设计简介

摘 要

连杆是发动机中的高精度的精密零件,对强度有较高的要求,是汽车发动机中重要的部件之一,被称为“保安件”,其质量直接影响到发动机乃至整辆汽车的安全使用和行驶。连杆的品质直接关系到其力体部分的截面多为圆形或工字形,两端有孔,孔内装有青铜衬套或滚针轴承,供装入轴销而学性能及使用寿命,锻造连杆具有力学性能优良、易于加工、表面质量好等优点,而且生产周期短,生产工艺稳定。

连杆机构中两端分别与主动和从动构件铰接以传递运动和力的杆件。例如在往复活塞式动力机械和压缩机中,用连杆来连接活塞与曲柄。连杆多为钢件,其主构成铰接。连杆是汽车发动机中的重要零件,它连接着活塞和曲轴,其作用是将活塞的往复运动转变为曲轴的旋转运动,并把作用在活塞上的力传给曲轴以输出功率。连杆在工作中,除承受燃烧室燃气产生的压力外,还要承受纵向和横向的惯性力。因此,连杆在一个复杂的应力状态下工作。它既受、交变的拉压应力、又受弯曲应力。 连杆的主要损坏形式是疲劳断裂和过量变形。通常疲劳断裂的部位是在连杆上的三个高应力区域。连杆的工作条件要求连杆具有较高的强度和抗疲劳性能;又要求具有足够的钢性和韧性。连杆材料一般采用45钢、40Cr或40MnB等调质钢。合金钢虽具有很高强度,担对应力集中很敏感。所以,在连杆外形、过度圆角等方面需严格要求,还应注意表面加工质量以提高疲劳强度,否则高强度合金钢的应用并不能达到预期果。

连杆的生产方式多种多样,常见的为一模一件。而对于一模两件多为采用对排。本文较为系统地阐述了汽车连杆锻模的设计过程,并对模具进行了造型。

关键字:模具 开式模锻 闭式模锻 飞边槽

Abstract

Linkage is the engine of high-precision precision components, the strength of higher demand, a car engine in one of the important parts, known as the "security case", its direct impact on the quality of motor vehicles and the security of the whole Use and traffic. Link directly related to the quality of its cross-section of part of the round or more for the shape, at both ends of a hole, the hole with bronze bushings or needle roller bearings for axle load and sales of property and life, forging Linkage with good mechanical properties and easy processing, the advantages of good quality surface, and the short production cycle, the production process stability.

Linkage with the two ends of the active and passive components hinged to convey movement and of the bar. For example, in Reciprocating power machinery and compressors, with link to connect the Pistons and crank. Link for more steel parts, which constitute the main hinged. Linkage is important in the automobile engine parts, it connects with the Pistons and the crankshaft, the Pistons will play the role of the reciprocating movement into the rotating crankshaft, and the role of the Detroit Pistons passed on the crank to power output. Link in their work, in addition to the gas chamber under pressure, we must also bear the vertical and horizontal inertial force. Therefore, the link in a complex work under stress. It subject, alternating the tension and compression stress, the bending stress. Linkage is the main form of damage and excessive fatigue fracture deformation. Fatigue fracture is usually the site of the linkage of the three high stress on the region. Linkage of the terms and conditions of the link with high intensity and anti-fatigue properties and require adequate steel and toughness. Linkage of the general use of 45 steel, 40 Cr or 40 MnB, such as quenched and tempered steel. Although the strength of high-alloy steel, Tam is very sensitive to stress concentration. Therefore, the link shape, fillet over the areas to be strict requirements, attention should be paid to the surface processing to enhance the quality of fatigue, or the application of high-strength alloy steel and can not achieve the desired fruit.

Linkage of production varied, the common mode for a one. For more than two-one for the introduction of the row. This article is more systematically on the car side-by-side double-linkage of the forging process and die design process, a mold and shape

目录

中文摘要 …………………………………………………………1

英文摘要 …………………………………………………………1

1 绪论………………………………………………………………3

1.1 问题的提出及研究意义 ……………………………………3

1.2 国内外研究状况 ……………………………………………3

2 模锻工艺简述……………………………………………………4

2.1模具对金属变形的影响 ………………………………………4

2.2模锻的分类及各自的特点 ……………………………………5

2.2.1 开式模锻………………………………………………………5

2.2.2 闭式模锻………………………………………………………5

2.2.3 挤压……………………………………………………………6

2.2.4 顶镦……………………………………………………………6

3 工艺性分析及工艺方案的选择……………………………………6

3.1汽车连杆工艺性分析……………………………………………6

3.2汽车连杆工艺方案选择…………………………………………7

4 汽车连杆的工艺参数及设计计算…………………………………8

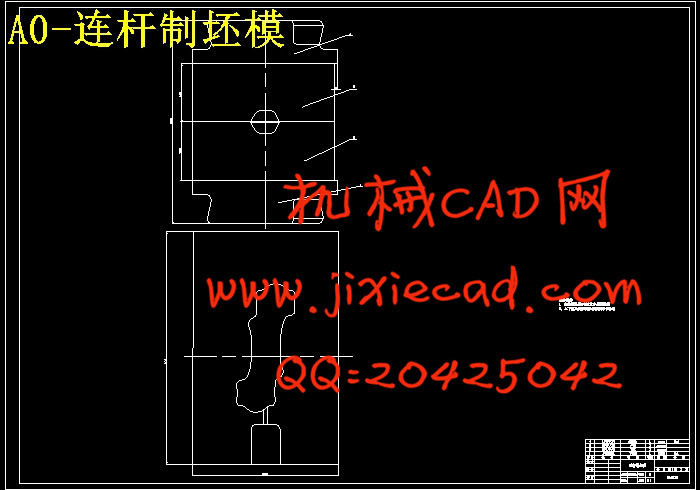

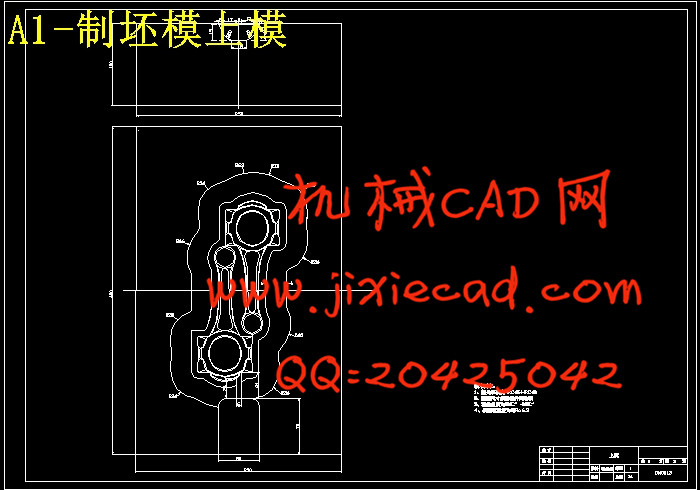

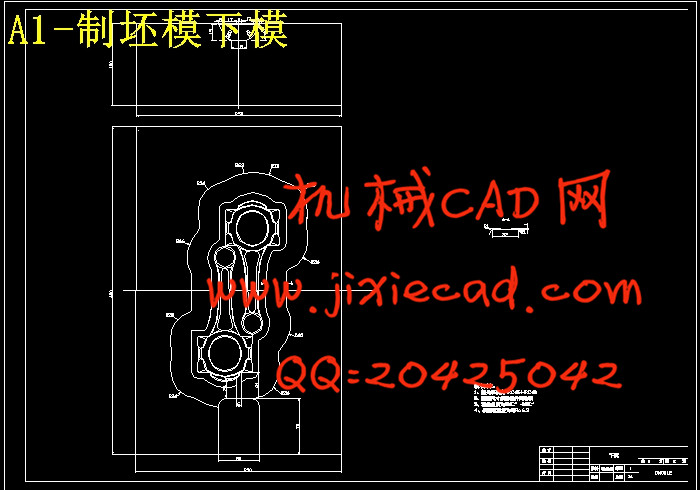

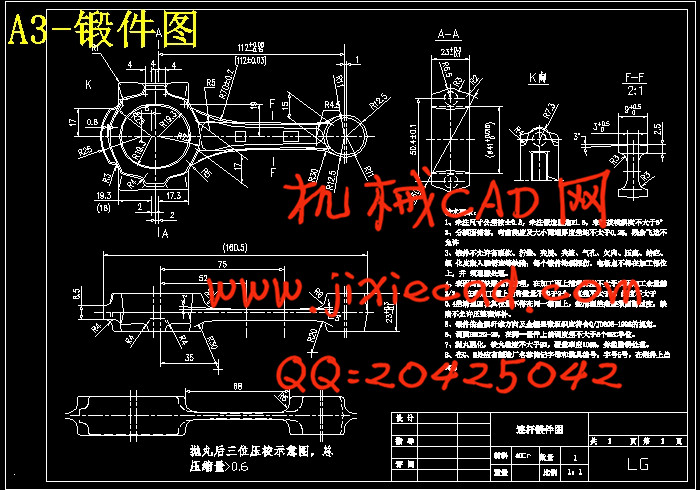

4.1 锻件图设计………………………………………………………8

4.2 计算锻件主要参数 ……………………………………………10

4.3锻锤吨位的确定…………………………………………………10

4.4确定飞边槽的形式和尺寸………………………………………10

4.1.1分模位置…………………………………………………………10

4.1.2确定公差和余量……………………………………………………10

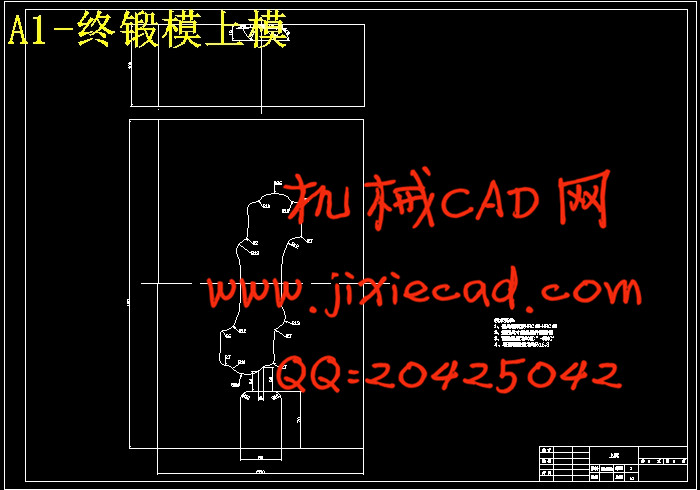

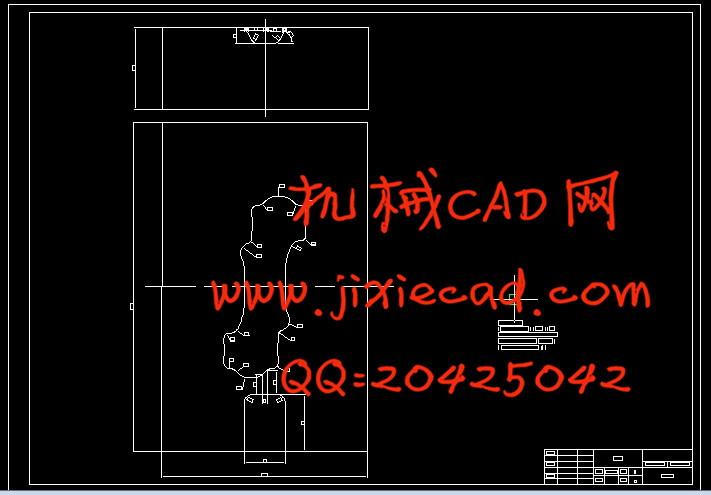

4.5终锻模膛设计……………………………………………………11

4.6钳口的设计………………………………………………………12

4.7 预锻模膛设计……………………………………………………12

4.8绘制计算毛坯图…………………………………………………13

4.9确定坯料尺寸……………………………………………………14

5 锻造模具的设计……………………………………………………14

5.1模具设计的基本作用……………………………………………14

5.2降低模具生产成本的措施………………………………………15

5.3模具的重要作用……………………………………………………17

5.4模具的设计要求……………………………………………………17

5.5模具的设计内容……………………………………………………17

5.6模具材料的选取……………………………………………………18

5.7锻造模块的确定……………………………………………………18

5.8、燕尾及键槽的选…………………………………………………18

6 汽车连杆成形工艺过程分析 ………………………………………18

6.1 毛坯的制备………………………………………………………18

6.2润滑剂的选用………………………………………………………19

6.3模具的预热…………………………………………………………20

6.4锻造温度范围的确定………………………………………………20

7 结论与展望………………………………………………………21

7.1主要结论………………………………………………………21

7.2后续研究工作的展望…………………………………………21

8 心得与体会………………………………………………………22

致谢…………………………………………………………………23

参考文献……………………………………………………………23

连杆是发动机中的高精度的精密零件,对强度有较高的要求,是汽车发动机中重要的部件之一,被称为“保安件”,其质量直接影响到发动机乃至整辆汽车的安全使用和行驶。连杆的品质直接关系到其力体部分的截面多为圆形或工字形,两端有孔,孔内装有青铜衬套或滚针轴承,供装入轴销而学性能及使用寿命,锻造连杆具有力学性能优良、易于加工、表面质量好等优点,而且生产周期短,生产工艺稳定。

连杆机构中两端分别与主动和从动构件铰接以传递运动和力的杆件。例如在往复活塞式动力机械和压缩机中,用连杆来连接活塞与曲柄。连杆多为钢件,其主构成铰接。连杆是汽车发动机中的重要零件,它连接着活塞和曲轴,其作用是将活塞的往复运动转变为曲轴的旋转运动,并把作用在活塞上的力传给曲轴以输出功率。连杆在工作中,除承受燃烧室燃气产生的压力外,还要承受纵向和横向的惯性力。因此,连杆在一个复杂的应力状态下工作。它既受、交变的拉压应力、又受弯曲应力。 连杆的主要损坏形式是疲劳断裂和过量变形。通常疲劳断裂的部位是在连杆上的三个高应力区域。连杆的工作条件要求连杆具有较高的强度和抗疲劳性能;又要求具有足够的钢性和韧性。连杆材料一般采用45钢、40Cr或40MnB等调质钢。合金钢虽具有很高强度,担对应力集中很敏感。所以,在连杆外形、过度圆角等方面需严格要求,还应注意表面加工质量以提高疲劳强度,否则高强度合金钢的应用并不能达到预期果。

连杆的生产方式多种多样,常见的为一模一件。而对于一模两件多为采用对排。本文较为系统地阐述了汽车连杆锻模的设计过程,并对模具进行了造型。

关键字:模具 开式模锻 闭式模锻 飞边槽

Abstract

Linkage is the engine of high-precision precision components, the strength of higher demand, a car engine in one of the important parts, known as the "security case", its direct impact on the quality of motor vehicles and the security of the whole Use and traffic. Link directly related to the quality of its cross-section of part of the round or more for the shape, at both ends of a hole, the hole with bronze bushings or needle roller bearings for axle load and sales of property and life, forging Linkage with good mechanical properties and easy processing, the advantages of good quality surface, and the short production cycle, the production process stability.

Linkage with the two ends of the active and passive components hinged to convey movement and of the bar. For example, in Reciprocating power machinery and compressors, with link to connect the Pistons and crank. Link for more steel parts, which constitute the main hinged. Linkage is important in the automobile engine parts, it connects with the Pistons and the crankshaft, the Pistons will play the role of the reciprocating movement into the rotating crankshaft, and the role of the Detroit Pistons passed on the crank to power output. Link in their work, in addition to the gas chamber under pressure, we must also bear the vertical and horizontal inertial force. Therefore, the link in a complex work under stress. It subject, alternating the tension and compression stress, the bending stress. Linkage is the main form of damage and excessive fatigue fracture deformation. Fatigue fracture is usually the site of the linkage of the three high stress on the region. Linkage of the terms and conditions of the link with high intensity and anti-fatigue properties and require adequate steel and toughness. Linkage of the general use of 45 steel, 40 Cr or 40 MnB, such as quenched and tempered steel. Although the strength of high-alloy steel, Tam is very sensitive to stress concentration. Therefore, the link shape, fillet over the areas to be strict requirements, attention should be paid to the surface processing to enhance the quality of fatigue, or the application of high-strength alloy steel and can not achieve the desired fruit.

Linkage of production varied, the common mode for a one. For more than two-one for the introduction of the row. This article is more systematically on the car side-by-side double-linkage of the forging process and die design process, a mold and shape

目录

中文摘要 …………………………………………………………1

英文摘要 …………………………………………………………1

1 绪论………………………………………………………………3

1.1 问题的提出及研究意义 ……………………………………3

1.2 国内外研究状况 ……………………………………………3

2 模锻工艺简述……………………………………………………4

2.1模具对金属变形的影响 ………………………………………4

2.2模锻的分类及各自的特点 ……………………………………5

2.2.1 开式模锻………………………………………………………5

2.2.2 闭式模锻………………………………………………………5

2.2.3 挤压……………………………………………………………6

2.2.4 顶镦……………………………………………………………6

3 工艺性分析及工艺方案的选择……………………………………6

3.1汽车连杆工艺性分析……………………………………………6

3.2汽车连杆工艺方案选择…………………………………………7

4 汽车连杆的工艺参数及设计计算…………………………………8

4.1 锻件图设计………………………………………………………8

4.2 计算锻件主要参数 ……………………………………………10

4.3锻锤吨位的确定…………………………………………………10

4.4确定飞边槽的形式和尺寸………………………………………10

4.1.1分模位置…………………………………………………………10

4.1.2确定公差和余量……………………………………………………10

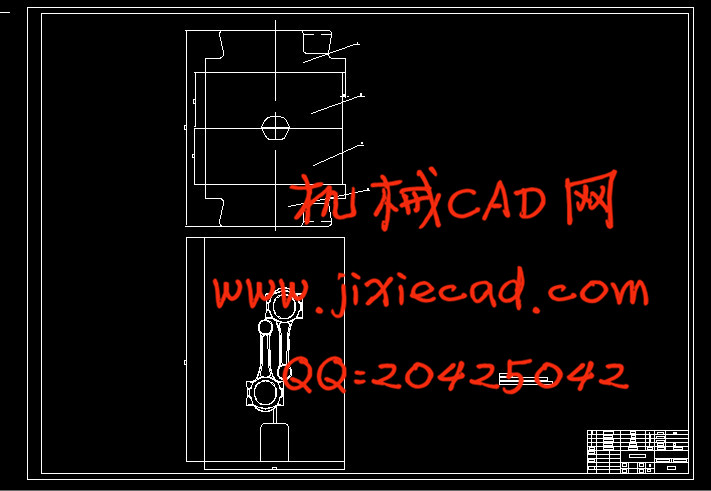

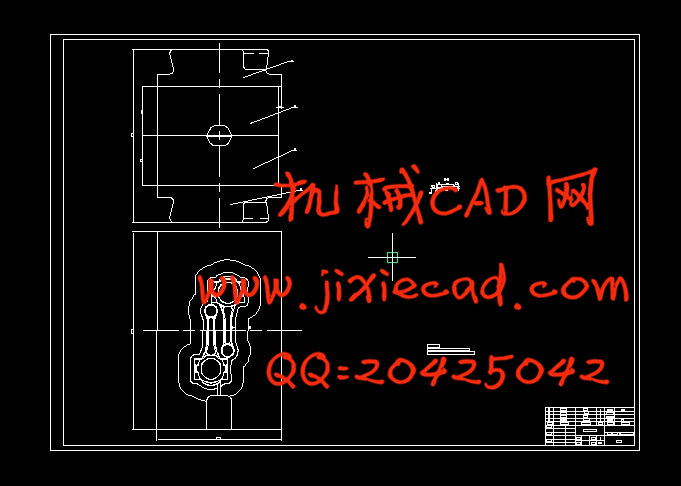

4.5终锻模膛设计……………………………………………………11

4.6钳口的设计………………………………………………………12

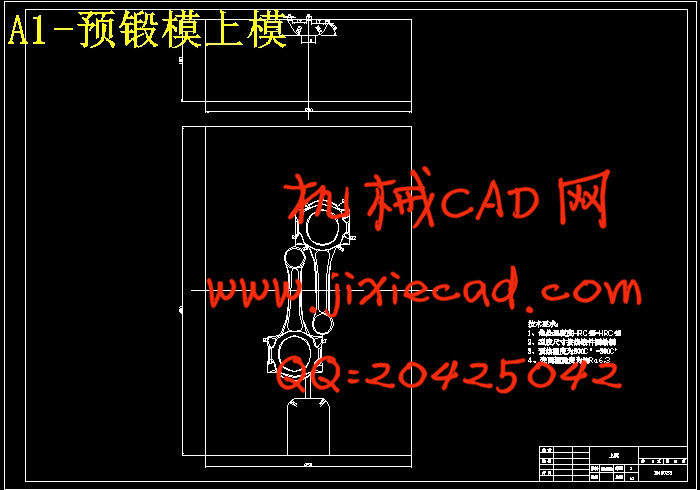

4.7 预锻模膛设计……………………………………………………12

4.8绘制计算毛坯图…………………………………………………13

4.9确定坯料尺寸……………………………………………………14

5 锻造模具的设计……………………………………………………14

5.1模具设计的基本作用……………………………………………14

5.2降低模具生产成本的措施………………………………………15

5.3模具的重要作用……………………………………………………17

5.4模具的设计要求……………………………………………………17

5.5模具的设计内容……………………………………………………17

5.6模具材料的选取……………………………………………………18

5.7锻造模块的确定……………………………………………………18

5.8、燕尾及键槽的选…………………………………………………18

6 汽车连杆成形工艺过程分析 ………………………………………18

6.1 毛坯的制备………………………………………………………18

6.2润滑剂的选用………………………………………………………19

6.3模具的预热…………………………………………………………20

6.4锻造温度范围的确定………………………………………………20

7 结论与展望………………………………………………………21

7.1主要结论………………………………………………………21

7.2后续研究工作的展望…………………………………………21

8 心得与体会………………………………………………………22

致谢…………………………………………………………………23

参考文献……………………………………………………………23