设计简介

汽车玻璃升降器外壳零件的冲压工艺及模具设计

摘要

本设计是结合本人专业及所学的相关知识完成的。除了文字说明外还有许多图例与表格,使内容更加详尽明了。本设计以实用为本,简单明了为宗旨。共分六章:第一章.对零件的冲压工艺性分析。第二章.工艺方案的确定。第3章.工艺计算。第4章.编写冲压工艺卡片。第5章.模具工作零件的设计。第6章.编写主要零件的加工工艺。第7章.模具的装配与调试后附有参考文献和设计心得。本设计仅供学习探讨,不足之处敬请指出。

通过这次设计让我把所学的知识充分融会起来,使理论和实际结合起来,懂得了学要有所用,学会借鉴和创新才能不断的进步。

关键词:拉深模 冲裁模 凹模

Automobile glass going up and down device outer cover Pressing the craft and mold design of the part

Abstract

This design combines oneself profession and learn of related knowledge complete.Still have many diagrams example and forms in addition to the writing elucidation, make contents understood more and in details.This design with practical is originally, understand for the aim in brief.Total is divided into six chapter:Chapter 1.Hurtle to press the craft analysis to the spare parts.Chapter 2.The assurance of the craft project.Chapter 3.The craft calculation.Chapter 4.The plait writes to hurtle to press the craft card.Chapter 5.The design of the molding tool work spare parts.Chapter 6. the plait writes the main spare parts to process the craft.Chapter 7. the assemble of the molding tool with adjust to try behind fish-eye reference and design insight.This design provides the study study only, the place of the shortage points out please.

Pass to design to let this time me learn of knowledge melt well and would get up, make theories and actual knots put together, know to learn and have to use, master to draw lessons from and innovation then can continuously of progress.

Keyword: Drawing numbers Blanking die Cavity piate

目录

绪论 1

第1章 零件的冲压工艺性分析 3

1.1 零件的使用条件和技术要求 3

1.2 冲压工艺性分析 3

第2章 工艺方案的确定 4

2.1 计算坯料尺寸 4

2.2 计算拉深次数 4

2.3 冲压工艺方案的确定 5

第3章 工艺计算 7

3.1 确定排样、裁板方案 7

3.2 确定各中间工序尺寸 8

3.3 计算各工序压力、选用压力机 8

第4章 编写冲压工艺卡片 12

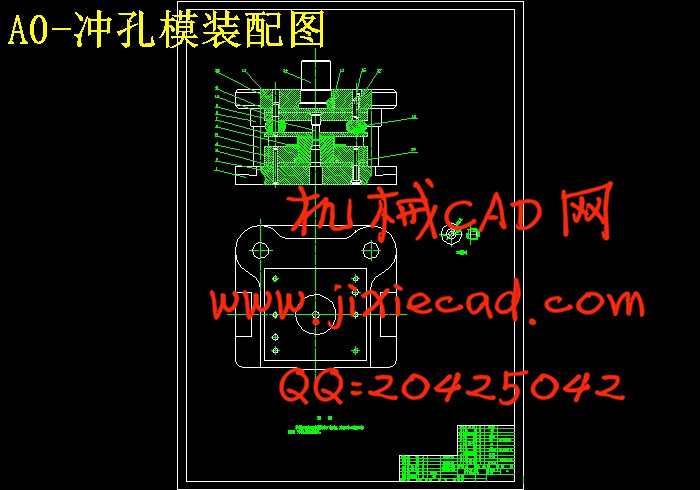

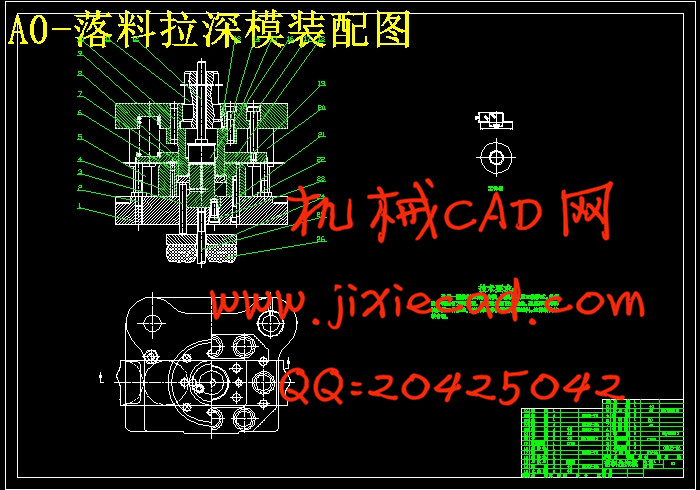

第5章 模具设计 14

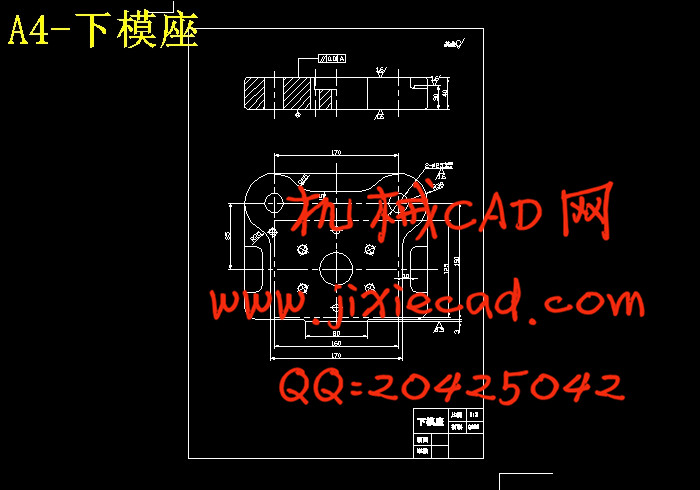

5.1 模具结构形式选择 17

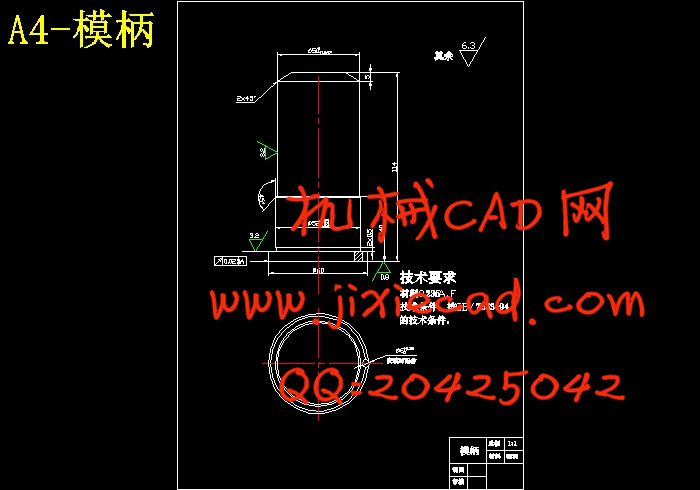

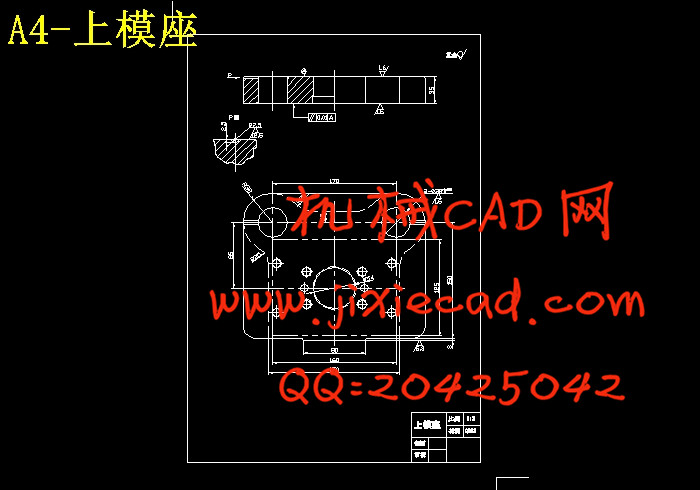

5.2 模具工作零件设计 18

5.3 模具其他零件的选取与设计 19

第6章 编写主要零件的加工工艺 20

第7章 模具的装配与调试 21

7.1 模具的装配: 22

7.2 模具的调试 23

设计总结 24

参考文献 25

致谢

摘要

本设计是结合本人专业及所学的相关知识完成的。除了文字说明外还有许多图例与表格,使内容更加详尽明了。本设计以实用为本,简单明了为宗旨。共分六章:第一章.对零件的冲压工艺性分析。第二章.工艺方案的确定。第3章.工艺计算。第4章.编写冲压工艺卡片。第5章.模具工作零件的设计。第6章.编写主要零件的加工工艺。第7章.模具的装配与调试后附有参考文献和设计心得。本设计仅供学习探讨,不足之处敬请指出。

通过这次设计让我把所学的知识充分融会起来,使理论和实际结合起来,懂得了学要有所用,学会借鉴和创新才能不断的进步。

关键词:拉深模 冲裁模 凹模

Automobile glass going up and down device outer cover Pressing the craft and mold design of the part

Abstract

This design combines oneself profession and learn of related knowledge complete.Still have many diagrams example and forms in addition to the writing elucidation, make contents understood more and in details.This design with practical is originally, understand for the aim in brief.Total is divided into six chapter:Chapter 1.Hurtle to press the craft analysis to the spare parts.Chapter 2.The assurance of the craft project.Chapter 3.The craft calculation.Chapter 4.The plait writes to hurtle to press the craft card.Chapter 5.The design of the molding tool work spare parts.Chapter 6. the plait writes the main spare parts to process the craft.Chapter 7. the assemble of the molding tool with adjust to try behind fish-eye reference and design insight.This design provides the study study only, the place of the shortage points out please.

Pass to design to let this time me learn of knowledge melt well and would get up, make theories and actual knots put together, know to learn and have to use, master to draw lessons from and innovation then can continuously of progress.

Keyword: Drawing numbers Blanking die Cavity piate

目录

绪论 1

第1章 零件的冲压工艺性分析 3

1.1 零件的使用条件和技术要求 3

1.2 冲压工艺性分析 3

第2章 工艺方案的确定 4

2.1 计算坯料尺寸 4

2.2 计算拉深次数 4

2.3 冲压工艺方案的确定 5

第3章 工艺计算 7

3.1 确定排样、裁板方案 7

3.2 确定各中间工序尺寸 8

3.3 计算各工序压力、选用压力机 8

第4章 编写冲压工艺卡片 12

第5章 模具设计 14

5.1 模具结构形式选择 17

5.2 模具工作零件设计 18

5.3 模具其他零件的选取与设计 19

第6章 编写主要零件的加工工艺 20

第7章 模具的装配与调试 21

7.1 模具的装配: 22

7.2 模具的调试 23

设计总结 24

参考文献 25

致谢