设计简介

摘 要

随着全球经济一体化的深入,模具工业在国民经济中所发挥的作用越来越明显。模具设计水平的高低直接影响产品的质量。冲压是利用安装在冲压设备(主要是压力机)上的模具对材料施加压力,使其产生分离或塑性变形,从而获得所需零件(俗称冲压或冲压件)的一种压力加工方法。冲压通常是在常温下对材料进行冷变形加工,且主要采用板料来加工成所需零件,所以也叫冷冲压或板料冲压。冲压是材料压力加工或塑性加工的主要方法之一,隶属于材料成型工程术。

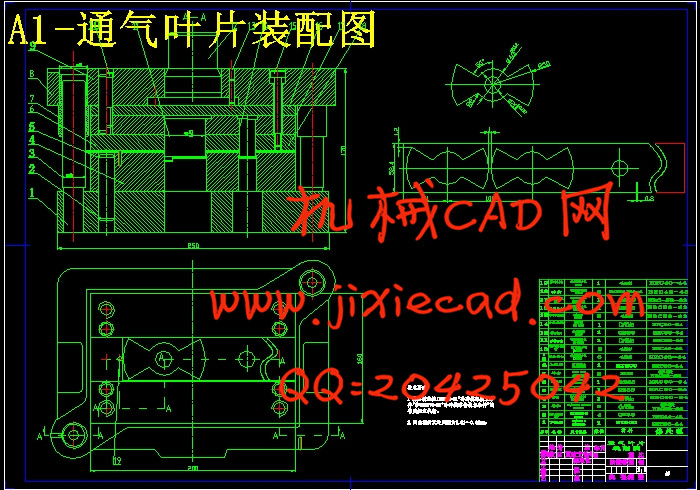

该扇形通气叶片是汽车发动机内部零件,它是汽车运行过程控制气体流动及速度的控制核心,在大多数发动机中起着重要作用.被控对象都是功率的执行器件功率接口技术已是该通气叶片发动机系统应用中的一项关键技术。设计中分析了通气叶片零件的结构及工艺性,拟订该零件的冲压工艺为“冲孔—落料”,讨论了复杂冲裁零件毛坯展开形状和尺寸的确定方法。对关键零件的结构设计作了详细阐述,并指出了模具设计时的注意事项

落料模是本设计的重点,将落料冲孔集中于一套模具中,使得冲件的质量和生产效率较高,满足了生产需要。通过超链接使其能在AutoCAD环境下方便调用,由此将传统的模具CAD从计算机辅助绘图提升到计算机辅助设计层次。

关键词:冲压工艺;级进模的采用;AutoCAD软件的运用;

Abstract

With the deepening of the global economic integration, mould industry in the national economy role of more and more apparent. Die design level directly influence the quality of the products. Stamping is to use in stamping equipment installation (mainly press) of the mould pressure on the material, make its produce separation or plastic deformation, and will obtain the needed parts (known as press or stamping) of a pressure processing method. Stamping is usually at normal temperature on the material deformation processing, cold and mainly USES the sheet metal processing into the parts, so also called cold stamping or sheet

metal stamping. Stamping is material processing or plastic processing pressure is one of the main methods in material molding engineering method.

The fan ventilation is the car engine blades of the internal parts, it is the operation process control and speed of the gas flow control core and in most plays an important role in the engine. The controlled object is the power of the executive device interface technology has is the power of the application of engine system ventilation leaves a key technology. Design of the ventilation of the leaf analysis parts structure and technology, and formulate the components of the stamping process for "punching-dropping material," discusses complex cutting parts 。blank development method to determine the shape and size. The key parts of the structure design were discussed in detail, and points out that the mould design considerations.

Dropping material-punching progressive die is the focus of this design, will blanking punching focused on a set of mould, make the salt pieces of quality and production efficiency is higher, meet the needs of production. Through the links to make it in AutoCAD environment, which will call for the traditional mould CAD in computer assistant drawing to ascend to the computer aided design level.

Key words:Stamping process;use of progressiving; AutoCAD the use of software;

目 录

摘 要 1

ABSTRACT 2

引 言 3

第一章:设计任务书 4

1.1冲裁模设计题目: 4

1.2零件的工艺性分析: 5

第二章:确定冲裁工艺方案分析 6

2.1冲压工艺方案种类 6

2.2工艺方案的比较 6

第三章 确定模具总体结构方案 7

3.1 模具类型 7

3.2 操作与定位方式 7

3.3 卸料与出件方式 7

第四章 模具与设计计算 8

4.1排样设计与计算 8

4.2计算冲压力与压力中心 9

4.3压力机的选择 9

4.4计算凸、凹模刃口尺寸及公差 10

第五章 设计选用模具零件 部件 绘制模具总装配图 11

5.1凹模设计: 11

5.2凸模设计 11

5.3有关模具设计计算 12

第六节 绘制正规模具总装配图和非标准模具零件图 14

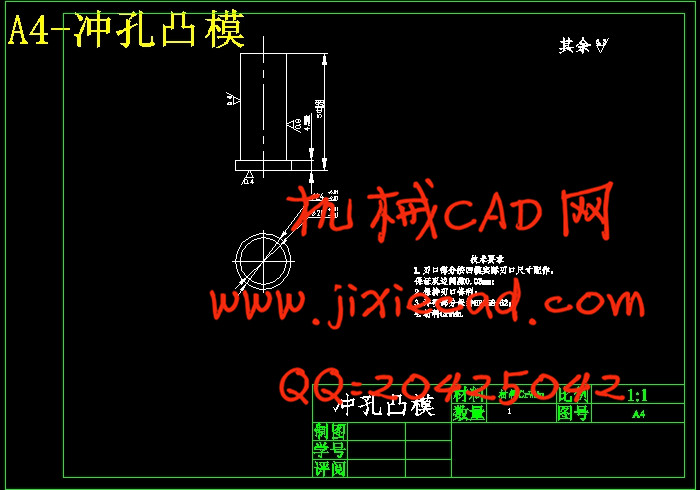

6.1大冲孔凸模 15

6.2落料凸模 16

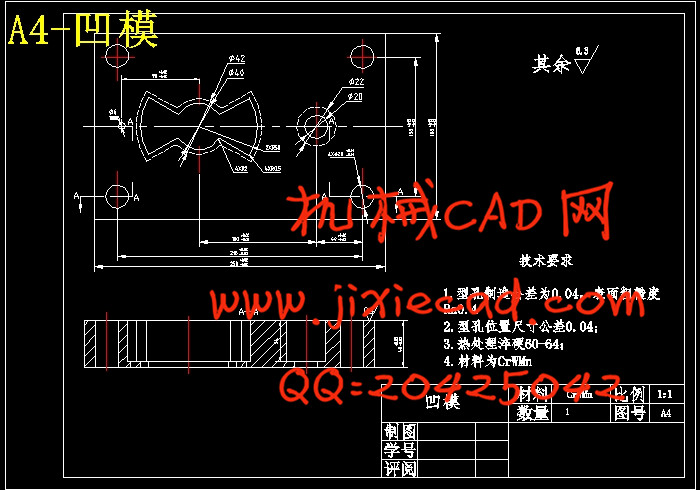

6.3凹模 17

6.4凸模固定板 18

6.5弹性卸料板 19

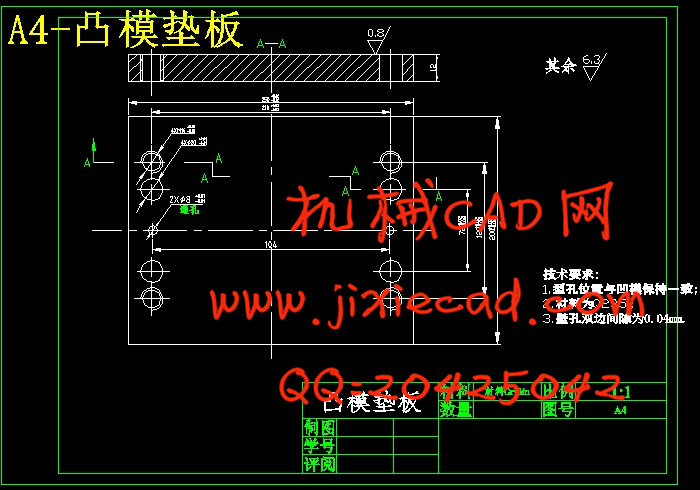

6.6凸模垫板 20

第七章 制定模具零件加工工艺过程 21

7.1凹模加工工艺过程 21

7.2落料凸模加工工艺过程 22

7.3凸模固定板加工工艺过程 22

7.4卸料板加工工艺过程 23

第八章 模具的装配 24

8.1上模装配 24

8.2下模装配 24

设计小结 25

致 谢 25

参考文献 26

随着全球经济一体化的深入,模具工业在国民经济中所发挥的作用越来越明显。模具设计水平的高低直接影响产品的质量。冲压是利用安装在冲压设备(主要是压力机)上的模具对材料施加压力,使其产生分离或塑性变形,从而获得所需零件(俗称冲压或冲压件)的一种压力加工方法。冲压通常是在常温下对材料进行冷变形加工,且主要采用板料来加工成所需零件,所以也叫冷冲压或板料冲压。冲压是材料压力加工或塑性加工的主要方法之一,隶属于材料成型工程术。

该扇形通气叶片是汽车发动机内部零件,它是汽车运行过程控制气体流动及速度的控制核心,在大多数发动机中起着重要作用.被控对象都是功率的执行器件功率接口技术已是该通气叶片发动机系统应用中的一项关键技术。设计中分析了通气叶片零件的结构及工艺性,拟订该零件的冲压工艺为“冲孔—落料”,讨论了复杂冲裁零件毛坯展开形状和尺寸的确定方法。对关键零件的结构设计作了详细阐述,并指出了模具设计时的注意事项

落料模是本设计的重点,将落料冲孔集中于一套模具中,使得冲件的质量和生产效率较高,满足了生产需要。通过超链接使其能在AutoCAD环境下方便调用,由此将传统的模具CAD从计算机辅助绘图提升到计算机辅助设计层次。

关键词:冲压工艺;级进模的采用;AutoCAD软件的运用;

Abstract

With the deepening of the global economic integration, mould industry in the national economy role of more and more apparent. Die design level directly influence the quality of the products. Stamping is to use in stamping equipment installation (mainly press) of the mould pressure on the material, make its produce separation or plastic deformation, and will obtain the needed parts (known as press or stamping) of a pressure processing method. Stamping is usually at normal temperature on the material deformation processing, cold and mainly USES the sheet metal processing into the parts, so also called cold stamping or sheet

metal stamping. Stamping is material processing or plastic processing pressure is one of the main methods in material molding engineering method.

The fan ventilation is the car engine blades of the internal parts, it is the operation process control and speed of the gas flow control core and in most plays an important role in the engine. The controlled object is the power of the executive device interface technology has is the power of the application of engine system ventilation leaves a key technology. Design of the ventilation of the leaf analysis parts structure and technology, and formulate the components of the stamping process for "punching-dropping material," discusses complex cutting parts 。blank development method to determine the shape and size. The key parts of the structure design were discussed in detail, and points out that the mould design considerations.

Dropping material-punching progressive die is the focus of this design, will blanking punching focused on a set of mould, make the salt pieces of quality and production efficiency is higher, meet the needs of production. Through the links to make it in AutoCAD environment, which will call for the traditional mould CAD in computer assistant drawing to ascend to the computer aided design level.

Key words:Stamping process;use of progressiving; AutoCAD the use of software;

目 录

摘 要 1

ABSTRACT 2

引 言 3

第一章:设计任务书 4

1.1冲裁模设计题目: 4

1.2零件的工艺性分析: 5

第二章:确定冲裁工艺方案分析 6

2.1冲压工艺方案种类 6

2.2工艺方案的比较 6

第三章 确定模具总体结构方案 7

3.1 模具类型 7

3.2 操作与定位方式 7

3.3 卸料与出件方式 7

第四章 模具与设计计算 8

4.1排样设计与计算 8

4.2计算冲压力与压力中心 9

4.3压力机的选择 9

4.4计算凸、凹模刃口尺寸及公差 10

第五章 设计选用模具零件 部件 绘制模具总装配图 11

5.1凹模设计: 11

5.2凸模设计 11

5.3有关模具设计计算 12

第六节 绘制正规模具总装配图和非标准模具零件图 14

6.1大冲孔凸模 15

6.2落料凸模 16

6.3凹模 17

6.4凸模固定板 18

6.5弹性卸料板 19

6.6凸模垫板 20

第七章 制定模具零件加工工艺过程 21

7.1凹模加工工艺过程 21

7.2落料凸模加工工艺过程 22

7.3凸模固定板加工工艺过程 22

7.4卸料板加工工艺过程 23

第八章 模具的装配 24

8.1上模装配 24

8.2下模装配 24

设计小结 25

致 谢 25

参考文献 26