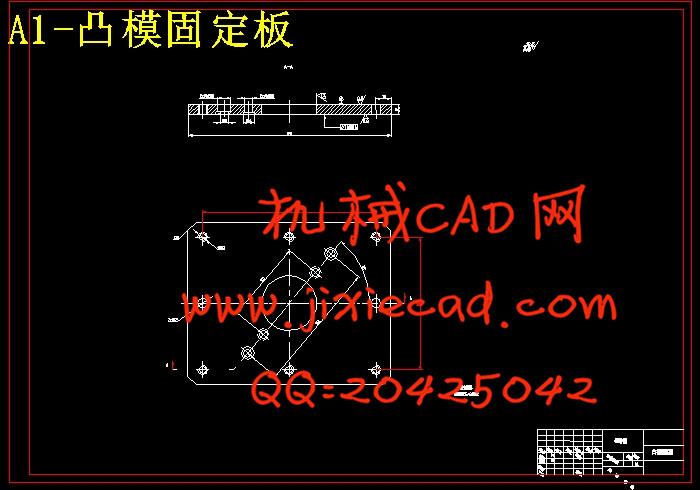

冲压模具在实际工业生产中应用广泛。在传统的工业生产中,工人生产的劳动强度大、劳动量大,严重影响生产效率的提高。随着当今科技的发展, 工业生产中模具的使用已经越来越引起人们的重视,而被大量应用到工业生产中来。冲压模具的自动送料技术也投入到实际的生产中,冲压模具可以大大的提高劳动生产效率,减轻工人负担,具有重要的技术进步意义和经济价值。本文针对端盖的冲裁工艺性和拉深工艺性,分析比较了成形过程的三种不同冲压工艺(单工序、复合工序和连续工序),确定用一幅复合模完成落料、拉深和冲孔的工序过程。介绍了端盖冷冲压成形过程,经过对端盖的批量生产、零件质量、零件结构以及使用要求的分析、研究,按照不降低使用性能为前提,将其确定为冲压件,用冲压方法完成零件的加工,且简要分析了坯料形状、尺寸,排样、裁板方案,拉深次数,冲压工序性质、数目和顺序的确定。进行了工艺力、压力中心、模具工作部分尺寸及公差的计算,并设计出模具。还具体分析了模具的主要零部件(如凸凹模、卸料装置、拉深凸模、垫板、凸模固定板等)的设计与制造,冲压设备的选用,凸凹模间隙调整和编制一个重要零件的加工工艺过程。列出了模具所需零件的详细清单,并给出了合理的装配图。

关键词:端盖;模具设计;复合模;拉深冲孔;落料;模具结构

ABSTRACT

Punching die has been widely used in industrial production.In the traditional industrial production,the worker work very hard,and there are too much work,so the efficiency is low.With the development of the science and technology nowadays,the use of punching die in the industrial production gain more attention, and be used in the industrial production more and more.Self-acting feed technology of punching die is also used in production, punching die could increase the efficience of production and could alleviate the work burden,so it has significant meaning in technologic progress and economic value.

Based on the Cover of the stamping process and the deep drawing process, Comparative analysis of the process of forming three different stamping process (single processes, complex processes and continuous processes) confirm completion of a composite model blanking, drawing processes and punching process. On the cover of the cold stamping process, right after the Cover of the mass production, quality components, and the use of structural components of the analysis, research, in line with lower performance prerequisite to the identification of stampings, Stamping method used to complete the processing components, and a brief analysis of the blank shape, size, layout, the Conference Board, the number of Drawing, stamping processes in nature, number and sequence determination. For the process, the center of pressure, the die size and the tolerance of the calculation, design mold. Also analyzes the mold of the main components (such as punch and die and dump devices, drawing punch, slates, Punch plate, etc.) design and manufacturing, stamping equipment selection, punch-gap adjustment and establishment of a vital parts machining process. Die requirements set out a detailed list of parts, and gives a reasonable assembly.

Keywords: Cover; Mold design; Composite molding; Drawing Punch;Cut;Die structure

目录

摘 要 ……………………………………………………………………1

1 端盖的工艺性分析………………………………………………… 7

2 工艺方案的拟定………………………………………………… 11

2.1 计算毛坯尺寸……………………………………………… 11

2.2 确定是否需要压边圈…………………………………… 12

2.3 确定工艺方案……………………………………………… 12

3主要工艺参数的计算……………………………………………15

3.1确定排样、裁板方案………………………………………15

3.2 计算拉深次数……………………………………………… 17

3.3 计算工艺力、初选设备………………………………..…18

3.3.1 计算工艺力…………………………………….......18

3.3.2 拉深功的计算………………………………………...21

3.3.3 初选压力机…………………………………….......22

3.3.4 计算压力中心…………………………………......23

3.3.5 计算凸、凹模刃口尺寸及公差…………………23

4 模具的结构设计……………………………………………… 30

4.1模具结构形式的选择……………………………………....30

4.1.1 模架的选用…………………………………….......30

4.1.2模具的闭合高度………………………………………..31

4.2整体模具分析及草图………………………………………34

4.3模具工作部分尺寸计算…………………………………...33

4.3.1 落料凹模.……………………………………….....33

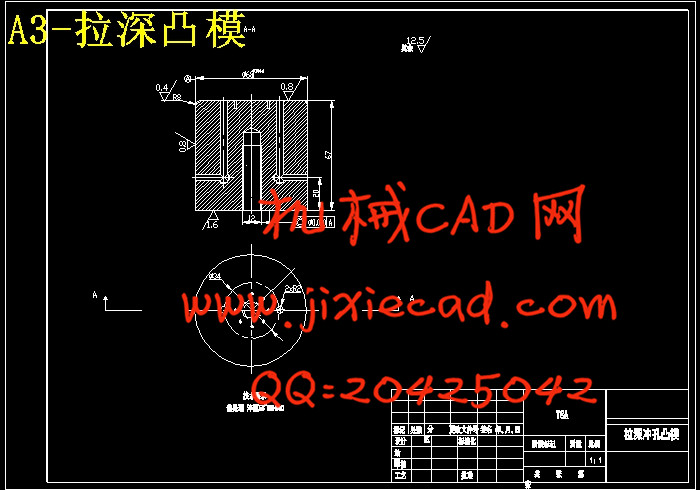

4.3.2 拉深凸模…………………………………………...34

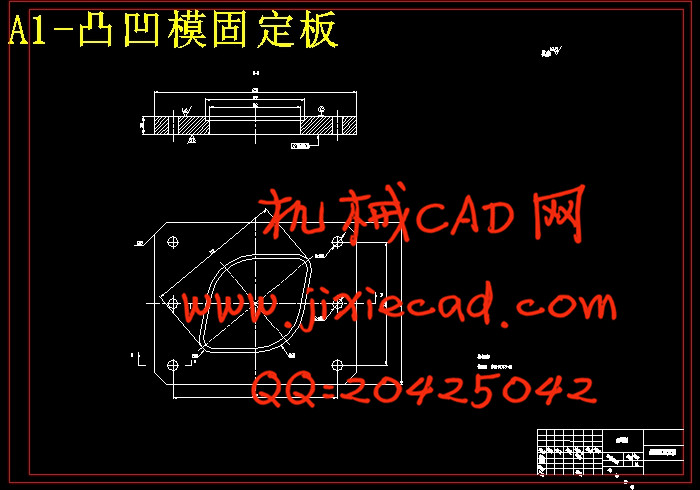

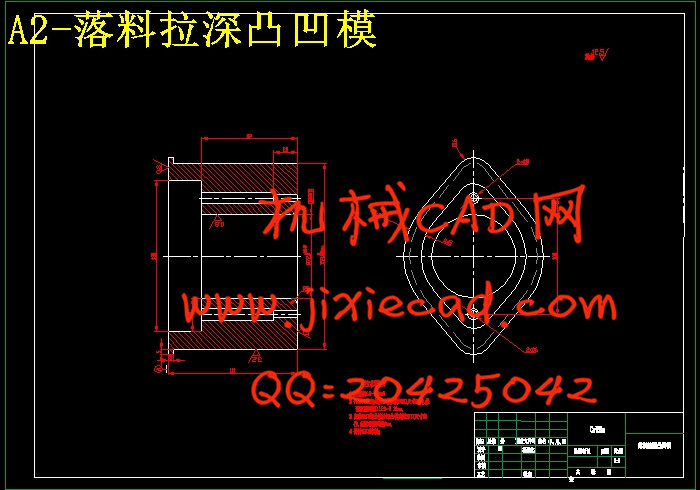

4.3.3 凸凹模……………………………………………....36

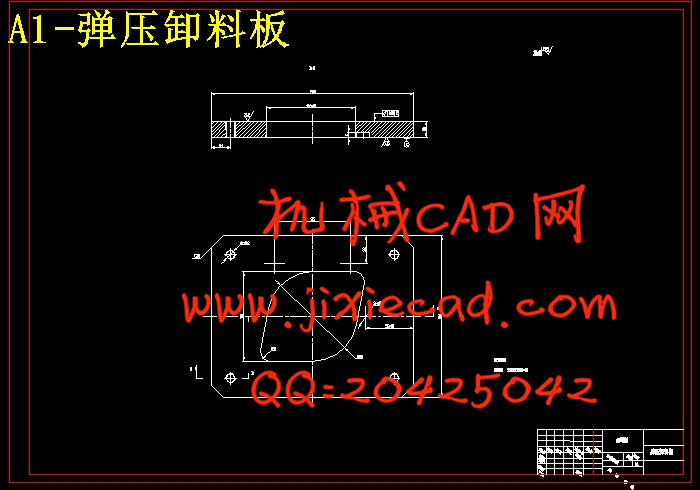

4.3.4 弹压御料板…………………………………………...38

4.3.5 上垫板……………………………………………….......40

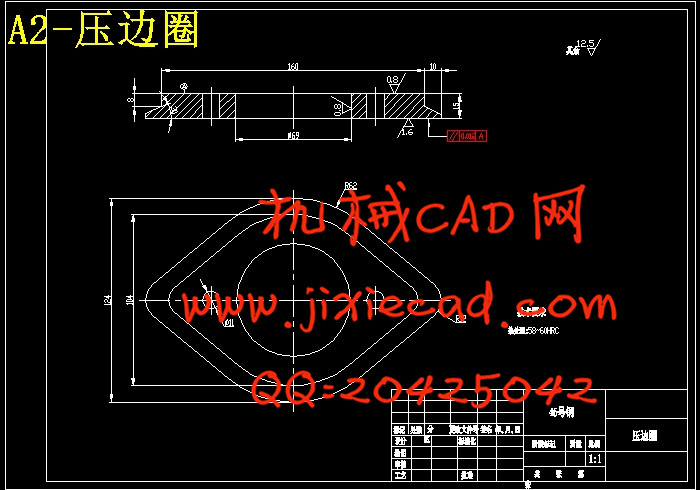

4.3.6 压边圈………………………………………………….41

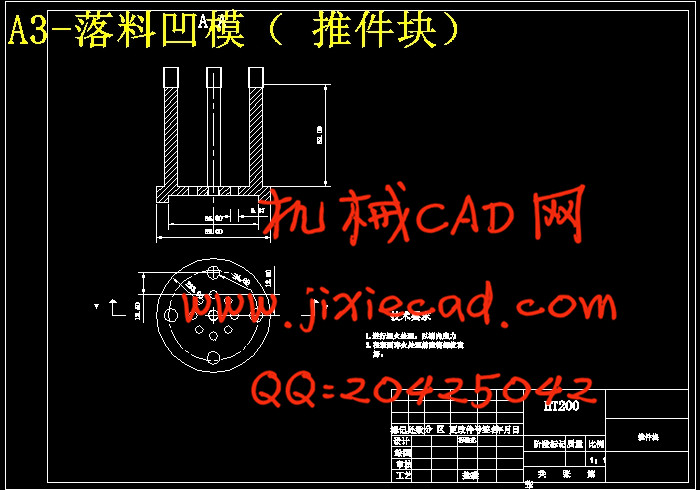

4.3.7 推件块…………………………………………………. 42

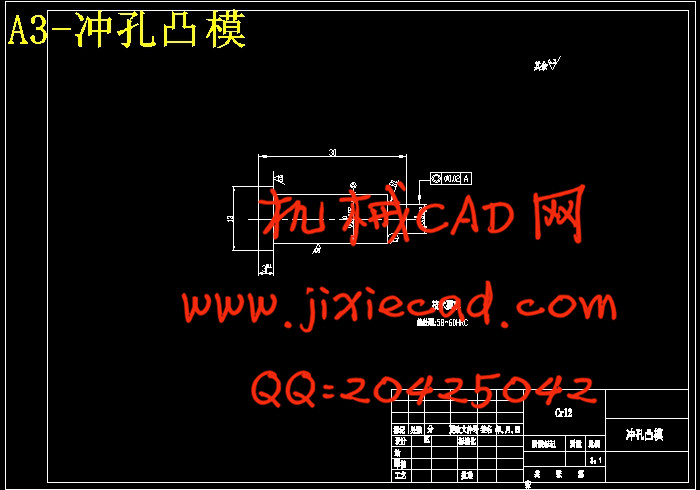

4.3.8 冲孔凹模………………………………………………. 44

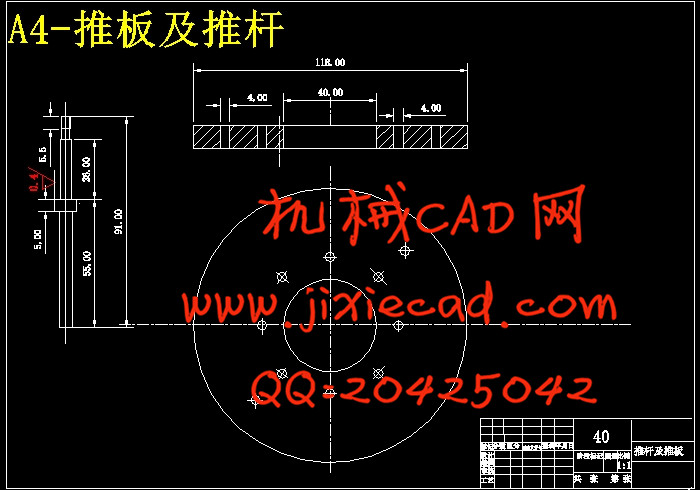

4.3.9推板及推杆……………………………………………. 46

5 模具的整体安装………………………………………………… 47

5.1 模具的总装配……………………………………………...48

5.2 模具零件…………………………………………………...... 49

6选定冲压设备………………………………………………………52

7 模具的装配………………………………………………… 53

7.1 复合模的装配……………………………….………… 53

7.2 凸、凹模间隙的调整…………………………………53

8 重要零件的加工工艺过程编制……………………… 55

结 论……………………………………………………………………60

参考文献……………………………………………………………… 61

致 谢…………………………………………………………………62