设计简介

摘要

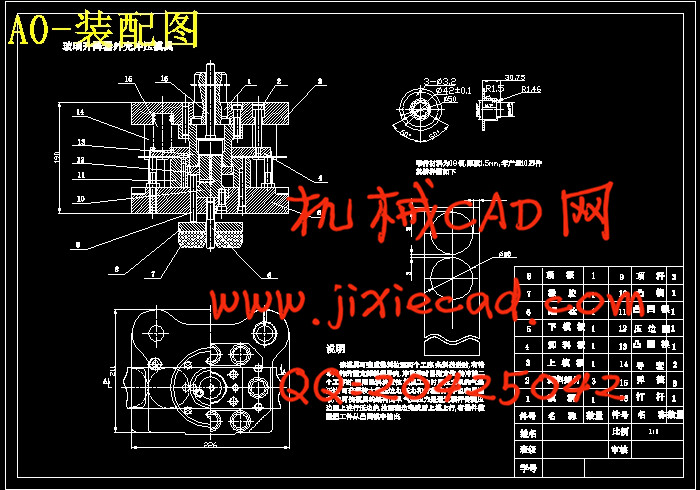

通过对汽车玻璃升降器的冲压工艺性分析,详细介绍了该模具的总体结构设计和主要成形零件的设计与制造,并介绍了其定位设计,冲裁力的计算,压力中心的计算,对排样设计方案作了比较与选择,论证了全理的排样方案,确定了条料的送进与导料方式及定距结构形式等。理论证明,该模具结构可靠,能保证产品的质量,对此类零件的模具设计有重要参考价值。

关键词:汽车玻璃升降器,复合模,工艺分析,工位排样

The automobile glass ascends and descend the machine outer shell to hurtle to press the molding tool design

Abstract

Pass the design to the automobile glass ascends and descend the machine to hurtle to press the craft analysis, detailedly introduced the total structure design of that molding tool and mainly take shape the spare parts and manufacturings, and introduced it positions the design, hurtling the calculation of cut the dint, the calculation of the pressure center, designed the project to make the comparison and choices to the row kind, argument the row kind project of whole reason, made sure that anticipate of send into with lead to anticipate the way and be apart from the structure form certainly...etc..The theories prove that the molding tool's structure credibility, can guarantee the quantity of the product, design to have the important reference value to this kind of molding tool of spare parts.

Keyword:The automobile glass ascends and descend the machine, compound mold, craft analytical, the work row kind

目 录

绪 论............................................................................................1

第一章 冲压工艺分析..............................................................1

1.1 分析零件的冲压工艺性.........................................................1

1.2 工艺方案的确定.....................................................................2

第二章 确定各中间工序尺寸及选用压力机....................6

2.1 拉深工序尺寸.........................................................................6

2.2 计算各工序压力选用压力机..................................................7

第三章 冲压工艺方案的确定................................................11

第四章 模具机构设计..............................................................11

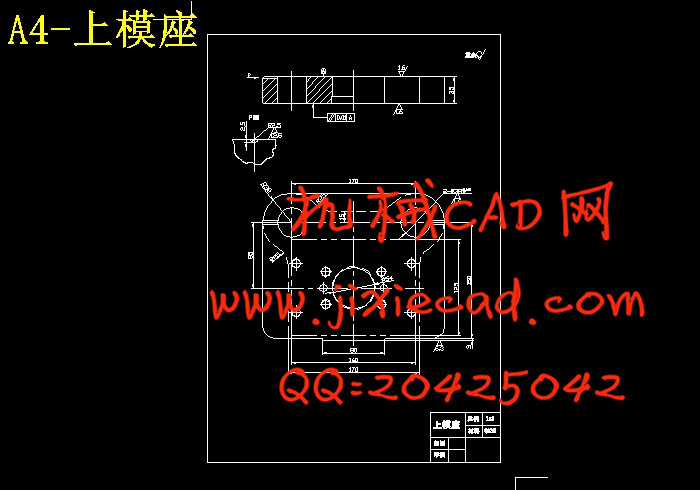

4.1模具结构形式选择..................................................................12

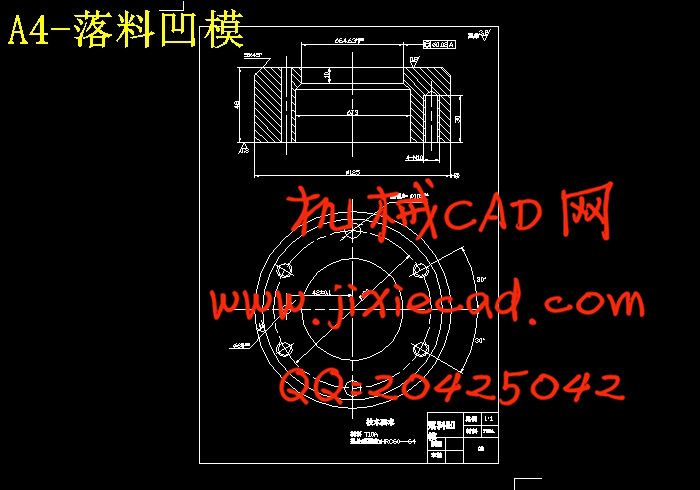

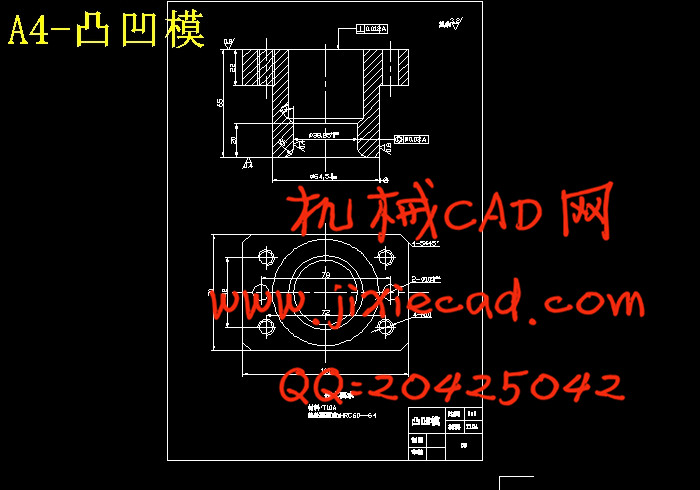

4.2模具工作零件设计..................................................................13

第五章 工作零件的加工工艺................................................16

第六章 编写冲压工艺卡片 (见表)................................16

第七章 冲压模具具的试冲与调整.......................................16

7.1 调整凸模进入凹模的深度...................................................16

7.2 调整冲裁间隙.......................................................................17

7.3 试模.......................................................................................17

7.4模具在试模过程中出现的问题及调整方法..........................17

第八章 设计总结......................................................................18

致谢.................................................................................................21

参考文献.........................................................................................22

通过对汽车玻璃升降器的冲压工艺性分析,详细介绍了该模具的总体结构设计和主要成形零件的设计与制造,并介绍了其定位设计,冲裁力的计算,压力中心的计算,对排样设计方案作了比较与选择,论证了全理的排样方案,确定了条料的送进与导料方式及定距结构形式等。理论证明,该模具结构可靠,能保证产品的质量,对此类零件的模具设计有重要参考价值。

关键词:汽车玻璃升降器,复合模,工艺分析,工位排样

The automobile glass ascends and descend the machine outer shell to hurtle to press the molding tool design

Abstract

Pass the design to the automobile glass ascends and descend the machine to hurtle to press the craft analysis, detailedly introduced the total structure design of that molding tool and mainly take shape the spare parts and manufacturings, and introduced it positions the design, hurtling the calculation of cut the dint, the calculation of the pressure center, designed the project to make the comparison and choices to the row kind, argument the row kind project of whole reason, made sure that anticipate of send into with lead to anticipate the way and be apart from the structure form certainly...etc..The theories prove that the molding tool's structure credibility, can guarantee the quantity of the product, design to have the important reference value to this kind of molding tool of spare parts.

Keyword:The automobile glass ascends and descend the machine, compound mold, craft analytical, the work row kind

目 录

绪 论............................................................................................1

第一章 冲压工艺分析..............................................................1

1.1 分析零件的冲压工艺性.........................................................1

1.2 工艺方案的确定.....................................................................2

第二章 确定各中间工序尺寸及选用压力机....................6

2.1 拉深工序尺寸.........................................................................6

2.2 计算各工序压力选用压力机..................................................7

第三章 冲压工艺方案的确定................................................11

第四章 模具机构设计..............................................................11

4.1模具结构形式选择..................................................................12

4.2模具工作零件设计..................................................................13

第五章 工作零件的加工工艺................................................16

第六章 编写冲压工艺卡片 (见表)................................16

第七章 冲压模具具的试冲与调整.......................................16

7.1 调整凸模进入凹模的深度...................................................16

7.2 调整冲裁间隙.......................................................................17

7.3 试模.......................................................................................17

7.4模具在试模过程中出现的问题及调整方法..........................17

第八章 设计总结......................................................................18

致谢.................................................................................................21

参考文献.........................................................................................22